Learn - Jul. 29, 2025

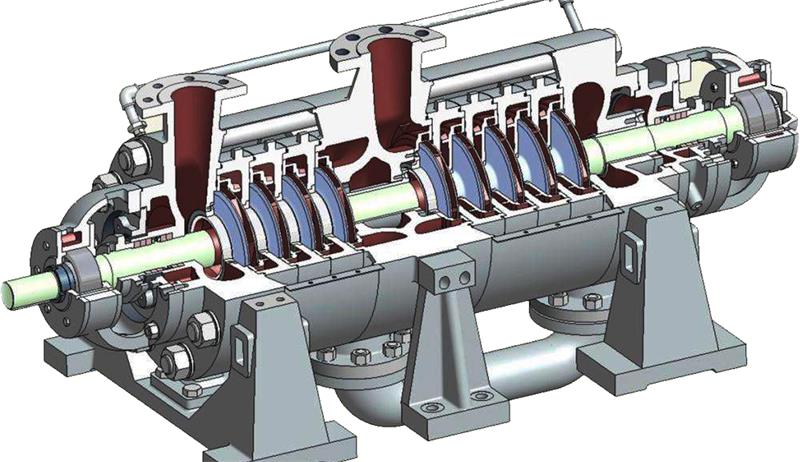

Basically, a multistage pump is a pumping device with at least two impellers rotating synchronously in the same pump shaft. These impellers can be the same type with same diameter, but there are different types of impellers for such multistage pumps, including double-suction impeller, low NPSHr impeller, self-balancing impeller or even a mix of centrifugal and side-channel designs.

The advantage of this design enables each impeller to boost the pressure at each stage, and eventually the high pressure can be generated at the end of the pump stage, in this way, the high pump discharge pressure can be formed at the pump discharge nozzle.

The diversified impeller designs allow the multi-stage pumps to work as booster pumps in boiler feed systems, reverse osmosis or industrial cleaning, their adaptable design making them the ideal pumping device for most of the high-pressure requirements, and the typically usage of multi-stage pumps are working as the boiler feed water pumps in various boiler systems.

Multistage pumps share most of their parts with regular end suction centrifugal pumps, but there are a few key differences. In multistage centrifugal pumps, there are extra components called diffusers, which help to guide the fluid smoothly into the next impeller or stage. For side channel pumps, there are intermediate plates with specially shaped (scalloped) channels that help to move the liquid through the system.

Because that the impellers of a multi-stage pump are assembled into the same direction, then a lot of thrust force will be created. Thus, such pumps require a special balancing device - either a balance disc or balance drum to reduce the thrust down to a level that regular bearings can handle. However, the self-balancing multistage pumps are an exception which does not require any balancing device at all.

Multistage pumps function by setting up a series of impellers rotating on the same shaft, with each impeller feeding the fluid and pressure into the next stage. The quantity and type of impellers are determined by the required capacity-both flow rate and discharge pressure. Generally, the higher the required pressure is, the more impellers there will be.

Firstly, the fluid enters the pump casing through the suction nozzle, then it will be pushed through each stage of impeller by the pressure generated by the rotating impellers. The optimized hydraulic models of multistage centrifugal pumps guide the fluid smoothly from the first stage all the way to the final discharge point, usually the first stage is on the left of the pump. The direction of pump suction and discharge can be customized, but normally the nozzle direction of boiler feed water pumps is supposed to be upwards.

While keeping the feature of high pump efficiency, the multi-stage design allows the multistage centrifugal pumps to create much higher pressures compared to regular single stage end suction centrifugal pumps. The specific design allows for customization - engineers can specify the exact number of stages and configuration to meet the required pressure. This adaptability makes multistage pumps an ideal solution for most of the high pressure required applications.

Because of the high-pressure feature, the Multistage centrifugal high-pressure pumps can be easily found among the multiple industries. Due to their ability of high-pressure, they are suitable for pumping water to the upper floors of skyscrapers, supplying feedwater to the industrial boilers, creating necessary pressure to push water through membranes for reverse osmosis (RO) systems in water treatment plants.

The highly adaptable multistage pumps are also doing a good job in cleaning application, where they create the high-pressure jets for industrial washing purposes. They are also quite important for transportation of fuel in both traditional and renewable power generation plants. The production process of oil and gas industry requires such centrifugal multistage pumps as well, and in minging industry, they handle various tough high-pressure fluid jobs.

The most outstanding feature of multistage centrifugal pumps is that they can well handle both high pressure and high temperature, while pumping high temperature fluids over 100 degrees Celsius, the flush plan P21 is recommended, and the mounting of pump casings must be switched to centerline mounted from foot mounted. Due to this two-in-one capability, they are widely adopted for heating systems, boiler systems, condensate recovery and other tough jobs which requires both high discharge head as well as high temperature resistance.

