Learn - Aug. 05, 2023

In this coal-to-liquids project, the purification system is designed to be three sets of low-temperature methanol washing devices, each set is equipped with three lean methanol liquid pumps, two for operation and one for standby, a total of nine main wash pumps, also known as axially split casing multistage pumps. A lean methanol liquid pump is an important equipment in low-temperature methanol process, which is responsible for the transportation of lean methanol in washing raw gas. This batch of lean methanol pumps belong to BB3 type, while have five stage impellers with a flushing scheme of plan11+52, in accordance with API682 standards.

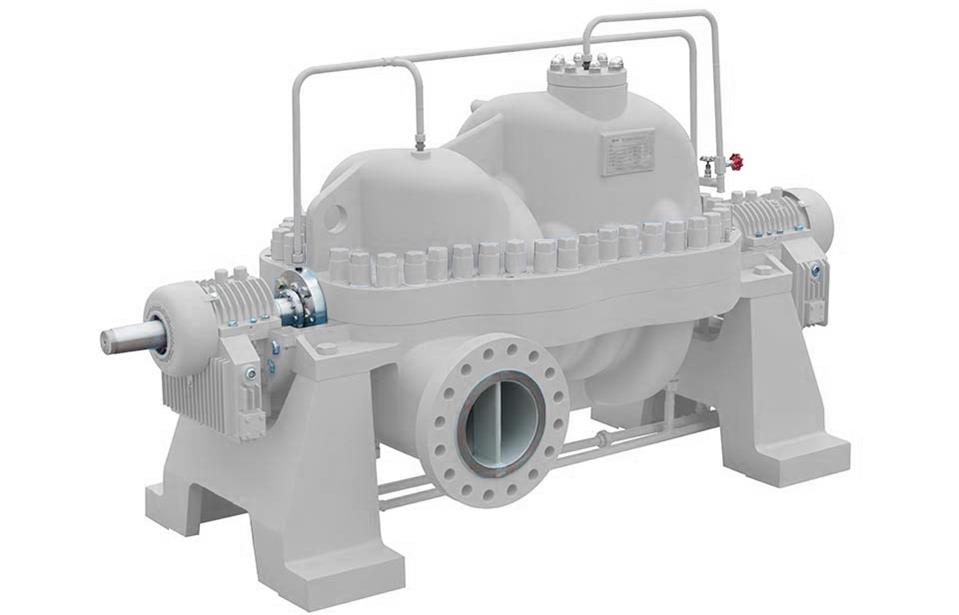

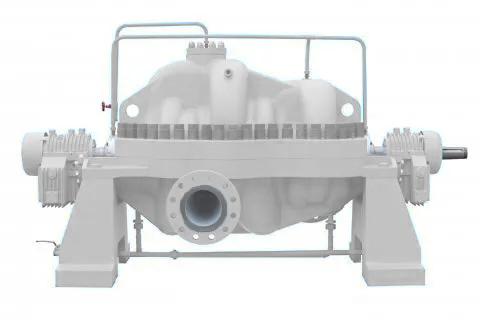

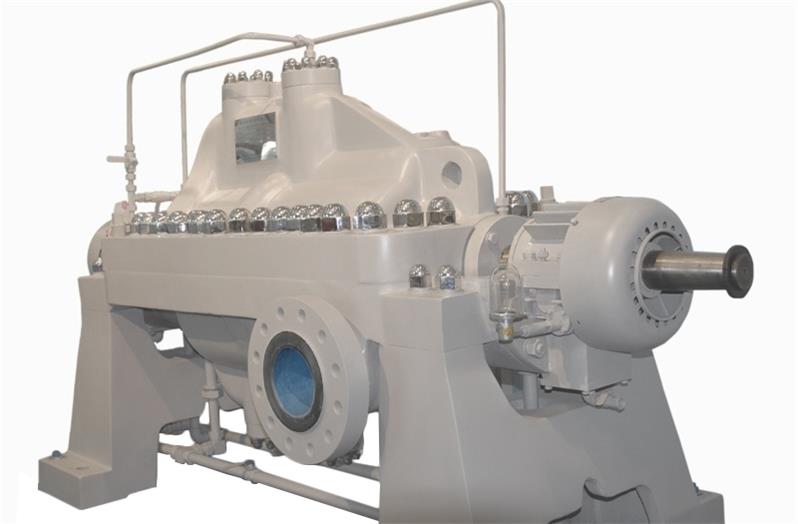

This batch of BB3 lean methanol liquid pump is a multistage centrifugal pump with double volute, axial split, horizontal center line support, and back-to-back symmetrical impeller arrangement. Due to the back-to-back symmetrical arrangement of the impeller and the double volute structure design, most of the axial force and all the radial force of the horizontal multi-stage pump can be automatically balanced, so the pump runs more smoothly and owns a long service life. The first stage impeller is the double suction structure, which is better for NPSHa.

Our engineers attach great importance to the installation and commissioning of this batch of axial split casing multi-stage pumps like every time, while take into account the whole process, solve the problems at any time, and are present for the site when necessary, we all make sure that customers get the best service.

Installation steps are as follows:

1. Locate, align, and level the base Determine the installation reference line and ensure that the base is level in all directions. After leveling the base, tighten the base bolts but do not completely tighten them.

2. First alignment Check the alignment of the coupling, and control the axial and radial deviation of the pump and motor within 0.076mm tolerance.

3. First grouting Use epoxy resin grouting material to grout the reserved anchor bolt holes and ensure that the base does not vibrate during grouting.

4. Horizontal precision and initial accurate alignment The pump pipe mouth is horizontal entry and exit, the equipment leveling selects the surface of the lower half shell exposed processing accuracy, and the horizontal deviation is controlled within the range of 0.02-1000.

