Chemical industry

Application of high temperature hot water circulation pumps in chemical industry

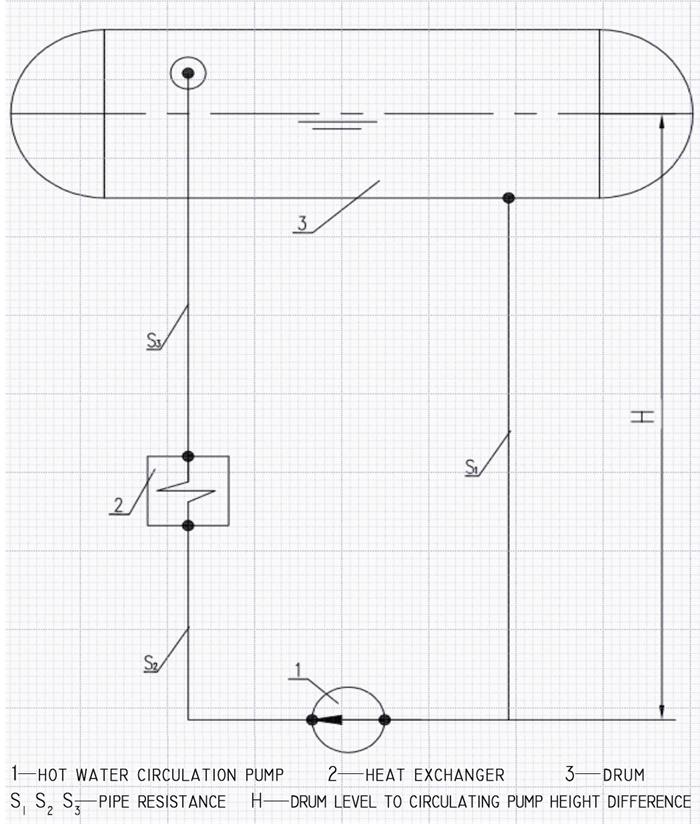

The hot water circulation pump is configured in the vaporization flue cooling system to improve the thermal power circulation of the system

Pump type: High temperature hot water circulation pump

Pump features: High temperature and high pressure, centerline mounted OH2 support

Pump parameters:

● Flow rate: 1650 m3/h

● Head: 36 m

● Pump pressure rating: 6.4 MPa

● Working pressure of pipeline after pump: 5.36 MPa

Working parameters:

Maximum evaporation of vaporizing flue is 150t/h

The rated working pressure of drum is 4.4MPa, and the working temperature of drum is 260℃

Drum level to circulating pump height H is about 60m

Pump after pipeline resistance S2 is about 10m, heat exchanger after pipeline resistance S3 is about 10m, heat exchanger resistance is about 10m

1: Hot water circulation pump

2: Heat exchanger

3: Drum

S1, S2, S3: Pipe resistance H: Drum level to circulating pump height difference

Analysis:

1. Circulation ratio of hot water circulating pump is 12~20

2. The hot water circulating pump is set in the closed-circuit circulating steam and water system, and the head need not be too high

3. The working pressure needs to consider the drum pressure and the height of the water column before the pump. The pressure rating of the hot water circulating pump is relatively high

Actual operation: the flow rate shown by the flowmeter of the pipeline behind the pump is about 1550m3/h. The gas production of vaporizing flue is about 120~135t/h.