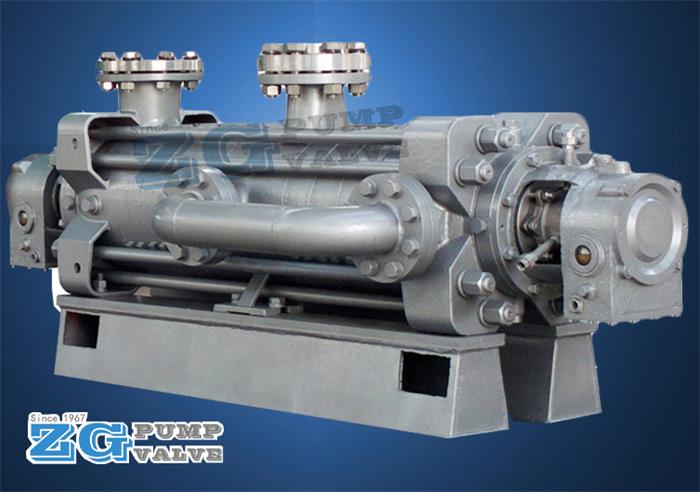

● Horizontal Multistage Pump (most widely used)

● Vertical Multistage Pump (typically for restricted spaces)

● Submersible Sump Type Multistage Pump (vertical type)

● Side Channel Multistage Pump (end suction type)

● Horizontal Split Case Multistage Pump

● Vertical Turbine Pump (multi-stage type)

● Special Material Multistage pump (e.g. Titanium, Nickel, Monel...)

When comparing a centrifugal multistage pump to a standard centrifugal pump, the multistage option is though more complex and expensive—typically offers superior hydraulic performance, higher pump efficiency, and the enhanced reliability. Due to its optimized hydraulic models, the flexibility to add impeller numbers, and the ability to trim them for precise adjustments, the multistage pumps can well match the required rated point without scarifying other parameters. This means the pump is more likely to work near its Best Efficiency Point (BEP), ensuring both efficient and reliable performance.

Multistage pumps are able to be designed with an interstage bleed-off feature when multiple duty points are needed. Another advantage is they can often work at lower speeds compared to single-stage centrifugal pumps. While this may improve efficiency in some cases, another noticeable benefit is significantly quieter operation – a key factor in today's noise-sensitive environments. Keep in mind that just a 3 dBA increase actually doubles the perceived sound level.

The most outstanding difference is the number of impellers. A single stage end suction centrifugal pump requires only one impeller, while the horizontal multi-stage centrifugal pump can be installed more than two impellers based on the customized pump capacity.

Some additional pump parts are required in a multistage pump, like diffusers, thrust balancing devices (balancing disc or balancing drum), dual sealing systems...

Another important difference is the pump casing configuration, the multistage centrifugal pumps adopt segmented casings, either ring-section type or barrel type, while the single stage pumps use the volute casings.

The pump shaft and bearing designs are also different between two pump types. The multi-stage pumps typically have longer and robust shaft to assemble more impellers on itself, due to this feature, the bearings must be heavy duty types to handle the extra loads. On the other hand, the single stage pumps normally have a shorter shaft which is only fit for one impeller, thus the bearings can be standard types.

Reading the curves of a multistage pump should follow the same way as checking the performance curves of other standard centrifugal pumps. However, it is important to be aware that some pump manufacturers provide curves of only one stage, which means the values in the curves must be multiplied by the number of pump stages. One critical distinction must be noted: just the opposite performance with centrifugal pumps, the side channel multistage pumps reach the maximum power consumption at the zero-flow rate, and the power consumption decreasing as the flow rate increases.

● The shaft arrangement of pump, vertical or horizontal.

● The vertical multistage centrifugal pumps are designed and built for dry installation on the ground, making them suitable for applications with restricted space. However, a key maintenance requirement is to disassemble the motor before any maintenance can be carried out.

● Vertical long shaft multi-stage pumps are employed in applications where the motor must be lifted from the sump or tank to manage the maintenance job. A common feature in such vertical pumps is the motor bears the thrust load-such as in VTP turbine pumps, where the bearings of electric motors are specifically designed for this purpose. This design eliminates the necessity of a set of thrust bearings for the pump, therefore simplifies the structure of pump and reduces the pump cost.

● Most of the horizontal multi-stage centrifugal pumps are typically foot-mounted, but for high-temperature applications, it requires centerline mounted to resist the thermal expansion. This design can prevent operational issues caused by thermal growth and contraction. Proper alignment with the electric motor is important for such horizontal type of multistage pump. On the other hand, vertical multistage pumps (such as sump pumps) require a simpler mounting system. A supporting base plate is secured by using standard bolting, and since the motor is flange-mounted with a self-aligning ability, no additional alignment is typically necessary.

The most widely used multistage pumps in various industrial applications are horizontal and vertically mounted (dry-installed) types. Additionally, side channel multistage pumps and vertical turbine pumps with multi-impellers are also commonly employed.

