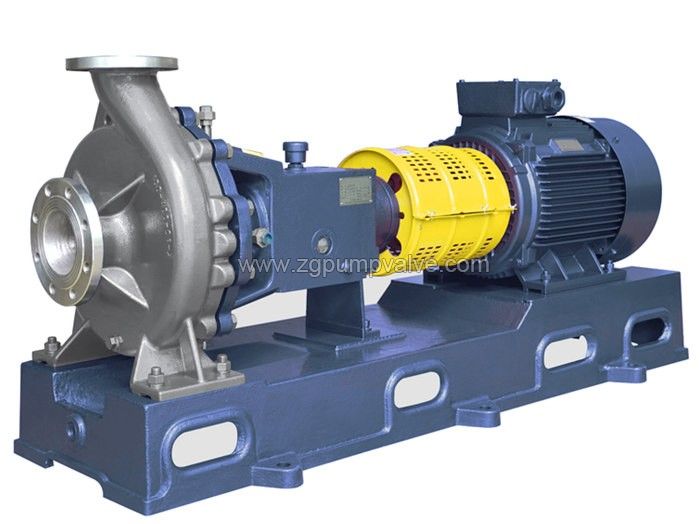

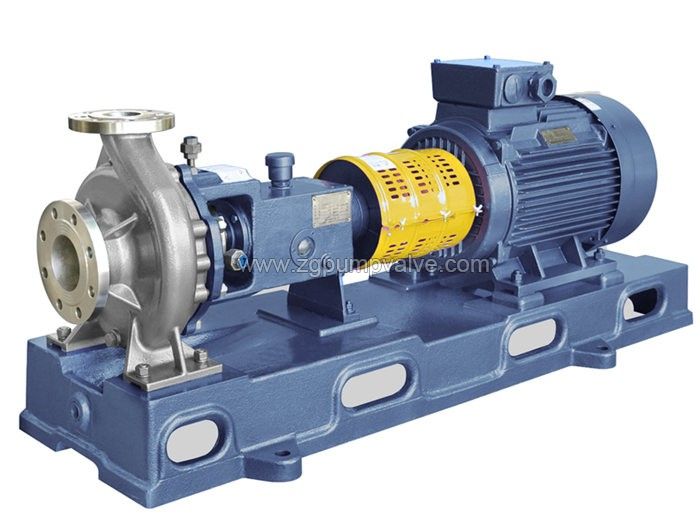

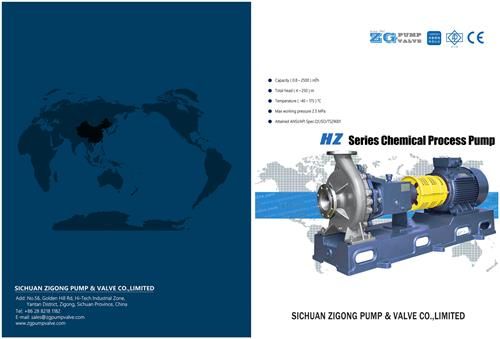

Chemical Pump

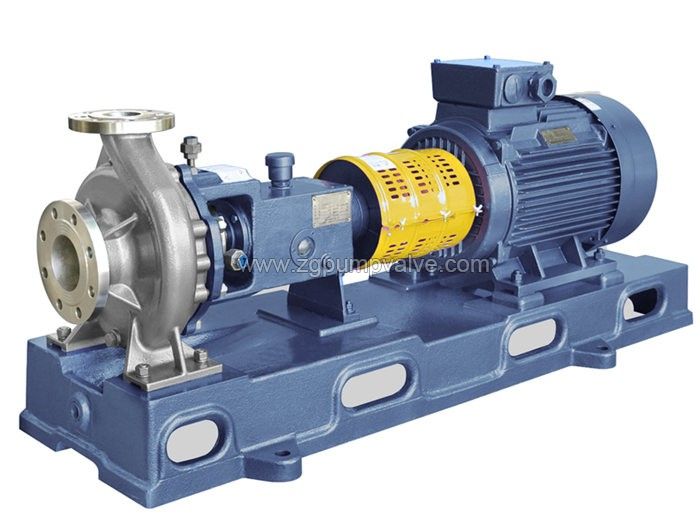

Horizontal chemical process pump

Chemical process pumps are single stage end suction horizontal centrifugal pumps which resist wear, corrosion and high temperature. HZ series are closed impeller, designed to transfer clean or medium containing a small number of particles, easy to crystallize, easy to precipitate. There are various materials available for our centrifugal chemical process pumps, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel…

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

Centrifugal chemical process pumps serve as key equipment in the chemical industry, where those chemical pumps are routinely employed to manage aggressive, toxic, and high-risk fluids. Applications include chemical transfer, acid recirculation, solvent recovery, and wastewater processing. Their chemical compatibility and reliability render them indispensable across chemical processing plants, petroleum refineries, and pharmaceutical production units.

Flow rate:Q=0.8~2500 (m³/h)

Total head:H=3~300 (m)

Speed:n=1450/2900rpm

Temperature:T=-80~425℃

S.g.:γ≤1.85

Pump diameter:50~350mm

Max. pressure:7.5Mpa

In chemical processing, centrifugal chemical process pumps are a preferred choice for transporting corrosive liquids with high efficiency. Their robust design ensures consistent flow rates even when handling corrosive or hazardous media. Below are the key features of our chemical centrifugal pumps in chemical applications:

■ Closed impellers lead to high efficiency.

■ Pumps with closed impeller are designed to transfer clean or fluid contains particles,easy crystallize,precipitate working conditions.

■ Rear door,no need to disassemble the suction and discharge pipeline during maintenance.

■ Special self-locking impeller nut,to eliminate the risk of release.

■ Thickened heavy duty shaft, lengthen bearing space to improve the operation stability.

■ Compound bearing protector.

