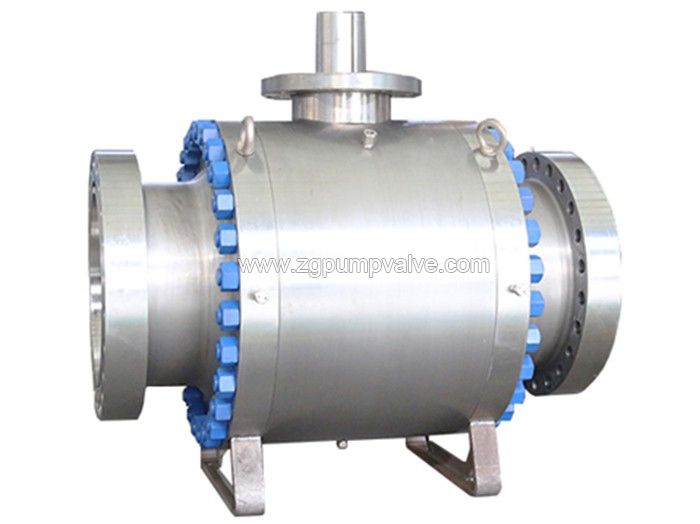

Ball valve

Ball Valve Function Basics

A ball valve functions as a quarter-turn valve, which controls flow through a hollow, perforated, and pivoting sphere, hence the name. It is in the same valve family as butterfly valves and plug valves, which are also quarter-turn valves. The sphere has a port, or a bore, in its center, which is critical to its function.

we are ball valve manufacturer and ball valve suppliers, If You Need PE ended ball valve, Welcome To Contact Us To Know More.

When the bore in the ball valve function is lined up with the associated pipeline, the valve is open, so fluid can move through the bore. Turned 90 degrees, it is situated perpendicular to the flow of the fluid, so the valve is closed and the fluid can’t come through. That being said, ball valve function is not well suited to applications in which you need to throttle the flow of a fluid.

The way a ball valve functions makes it easy to see if the valve is open or shut. The handle that operators use to adjust where the sphere is aligned with the flow when the valve is open, and it is perpendicular when the valve is closed.

Disadvantages of Ball Valve Function

As previously mentioned, ball valves are not ideal for throttling applications, as they do not allow for very fine control of flow. If you need to slow the flow of a fluid, a ball valve’s function is not a good choice — it should be used for opening or closing alone. They are also known to trap fluid in the bore when in the closed position, which can crack the valve if the liquid freezes.

One of the biggest problems with ball valve function is that it is not multipurpose. Thicker liquids like slurries also pose problems for ball valves, sticking the valve in place so it cannot open or close, and generally causing wear and tear on the valve that will rapidly reduce its lifespan. Even using a ball valve in a high-velocity flow situation can cause problems, as ball valve function is not designed to withstand this level of pressure and can cause a lot of erosion, fast.

Like most standard valves, a ball valve loses its function over time, wearing out through use. It is not a valve that will last forever by any means, so while it can be an affordable piece of equipment, it is likely something you will have to replace frequently.

If you already rely on ball valves and are questioning if their function is truly suiting your needs, or if you are considering installing ball valves as part of your industrial processes, there are alternatives that may work better for you. It all comes back to that efficiency, profitability, and success piece — ball valve function might not be what you need to accomplish that.

How It Works: Ball Valves

A ball valve is a device with a spherical closure unit that provides on-off control of flow.

Ball valves have a spherical closure unit that provides on/off control of flow. The sphere has a port (bore) through the center. When the valve is positioned such that the bore is aligned in the same direction as the pipeline, it is in the open position, and fluid can flow through it. When rotated 90°, the bore becomes perpendicular to the flow path, meaning the valve is closed, and fluid cannot pass through. Ball, butterfly, and plug valves make up the quarter-turn valve family.

People also ask

What is a ball valve used for?

The ball valve body design is conventional and flow is controlled by the position of a hole through the ball. This type of valve is used to control flow, pressure control in gas distribution systems and pressure reduction in connection with gas storage.

Sichuan Zigong Pump & Valve Co., Ltd. shorted as Zigong Pump & Valve, is the biggest chemical pump manufacturer with full specifications in West China.

Read More