Learn - Jul. 20, 2023

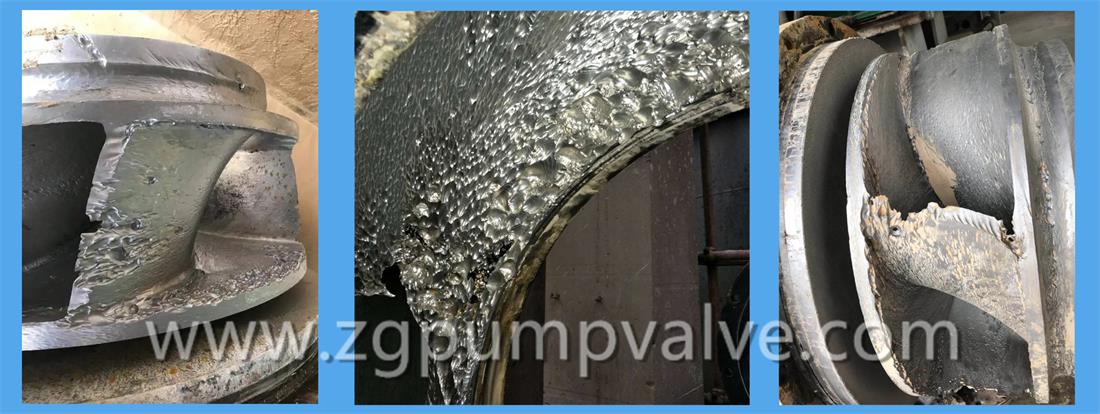

The wet flue gas desulfurization technology is the most commonly used in thermal power plants. The desulfurization recirculating pump is one of the key equipment of the limestone-gypsum wet desulphurization unit, which transmits limestone-gypsum solution. This medium is highly corrosive and abrasive. Usually mixed flow desulfurization pumps made from metal materials are used in thermal power plants, but those pumps often suffers from wear in short time, and even serious wear leads to downtime. Customers are eager to find a kind of corrosion and wear resistant desulfurization pump, which is exactly what we are good at manufacturing corrosion and wear resistant silicon carbide ceramic lined desulfurization pump.

The design feature of ceramic recirculating pump is: based on the high efficiency hydraulic model of metal horizontal mixed flow pump, combined with ceramic-metal composite manufacturing technology, manufacture a high-efficiency desulphurization pump with corrosion resistance and wear resistance. The flow parts of the ceramic lined mixed flow pump, including the inner surface of the pump housing, the inner surface of the pump cover, and the impeller, are lined with silicon carbide ceramics. The ceramic material is a special ingredient and process of non-pressure sintered silicon carbide, which ensures that the metal shell and the ceramic lining are integrated, and the lifetime of the ceramic lined desulfurization pump is long. The silicon carbide lining manufactured by vacuum process is tightly combined with the metal skeleton and the pump operates smoothly for a long time.

Silicon carbide is sintered in liquid phase. The relative density of SiC ceramics sintered in liquid phase increases from 98% to 99% and is almost completely dense. The strength of the material is increased from 600MPa to 707MPa, and the fracture toughness is increased from 8.1 MPa.m1/2 to 10.7 MPa.m1/2. Non-pressure liquid phase sintering of SiC ceramics is especially suitable for use in high performance requirements. Silicon carbide could withstand abrasion of particles with higher density, which could thoroughly solve the abrasion problem of solid-liquid two-phase flow mixed desulphurization pump.

| Item | Unit | Data |

| Density | g/cm3 | 2.5 |

| Hardness | HBV | 920 |

| Tensile strength | MPa | >20 |

| Elastic modulus | GPa | >30 |

| Compressive strength | MPa | >250 |

| Flexural strength | MPa | >50 |

| Glass transition | ℃ | >210 |

| Thermal conductivity | W/m.k | 1.5 |

Pump body: the shell of the pump body is made of high-strength ductile cast iron, and the flow parts are all silicon carbide ceramic composite materials. Silicon carbide surface finish is high, and pumps have high hydraulic efficiency high;

Impeller: The impeller consists of a metal impeller skeleton + silicon carbide ceramic composite material. The overall rigidity of the composite impeller is strong, and it can withstand the impact and erosion of solid particles. The hydraulic model of the impeller is good, the surface of the blade is smooth, and the hydraulic efficiency of the impeller is high.

The combination of metal skeleton and silicon carbide ceramic composite materials adopts a special design method, which is to make the combination of metal and lining part stronger, and the minimum thickness of the lining part reaches 15mm, in order to achieve excellent performance of impact resistance and abrasion resistance and corrosion resistance.

The Silicon Carbide Ceramic lined mixed flow pump is the most advanced technology, but also the most ideal desulfurization pump, it has excellent corrosion resistance and wear resistance with smooth flow channel with excellent hydraulic model. The flow parts of the desulfurization pump adopt the structure of metal skeleton lined silicon carbide composite ceramic material, which is suitable for any medium with PH value 1 ~ 14, and is not limited by the concentration of chloride and fluoride in the slurry, and has strong corrosion resistance.

Silicon carbide material has a very high hardness, strong flexibility and crack resistance, also has a very strong wear resistance, chemical corrosion resistance and oxidation resistance.

Learn more about mixed flow pump.

The above information is provided by the ceramic desulfurization pump manufacturer.