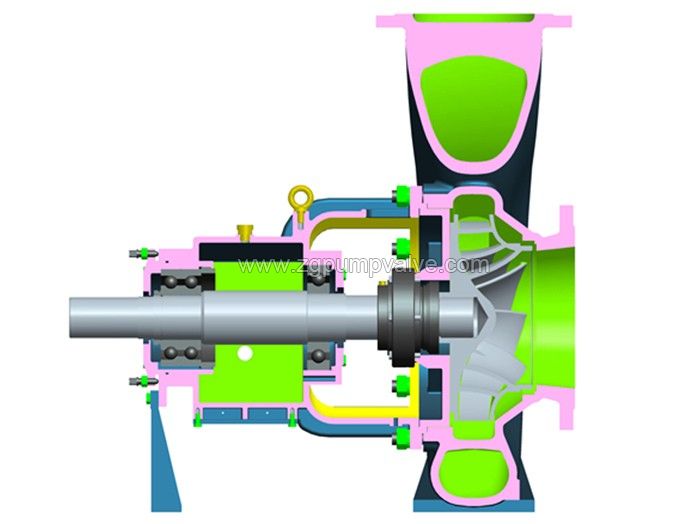

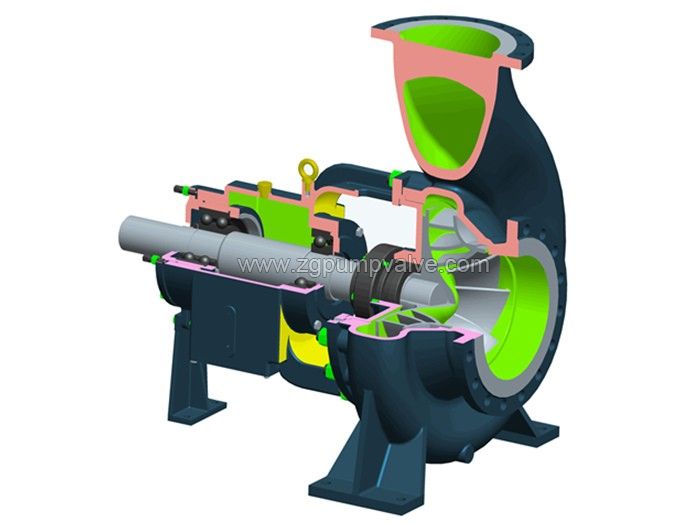

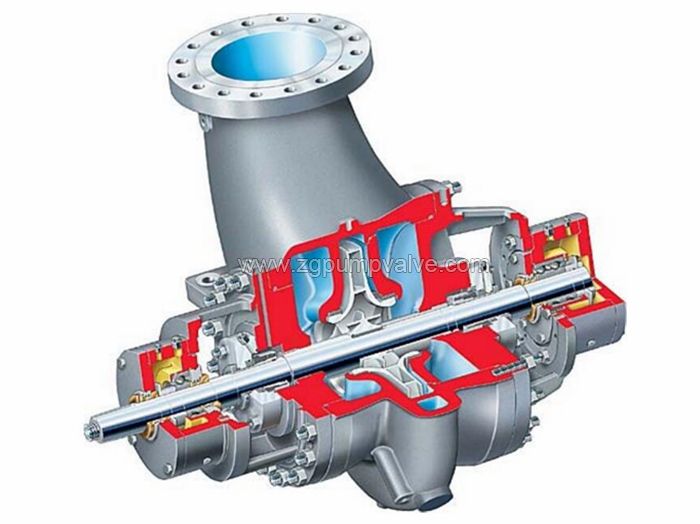

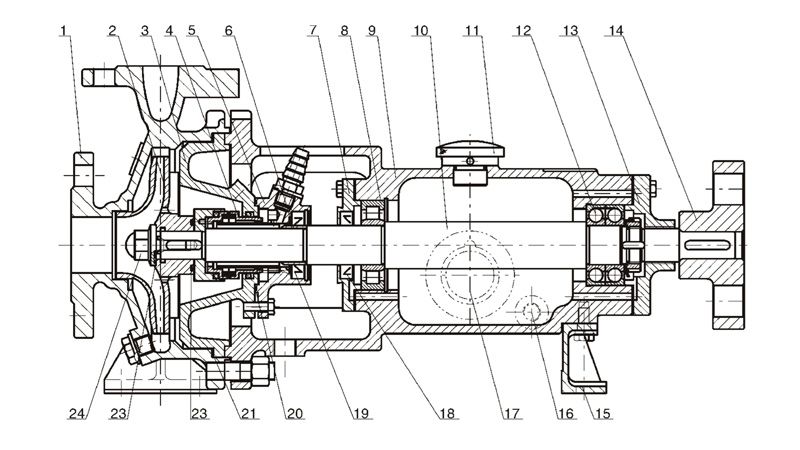

Centrifugal chemical process pumps mainly consist of three main sections: the wetted part, power end, and shaft sealing system. Below are the breakdowns of each part of such chemical centrifugal pumps:

■ The Pump body adopts axial suction, radial discharge and foot support Type, which is directly fixed on the base.It is a chemical centrifugal pump of horizontal,single stage,end suction,cantilever design.It is also called single stage end suction back pull type chemical process pump.

■ Straight cone suction chamber, uniform speed field, small hydraulic loss, suction chamber with guide plate, reduce liquid flow circumferential spin, reduce head loss, improve efficiency

■ Large pump adopts double volute design, reduce radial force,abrasion resistant, pump vibration is small, smooth operation.

■ Optimized impeller design, there are open, semi-open, closed impeller optional, wide applicability of conveying medium

■ Impeller back blade design, reduce the axial force, keep the solid phase away from the machine sealing cavity, improve the service life of the machine sealing.

