Learn - Oct. 13, 2022

The Evaporator Circulation Pump, is also known as Horizontal Axial Flow Pump, Elbow Pump, Forced Circulation Pump, is the key equipment in the chlor-alkali industry.

Chlor-alkali industry and soda industry are important components of basic chemical industry. Caustic soda and chlorine gas produced from aqueous solution of electrolytic salt are basic chemical raw materials. About 80% of the chlor-alkali industry uses diaphragm membrane process, 20% is the ionic membrane process(ion-exchange membrane process). The diaphragm membrane caustic soda evaporation is characterized by sodium chloride crystal precipitation in the evaporation process, for this concentration of crystal precipitation, the use of forced circulation evaporator. The main components of the forced circulation evaporator system are: gas-distributing cylinder, heater, evaporative separator, condenser (mixed or surface type), forced circulation pump, all kinds of liquid conveying pump, vacuum pump, condensate pump, operation platform, electrical instrument control cabinet and boundary pipe valve, etc. The important equipment of forced circulation evaporation process is evaporation circulation pump, which is the horizontal axial flow forced circulation pump.

Nowadays, the evaporative circulating pump used in chlor-alkali industry is the fifth generation of evaporative circulating pump, which adopts axial flow structure. Large diameter evaporative circulating pumps are all suspended structure, as shown in Figure 1. Pump manufacturers can supply suspended or spring-supported evaporative circulation pumps to remove the waveform expansion joints of the evaporator. In order to adapt to the conditions of high evaporation temperature, the pump body mostly adopts the center support type. Most of the rotor out of the rear door structure, maintenance of mechanical seals do not have to remove the pump inlet and outlet flange, more convenient than the front door.

Considering the special requirements of chlor-alkali evaporation, the medium speed evaporation circulating pump and the slow speed evaporation circulating pump are developed.

A evaporator circulation pump can not be equipped with standby pump, the pump must be continuous operation, such as failure will cause the whole evaporation system to stop, so the safety and reliability of the evaporation circulation pump is particularly important. The main technical characteristics of horizontal axial flow evaporation circulating pump are as follows:

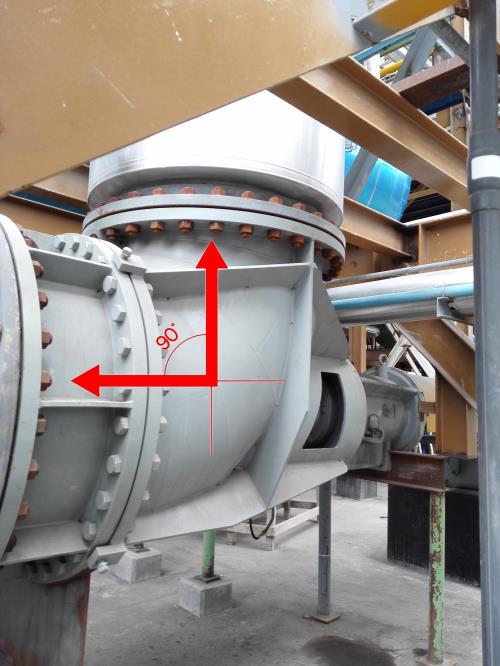

1.Cantilever chemical axial flow pump structure. The evaporative circulation pump uses cantilever axial flow pump structure as the evaporative circulation of chlor-alkali industry. The pump body of cantilever axial flow pump is 90° elbow type, as shown in Figure 2, the number of shaft seal is small, the wet area of flow parts is small, corrosion resistance.

Figure 2

Figure 2

2.The center support of the pump body can avoid the thermal offset between the axis line of the pump body and the axis line of the rotor. Because the evaporation circulation pump in the chlor-alkali industry has a large diameter, the medium temperature is 100 ~ 165℃, and the center support of the pump body is compared with the foot support, which can avoid the thermal offset between the axial line of the pump body and the axis line of the rotor, and the radial clearance between the impeller and the pump body can be smaller, so as to improve the volumetric efficiency of the pump

3.Suspended pump or spring mounted baseplate pump avoids the use of expansion joint, in order to achieve thermal compensation effect.

① Thermal compensation method 1: you can hang the evaporation circulating pump on the evaporator, expand with the evaporator, cancel the expansion joint, eliminate the thermal expansion force acting on the inlet and outlet of the evaporation circulating pump.

② Thermal compensation method 2: the evaporation circulation pump can be installed on the spring support. There is an adjustable spring box below the pump base. The precompression force of the spring and the load on the evaporator support during operation can be artificially adjusted, and the expansion joint can be canceled.