Multistage centrifugal pumps work as the essential pumping devices among multiple industries, providing the function of critical fluid transfer and pressure boosting. Their customizable design enables those pumps to be suitable for diverse applications including municipal water supply, agricultural irrigation, chemical processing, petrochemical processing and power plants. The following contents provides a comprehensive analysis of centrifugal multistage pumps, with both their operational advantages and inherent restrictions.

Higher Efficiency: The multistage centrifugal pumps are widely used because of their reliable performance and high efficiency. While maintaining the high efficiency, they can create high pressure for various applications by adopting a series of impellers rotating in the same pump shaft. In this way, they are able to transfer the fluids efficiently to far away places with comparatively lower power consumption, thus can reduce the cost sharply during the operation.

Versatility: The multi-stage centrifugal pumps can be highly customized, so they are suitable for diverse applications. They are widely used in boiler feed systems, long distance transportations, booster systems, mining and other industrial processes. The capability of managing different fluids and pressure requirements enables those pumps to be the important pumping devices across multiple industries.

High-Pressure Capability: A key advantage of multi-stage pumps is their ability to create substantial pressure based on needs. They are able to lift the fluids to the required levels efficiently, making them indispensable for high-pressure applications including oil and gas, chemical processing, and power generation where frequently require multistage pumps to compensate for low-pressure supply systems.

Superior Reliability: The centrifugal type of multistage pumps is designed for dependable performance. The robust construction and high-quality materials of such pumps ensure exceptional durability, minimizing wear and tear during the operation. This enhanced reliability translates to extended service life, reduced maintenance requirements, and lower operational costs through decreased downtime.

Space Saving: The multistage centrifugal water pumps take much less spaces compared to the single stage pumps at the same flow rate or same discharge pressure. Their compact but powerful design making them to be able to create high discharge pressure without requiring excessive space on the ground, it is a critical benefit for space-constrained places like offshore platforms or compact industrial plants like small skid-mounted systems.

Better Cavitation Resistance: A critical advantage of such multistage water pumps is their inherent ability of resistance to cavitation - a destructive phenomenon in fluid transportation systems where sudden pressure drops cause vapor bubble formation and implosion. Unlike the general single stage water pumps, multistage pumps improve this problem by optimizing pressure distribution in the multiple stages. This design enables them to be particularly suitable for demanding applications of fluctuating pressure conditions, thus realize the longevity and consistent stable performance.

Purchasing Cost: The higher upfront purchasing cost is the biggest disadvantage of multi-stage pumps. Compared to single stage centrifugal pumps at the similar capacities, the multistage types are normally more expensive because of they require more raw materials, sealing systems as well as longer production time. Despite of this disadvantage, the multi-stage centrifugal pumps can make up the initial cost by the stable and highly efficient long-time operation in the future.

Difficulty In Maintenance: The multistage type of centrifugal pumps are proven to be highly reliable, but obviously their maintenance tends to be more involved than single stage centrifugal pumps. It is mainly because that the multiple impellers, stages and mechanical seals always require special tools as well as professional engineers during the operation and maintenance. In order to keep the optimal efficient operation and stable performance, more time and personnels must be involved.

Higher Power Consumption at Less Flow: The Multi-stage pumps are supposed to work at peak efficiency when operating at their rated flow rate and head. However, their performance may decline under the condition of partial flow rate caused by the VFD control of motors, particularly in systems where the variable flow rates are required. The partial flow rate can cause higher power consumption as well as the lower pump efficiency. By implementing the optimized system design and advanced control strategies may help to deal with this potential challenge.

Higher Noises & Vibration Values: The multistage pumps may generate higher noises and vibration values due to the design of multiple impellers and stages, this is an obvious disadvantage for applications where the lower decibel environment is required. However, some additional noise covering methods like a silencing canopy can be used to reduce the noise level.

Limited Capability for Low Head Applications: The multistage centrifugal pumps are known as high pressure booster pumps, obviously they are not suitable for applications where the low discharge head is required. On the other hand, the single stage end suction centrifugal pumps are a better choice for scenarios that only require low or moderate discharge head.

It is believed that by going though of this article, you would have a clear understanding of various types of multistage pumps, which are the ideal choice for transportation of fluids in an efficient way. They have some obvious advantages as well as disadvantages, which means you have to evaluate your real needs before you can select the right pump models. Please keep in mind, sometimes the long-term interests must also be considered in your budget, focusing only on the initial cost does not mean it is the right way of saving money.

However, you are always welcome to contact us for any further questions or inquires, as a professional multistage pump manufacturer with decades experiences, we provide 7x24 online services and guidance to our clients all over the world.

Contact us now: sales@zgpumpvalve.com or wa.me(Whatsapp: +8613738006567)

Visit our workshops by VR Tour