5. Secondary grouting Grouting between the base of the mechanical equipment and the foundation through the round hole on the upper part of the base. Then tighten the foundation bolts completely.

6. Accurate alignment Each part of the pump is bolted, and the motor is adjusted according to the pump. Coupling alignment requires that the axial end deviation is less than 0.025mm, and the radial alignment deviation is less than 0.05mm. Operating equipment should strive to achieve accurate alignment to minimize the shaft, bearing, coupling force on the pump caused by additional wear, noise, vibration, resulting in shortened service life. More about pump pairs, click to view (link pairs).

7. Pipe installation The suction pipe should be short and straight, and the suction pipe should be twice the diameter of the pump inlet. Make a good support for the external pipe to avoid excessive load on the pump pipe mouth.

8. Check and ensure the pipeline without stress Install a dial indicator on the coupling to monitor the axial and radial conditions of the horizontal multistage pump with a deviation of less than 0. 05 mm.

This batch of pumps were installed in the shortest possible time with the efforts of engineers from factory and us. The first test run of nine lean methanol liquid pumps was successful, and the operating data and performance of pumps reached the expected level. After one year of operation axially split casing multi-stage pumps, they run smoothly without unplanned downtime and maintenance. Our axially split multistage pumps and professional service earn customers' trust and satisfaction.

We are not just the manufacturer of high quality pumps, not just striving in the order-related business efforts, but always concern about the series of after-sales service for customers, including pumps installation, maintenance, upgrade and improvement. We like listening to the pump's comments from end users. We are always passionate about fluid and solution challenges.

The pump housing of an axially split dual volute multistage pump is separated horizontally on the axis line, the upper part is the pump cover, the lower part is the pump body, and the suction inlet and outlet are on the pump body under the pump axis, all in the horizontal direction. The characteristics is symmetrical arrangement of impellers, automatic balance of axial thrust, no complex balancing device, simple structure, and long service life. Bearings adopt the cooling fans, and the two ends of the bearing are equipped with cooling devices, so the heat dissipation effect is better.