The pump structure is as follows

1.Pump casing 2.Impeller 3.Pump cover 4.Mechanical seal 5.Seal end gland 6.Wear sleeve 7.Front bearing gland8.Front bearing | 9. Bearing housing 10. Shaft 11. Air vent cover 12. Back bearing 13. Back bearing gland 14. Pump coupling 15. Bracket 16.Pipe plug | 17. Oil-analysis standard 18. Skeleton oil seal 19. Skeleton oil seal 20. O ring of seal end gland 21. Pump cover washer/O ring 22. O ring of impeller 23. O ring of impeller nut 24. Impeller nut |

Chemical process centrifugal pumps are normally made from different materials to withstand corrosive, abrasive, and even hazardous fluids. Common metallic materials for those corrosion resistant centrifugal pumps including austenitic stainless steels (304/316), duplex/super duplex steels (2205/2507), nickel alloys (Hastelloy C276, Alloy 20), and titanium for highly corrosive services. Non-metallic materials like PP, PVDF, FEP linings are adoptd to handle aggressive acids and solvents at temperatures, but PFA lining pumps are able to handle high temperature acids or alkali solutions.

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

Material of construction:

Pump casing: Cast iron/ Carbon steel /Stainless steel SS304/ SS316/ SS316L /Duplex stainless steel 2205 2507 CD4MCu 904L / Titanium / Nickel / Hastelloy /Monel...

Impeller: Cast iron/ Carbon steel /Stainless steel SS304/ SS316/ SS316L /Duplex stainless steel 2205 2507 CD4MCu 904L / Titanium / Nickel / Hastelloy /Monel...

Centrifugal chemical process pumps typically feature a horizontal, end-suction design with back pull-out capability for easy maintenance. However, due to the high customizable features, we have quite different configuration for our chemical centrifugal pumps as below:

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

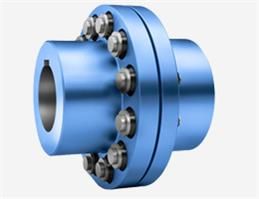

| Couplings |  | Pin type | Flexible diaphragm coupling |

Our Chemical process pumps are widely used for transferring corrosive, toxic, or high-purity fluids in industries like petrochemical, pharmaceutical, and wastewater treatment. Those corrosive resistant chemical centrifugal pumps are able to handle acids, alkalis, solvents, and abrasive slurries in processes including dosing, circulation, filtration, and reactor feeding.

■ Alkali and inorganic salts

■ Strong Alkali/Strong Caustic Soda

■ Metallurgy

■ Iron and steel industry

■ Acid industry

■ Petrochemical

■ Fertilizer

■ Fermentation

■ Environment protection

FAQs of Chemical Process Pumps

1. What Is a Chemical Pump?

A chemical process pump is a particularly designed centrifugal pump for conveying various hazardous chemicals solutions of corrosive, flammable and explosive characteristics. Thus, those chemical pumps are widely used in industries including chemical plants, oil and gas sections, agrochemical plants, lithium battery, water treatment...

2. What Is the Working Principle of Chemical Pumps?

There are various types of chemical pumps, but basically most of them are coupled with a motor to generate the pressure to push the fluid out of discharge nozzle from a pump casing or a pump body. Those chemical pumps are specialized for transportation of hazardous chemical solutions in a safe way; Therefore, they are environment-friendly and safety-high compared to general water pumps.

3. What Chemical Solutions Can Chemical Pumps Deal With?

The centrifugal chemical pumps are designed and built for the purpose of transportation of various hazardous fluids, e.g. acids, alkaline, oil, hot water even chlorine gas...Under such circumstance, it is quite important to select the correct pump type as well as the pump material which can resist the strong corrosion, heavy abrasion or high temperature.

