Slurry Pump

-

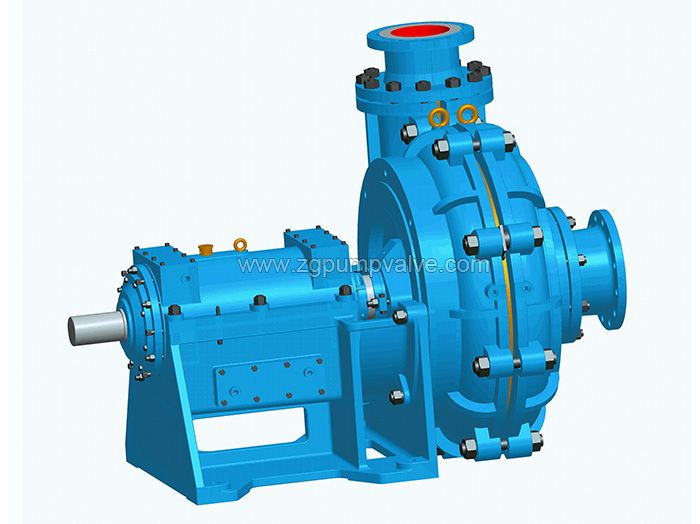

Single-layer casing slurry pump

The YMT slurry pump is an optimized design based on the theory of solid-liquid two-phase flow.

-

ZZ slurry pump is a research and development achievement for decades.

-

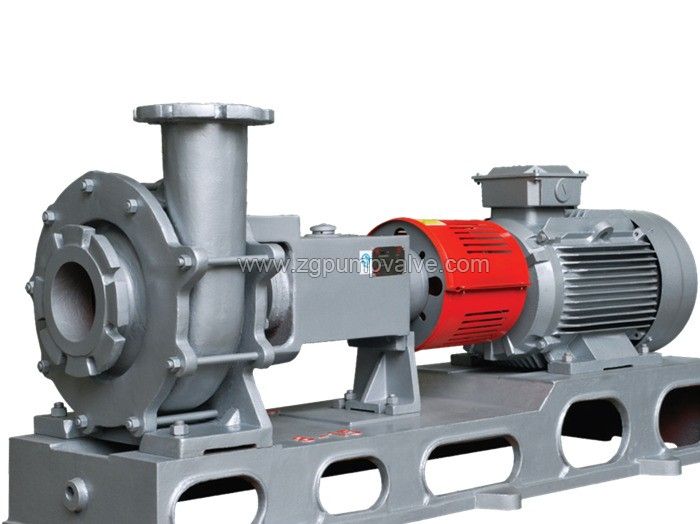

FGD flue gas desulfurization pump

Aiming at the characteristics of flue gas desulfurization project of thermal power plant

-

The ZP Series is a newly developed foam slurry pump with a unique impeller and blade design.

SLURRY PUMP

Slurry pumps are used for conveying medium which contain particles or solids. The slurry pumps used for severe working conditions should have both wear-resistant and corrosion- resistant materials to ensure reliable operation.

Pump structure and material selections should be made for trouble free performance and low wear when handling highly abrasive or corrosive medium. We manufacture a wide range of slurry pumps specially designed to convey light to severe slurry medium.

Single-layer casing slurry pump, flue gas desulfurization mixed flow pump, silicon carbide lining FGD pump, vertical submerged slurry pump, heavy duty slurry pump, they have completely different shapes and structural forms, and play the important role in their working conditions.

Here you will find some topics about slurry pumps.

Read More