Learn - Dec. 02, 2022

A vertical axial flow pump is a large vertical pump device composed of inlet channel, impeller, guide vane and outlet channel, used for conveying large flow, low head liquid, widely used in agricultural drainage and irrigation, hydraulic engineering, power plant, salt plant, chemical industry and other industries.

The vertical axial flow pump is the typical single-stage, guide vane pump with high efficiency, large flow, low head and good cavitation resistance. The pump is installed vertically, covers a small area, the blade is adjustable, the performance parameters are adjustable, and is suitable for low water level conditions, the application range is very wide.

Pump operation process, that is, the water in the pool, through the suction bell, due to the rotation of the impeller, lead the water into the guide vane body, flows through the elbow, discharged from the outlet pipe.

The vertical axial flow pump is connected with the middle joint pipe through a rigid coupling, and the bearing under the motor support bears all the downward axial force of the rotor. The intermediate shaft is connected with the motor shaft by an elastic coupling.

The vertical axial flow pump is based on the lift theory of the wing in aerodynamics. When the fluid bypassing the airfoil, it separates into two streams at the head end of the airfoil, which pass through the upper surface and the lower surface respectively, and then converge at the tail end of the airfoil at the same time. As the flow velocity along the lower surface of the airfoil is longer than that along the upper surface, the flow velocity along the lower surface of the airfoil is larger than that along the upper surface, correspondingly, the pressure on the lower surface of the airfoil is smaller than that on the upper surface. In the same way that the fluid exerts a downward force on the airfoil, the airfoil exerts an equal and opposite force on the fluid, and the water is pressed up to a certain height.

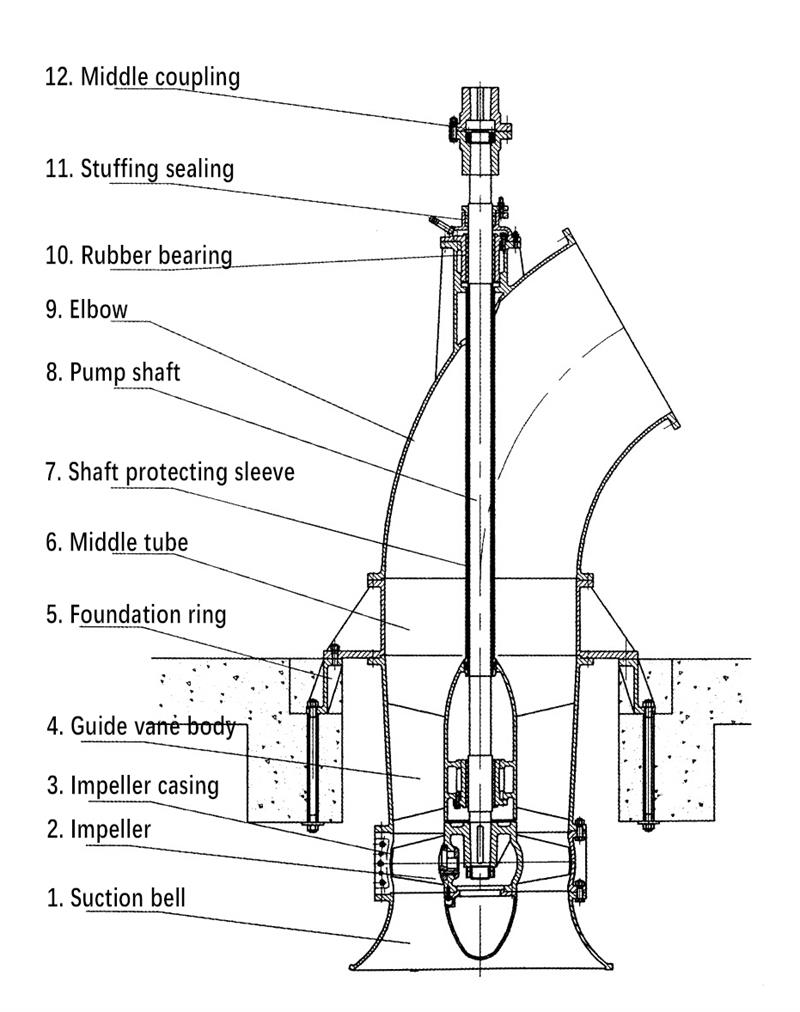

| 1.Suction bell | 2.Impeller | 3.Impeller casing | 4.Guide vane body | 5.Foundation ring | 6.Middle tube |

| 7.Shaft protecting sleeve | 8.Pump shaft | 9. Elbow | 10.Bearing | 11.Stuffing sealing | 12.Middle coupling |

Main parts of a vertical axial flow pump:

Suction pipe: The suction pipe of medium and small-sized vertical axial flow pump often adopts suction bell; while large-sized vertical axial flow pumps often adopt elbow or bell type suction channel, which guide the water to the impeller with minimum loss.