4. How to Select the Suitable Chemical Pumps?

The most essential part of choosing the right chemical process pumps is to provide full medium characteristics to your chemical pump suppliers, including medium composition, temperature, density, vapor pressure, solid content condition...They need those specifications for selecting the right pump material for your pumps, as the wrong material selection would cause the failure of your chemical pumps in a short period of time. Furthermore, the required flow rate as well as head is another necessity for selecting the right size of pumps.

5. What Is the Interval of Maintenances of Chemical Process Pumps?

Proper and in time maintenance is the precondition of smooth running of chemical process pumps. The interval of maintenance is related to the pump types, configurations, the pumping medium characteristics and the working conditions, e.g. continuous or intermittent. Follow the operational manual or simply consult to your pump suppliers for further assistance.

6. What Safety Measures Must Follow During Operation of a Chemical Pump?

■ Before starting the chemical centrifugal pumps, it is important to confirm the direction of rotation, the wrong direction would cause the loosen of impeller nut and further cause the impeller falling off from the shaft.

■ If the pump mechanical seal requires the external flush water, do confirm the flush water is on before starting the chemical pump.

■ Make sure the coupling guard is well installed before start the pump to avoid any physical injury.

■ Open the discharge valve step by step until the pump reaches at the rated point.

■ During the operation of the centrifugal chemical pumps, it is important to get yourself well protected by the personal protective equipment to avoid potential dangers, and make sure the site is well ventilated during the inspection of pumps.

■ Workers must receive enough training for emergency procedures.

7. What Are the Solutions to the Chemical Pump Failures?

Firstly, the chemical process pump must be stopped immediately at the moment the failures or malfunctions happen.

Secondly, find out the exact failed parts of the chemical pump and check whether there are spare parts in the warehouse. Order the failed parts from your pump supplier if it is not available in your warehouse.

Thirdly, replace the failed parts and start the pump again, before starting the pump, rotate the pump couplings by hand to find out whether the pump shaft is stuck.

Finally, start the repaired chemical pump and observe if any malfunctions are still existed.Contact your pump supplier for further assistance if the failure or malfunctions are not eliminated.

8. Can a Chemical Pump be Used for Conveying High Temperature Fluids?

The chemical centrifugal pumps can be used for transportation of high temperature fluids e.g. hot water and hot oil. However, the proper flush plans must be adopted to reduce the temperature of mechanical seal and bearings during the operation of pump. Furthermore, to resist the thermal expansion, the centerline mounted type pump casing must be used if the fluid temperature is up to 302 °F (150 °C).

9. What is the Exceptional Service Life of Chemical Pumps?

Not like general centrifugal water pumps, the service life of chemical pumps is relatively longer due to their robust design and materials. However, it is important to consider the other conditions including the type of chemical pumps, the characteristics of pumping mediums, maintenance conditions...With proper and in time maintenances, the exceptional service life of a chemical pump is supposed to more than five years without replacing essential parts.

10. Are the Chemical Pumps Food Grade and Can be Used for Food Industries?

No, the chemical pumps are not food grade even if their wetted parts are made from stainless steel 316L, as their O-rings, gaskets as well as lubricant oils are not food grade.

11. What Are the Safety Rules of Disposal of Chemical Pumps?

Before disposing the chemical process pumps, it is extremely crucial to understand what mediums they used to handle, and make sure the residual materials in the pump are well neutralized to avoid any pollution to the environment. Consult to your local environment department to receive the local regulations before formally dispose the chemical pumps.

12. Is the Purchasing Cost of Chemical Process Pumps?

Basically, the purchasing cost of chemical pumps has something to do with the pump sizes, pump types, material of construction and other configurations. But there would be big price differences among the pump manufacturers all over the world. Generally, the prices of pump manufacturers from Western countries are much higher. It is recommended to compare the purchasing costs with the same configurations and same level manufacturers of chemical process pumps.

![]() horizontal-chemical-process-pump-catalog.pdf

horizontal-chemical-process-pump-catalog.pdf

Company video

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

+86 28 8218 1182

-

+86 28 8218 1182