Learn - Dec. 15, 2025

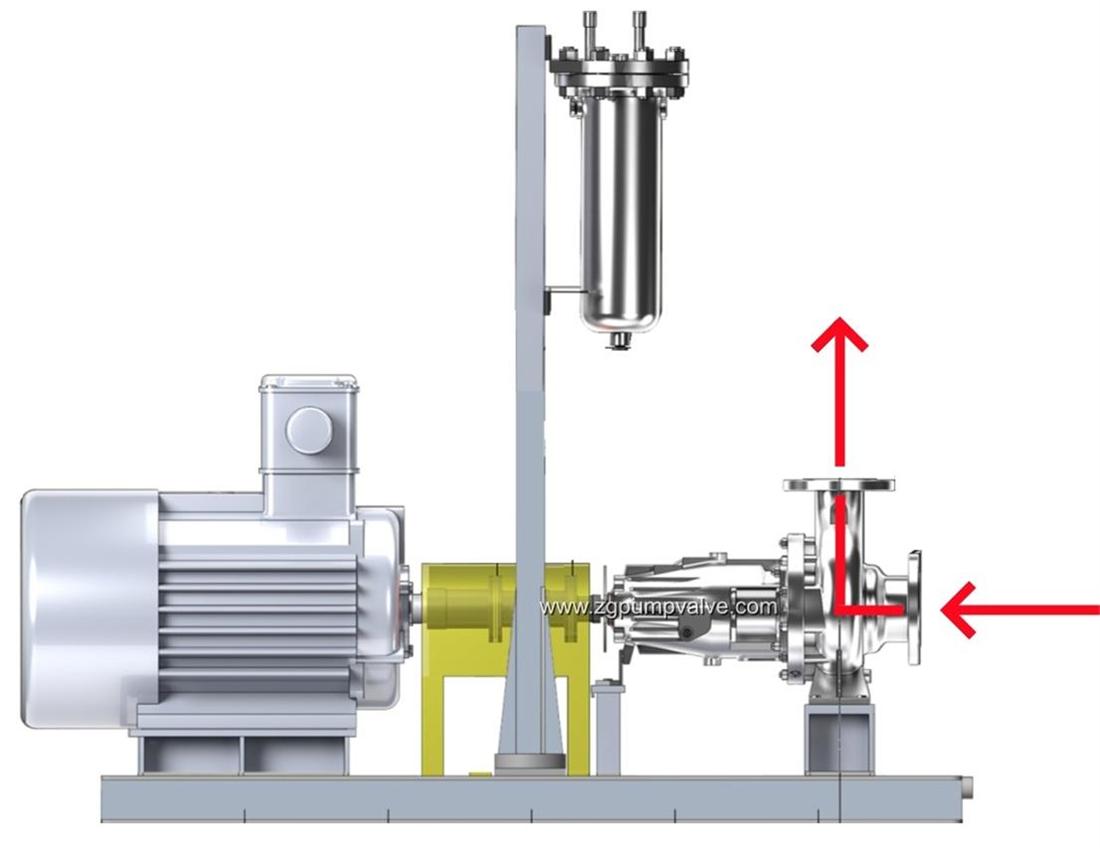

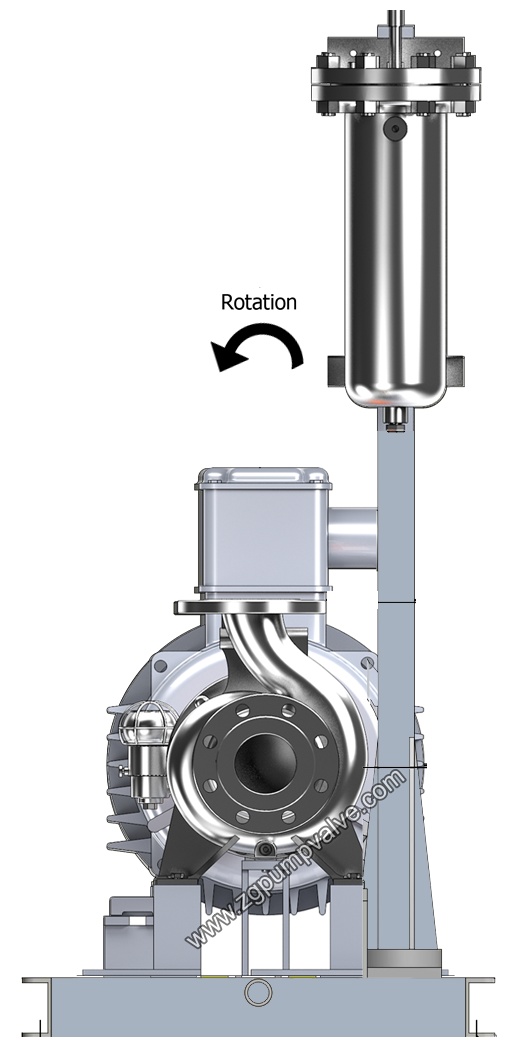

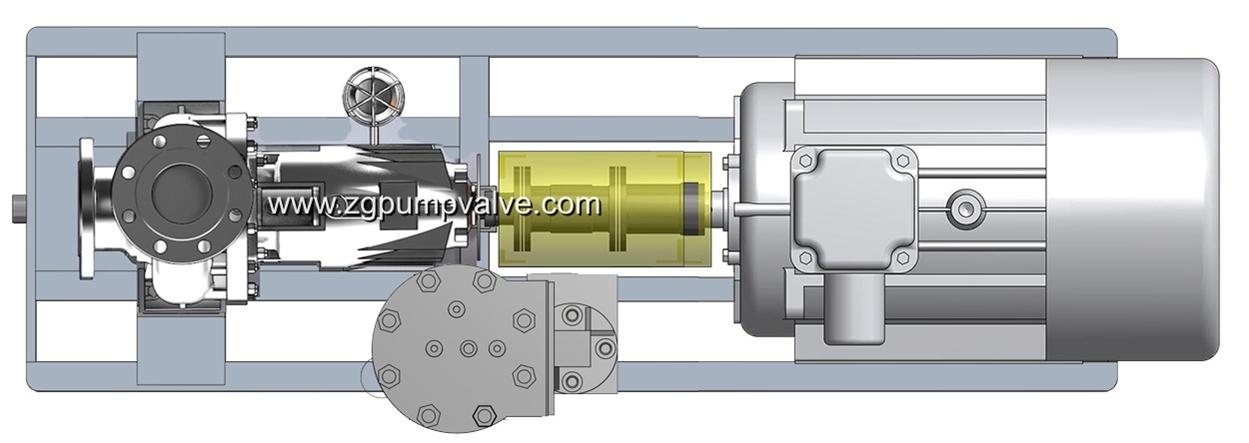

The end suction pump is also widely known as straight pump, which structure is typically single stage and single suction with cantilever impeller and back pull-out design. By understanding the name of those pumps, you may realize that the "end suction" means the place where the fluid flows into the pump. The most different part of the end suction pumps is their pump casing with L-shaped flow path compared to other type of pumps.

The correct model selection of end suction pumps is the precondition of smooth & energy-saving operation & long lifespan, the inconsiderate pump selection of pump and motor may cause more power consumption, more maintenance requirements, or even failure of your pumping devices. The following contents provide the essential factors for your consideration during the model selection of centrifugal type end suction pumps.

As one of the most important variants of centrifugal pumps, the end suction pumps share the same working principle with all the other centrifugal pumps. The fluid enters the pump through the pump suction nozzle at the pump end when the impeller starts to rotate and synchronously create negative pressure at the impeller center, then the impeller accelerates and pushes the fluid to the internal wall of the pump casing, this kinetic energy produced by the impeller is then converted into pressure due to the constraint of pump casing and finds its way out through the pump discharge nozzle.

The first thing to be completed before starting the model selection of end suction pumps is to finalize the pumping specifications, which directly affect the pump type, pump size, impeller type (closed, semi-open or open), motor size, etc. Below are the main specifications for your study:

● Flow rate (Typically in m3/h, LPM, GPM)

● Pump head (Typically in meters and feet)

● Pumping fluid composition (What are included in the fluid)

● Pumping fluid temperature (Typically in °C or °F)

● Pumping fluid specific gravity (Density of the fluid)

● Solid content percentage and their size, if any (What determines the impeller type)

● Pressure at the pump suction (This would affect the selection of mechanical seals)

● NPSHa (Net Positive Suction Head Available)

● Motor requirements (like voltage, frequency, indoor or outdoor, ex-proof type or not, protection class...)

● Preferred material of pump (Typically means the MOC of pump wetted parts)

By accomplishing the list above, the end suction pump manufacturer is able to do the model selection work in an accurate way.