Impeller: The impeller is the main working part of vertical axial flow pump, which is composed of blade, hub, water guide cone, etc.

Guide vane: the guide vane is located above the impeller, and its main function is to eliminate the rotational movement of water flow and reduce the head loss. At the same time, part of the kinetic energy of the flow can be converted into pressure energy.

Pump shaft: Transmit torque to the impeller of vertical axial flow pump

Bearings: Reduce the friction coefficient of the pump shaft during rotation

Middle coupling: The connecting part between the vertical axial flow pump and the motor, which transmits the motor power to the pump

Packing box: A packing sealing device is installed where the pump shaft passes through the outlet elbow.

Compared with centrifugal pump, vertical axial flow pump has the following advantages:

4.1 The head increases sharply with the decrease of flow, and the Q-H curve increases gradually. The main reason is that when the flow is small, backflow occurs at the inlet and outlet of the impeller blade, and the water flow gets energy repeatedly, similar to the multistage pressurization state. Therefore, the head increases sharply, resulting in an increase in the axial power.

4.2. The Q-N curve is a step-down curve. Therefore, when the axial flow pump is started, the motor should be started when the gate valve is fully opened.

4.3 Q- η The curve is in the shape of a hump. That is, the range of high efficiency is very small, and the efficiency will drop quickly when the flow is not far away from the design working point. According to this characteristic of axial flow pump, it is unfavorable to adopt gate valve to regulate the flow. Generally, only the method of changing the blade device angle can be adopted to change its performance curve.

4.4 Among the pump samples, the NPSH of axial flow pump is generally required to be large, so the maximum allowable suction vacuum height is small. It is necessary to consider the water inlet conditions of axial flow pump, the deviation degree between the actual operating point and the design operating point of the pump.

5.1 The causes and treatment methods of no water or little water after startup are as follows:

● The submergence depth of impeller is not enough. The treatment is to adjust the submergence depth of the impeller.

● The impeller steering is wrong. The treatment is to adjust the motor steering.

● The blade is damaged or the blade positioning pin is broken. The treatment is to replace the blade or positioning pin.

● The pump inlet or impeller is blocked by debris. The way to deal with it is to remove debris.

● The pump shaft falls off. The treatment is to reassemble or replace the pump shaft.

5.2 The causes and treatment methods of large vibration or noise are as follows:

● The anchor bolt is loose. The treatment method is to tighten the anchor bolts and pad the base firmly.

● The pump shaft is bent or the coupling is not concentric. The treatment is to correct or adjust the concentricity.

● The pump shaft or water guide bearing is worn. The treatment is to replace water guide bearing or pump shaft.

● The blade is damaged or wrapped with debris. The treatment is to replace the blade and remove the debris from the blade.

● Cavitation occurs. The treatment method is to improve water absorption conditions to prevent cavitation.

● The coupling breaks or falls off. The treatment is to replace the coupling.

● The bearing in the bearing box is damaged. The treatment method is to replace the bearing.

5.3 The causes and treatment methods of sudden increase or low current are as follows:

● Loss corner faults of blade. Or the blades are tangled in debris. The treatment is to replace the blade and remove the debris.

● The water guide bearing is corrode. The treatment is to replace the water guide bearing.

● The pump shaft or coupling falls off or breaks. The treatment is to replace the pump shaft or coupling.

● The impeller shell falls off. The treatment is to replace the impeller housing.

● The opening degree of water outlet flap is too small. The handling method is to check the shutter pin shaft and add lubricating grease.

● The impeller falls off. The treatment is to replace the impeller.

5.4 The temperature of bearing housing is too high

● Serious lack of lubricating oil. The treatment is to add lubricating oil.

● Severe wear and tear occurs. The solution is to find the cause and replace the parts.

● Agricultural drainage and irrigation

● Water supply and drainage of power station

● City flood prevention

● City water supply

● Water supply and drainage of docks

● Thermoelectricity station circulating water transferring

● Dock water level rising and lowering

● Aquaculture

● Saltworks draw water