4.Adjust the performance. The high efficiency area of the axial flow evaporation circulation pump is narrow. In order to meet the requirements of different end users with one specification of the product, so that the pump can operate in the high efficiency area, the pump performance parameters should be able to be adjusted. In addition, the operating conditions of the evaporator often change or the pump impeller wear also requires to be able to adjust its performance. The commonly used performance adjustment method is to change the pump speed and impeller blade placement Angle. Pump speed change, can be proportional to the flow rate and speed of the first square, head and speed of the second square is proportional to the shaft power and speed of the third square is proportional to the conversion. For one-off performance changes, different poles (2, 4, 6...) can be replaced. To adjust the motor or replace the reducer. If the operation parameters of the pump need to be changed frequently, the turbine or hydraulic coupling can be used to drive.

When the blade placement Angle changes, the maximum efficiency value of the pump changes very little, and the head of the maximum efficiency point and the rated point change very little. The flow rate can be adjusted using the characteristic curve when the blade placement Angle is changed so that the pump can still operate normally.

When the blade placement Angle is increased, the flow rate and shaft power are increased. The flow rate variation range is related to the specifications of the axial flow evaporation circulating pump and the Angle of attack, which is generally 3%-5%.

Brief introduce the design of evaporative circulating pump

1.Determination of pump speed n

The pump speed is limited by the cavitation performance and the blade tip circumferential speed required by the crystallization process (generally < 20m/s).

Considering the characteristics that the necessary cavitation allowance NPSHR of the axial-flow pump will increase in off-design conditions, NPSHR ≤ NPSHa-1m. According to the axial flow pump cavitation ratio speed calculation pump speed n. When the impeller diameter is determined and then check the tip circumference velocity.

n = C (NPSHR) 4/3 / (5.62Q 1/2)

C -- cavitation ratio speed, generally 800 ~ 950;

Q -- pump design flow rate (unit: m3/s).

2.Determination of impeller outer diameter D and hub diameter dh

Impeller diameter D should be calculated according to the axial surface velocity vm and impeller hub ratio dh/D. Axial surface velocity vm:

vm = (0.06 0.08)3 (Qn2)1/2

Q is the flow rate at the design point of the pump (unit: m3/s).

The hub ratio dh/D of axial-flow pump impeller is related to the specific revolution ns. Table 3 shows the statistical data of the hub ratio dh/D of axial-flow pump.

Table 3 Relationship Between Hub Ratio dh/D & specific speed ns

| ns | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 |

| dh/D | 0.5 ~ 0.63 | 0.46 ~ 0.59 | 0.44 ~ 0.56 | 0.4 ~ 0.53 | 0.37 ~ 0.5 | 0.35 ~ 0.48 | 0.33 ~ 0.46 |

Low specific speed ns axial flow pump impeller blade number is more, but it is designed as a rotary vane type axial flow pump, so the structure requires the hub diameter dh is larger.

Impeller outer diameter D:

D =[4 Q / π vm (1-d2h/D2)]1/2

3.Selection of blade number Z

The blade number Z of axial-flow pump impeller is related to the specific speed ns, and the selection of blade number Z is shown in Table 4.

Table 4 Relationship Between Blade Number & Specific Speed ns

| ns | ≤500 | 500 to 800 | ≥800 |

| Z | 6 | 5 to 4 | 4 to 3 |

4.Determination of leaf thickness y

Maximum blade thickness at hub:

ymax =(0.012-0.015) KD (1.5 H)1/2

D -- impeller outer diameter, (unit: m);

H -- pump design rated head, (unit: m);

ymax -- the maximum blade thickness at the hub, (unit: m);

K -- material coefficient.

conclusion

After years of technical improvement, combined with the feedback of the end users, the chlor-alkali evaporation circulation pump has been in the advanced ranks in terms of material, specification, size, manufacturing accuracy and so on. For different working conditions, evaporative circulating pump materials can be selected: stainless steel, duplex stainless steel, titanium, monel, has been able to successfully solve the corrosion problem. The application of the fifth generation evaporation circulation pump has been expanded from caustic soda evaporation to: ammonium phosphate, phosphoric acid, vacuum salt, alcohol, lactic acid, alumina, rutile, titanium dioxide, calcium chloride, ammonium chloride, refrigerant, molten salt, polyvinyl chloride and waste acid concentration and other industries. Installation form, not only the ground installation, hanging installation, but also to achieve floating installation pool surface.

What Is A Single Screw Pump? What Is A Progressing Cavity Pump?

Application of High Temperature Molten Salt Pumps in the Concentrating Solar Power Plant

Titanium Pumps/Titanium Centrifugal Pumps Are Essential In Chemical Industry

What Are the Water Filling Methods for Centrifugal Pumps(Part 3)?

What Are the Water Filling Methods for Centrifugal Pumps(Part 2)?