It is important to receive the unique performance curves chart from pump manufacturer, you may find out the useful information of the pumps you are trying to get from them, typically a pump performance curves chart including the flow rate, head, efficiency and NPSHr value. By understanding the curves and their relationships in the chart, you may always keep your end suction centrifugal pump working near the best efficiency point and thus avoid the cavitation, vibration and abnormal noise. Make sure to follow the following tips during the selection of pumps.

● Selecting pumps near the BEP-neither far left nor far right

● NPSHr value matches the NPSHa value

● Taking fluid density into consideration for the shaft power calculation-avoiding overload of motor

NPSH stands for Net Positive Suction Head, which is the key factor of smooth operation for all the end suction centrifugal pumps, without knowing the requirements of NPSH for both pump and your application, the cavitation can happen to the pumps and cause damages.

● NPSHr=Net Positive Suction Head required, which is the minimum suction head required to make sure the pumps work without cavitation.

● NPSHa=Net Positive Suction Head available, which is the available suction head that your application has.

Important Tip: NPSHr value is at least 0.5 meters lower than NPSHa, otherwise the cavitation would happen.

Unmatched NPSHr value to the NPSHa value of your application may cause cavitation to your centrifugal end suction pumps, and lead to abnormal vibration, noise, temperature rising to bearings and damage to pump impeller.

The proper material selection for the end suction centrifugal pumps is the precondition of long service time of your pumping devices. The wetted parts of a pump mainly consist of the casing, impeller, impeller nuts, wear rings, shaft sleeve, pump cover, sometime the pump shaft is also a wetted part. The table below is the recommendation of pump wetted parts materials against different applications:

Applications | Pumping Fluids | Material Options |

Agriculture & Municipal Projects | River water & clean water | Cast iron, ductile cast iron, carbon steel |

Chemical plants | Chemical solutions | Stainless steels, Duplex Stainless steels, PFA lining, Titanium, Nickel, Hastelloy... |

Seawater Desalination | Sea water | Duplex stainless steel, bronze, Titanium |

Water Treatment | Sewage water | Cast iron, stainless steels |

Mining | Slurry | High chrome alloys |

Due to the restrictions of different installation conditions including pipelines and layout, you need to selection the correct installation type of end suction pump to fit your site, below are the suggestions of selection of pump installation:

Applications | Installation Types | Pump Types |

General Pumping Needs | Horizontal Installation | Horizontal End Suction Pump |

Building Water Supply | Vertical Installation | Vertical Inline Centrifugal Pump |

House Water Supply | Horizontal Installation | Horizontal Monoblock Pump |

Chemical Plants | Horizontal Installation | Heavy-Duty End Suction Pump |

The proper configuration of shaft sealing system is critical to the trouble-free operation of end suction pumps, different pumping fluids require totally different shaft sealing systems and flush plans, from the below table you may have a basic understanding of selection of shaft sealing systems against most widely seen pumping fluids

Pumping Fluid | Shaft Sealing Type | Flush Plan |

| Clean water at ambient temperature | Single mechanical seal or Packing Seal | API682 P01, P02, P11... |

| Hot water ≥120 °C | Single mechanical seal | API682 P21 |

| Caustic Soda solution, Brine, Sulphur Acid, Hydrochloric Acid <120 °C | Cartridge double mechanical seal | API682 P54 |

| Hot Oil ≥200 °C | Cartridge double mechanical seal | API682 P32+P53B |

The pump efficiency is the key factor that affects the motor power, higher pump efficiency means the lower power consumption.

● Pump model selection is supposed to be within the BEP range.

● Consider the proper safety margin, generally 15% for small pumps, 10% for big pumps.

● Select VFD motor for the needs of multiple flow rates.

Easy maintenance is one of the important features of the end suction pumps, the following considerations must be included during the selection of manufacturers.

● Pumps must be designed and built as per standards including ISO, ANSI, API...

● Pump spare parts must be interchangeable to save the cost of operation of pumps

● Lead time of pump spare parts must be as short as possible

● Availability of up-grading service

The comprehensive pre-sales services as well as after-sales supports from our company are the guarantee of smooth operation of your centrifugal end suction pumps.

No one born as an expert of everything, if you still have many doubts with the selection of end suction pumps for your applications after going through this article, please feel free to contact us for further consultations. We offer the following items to help you out:

● Model Selection Guidance

● Fluid Characteristics Analysis

● Pump Wetted Parts Material Selection

● Shaft Sealing Selection

● Flush Plan Recommendation

● Driving Power Calculation

● Tailor-made Pumping Solution

Let's take the below pumping application as an example:

● Flow rate: 100 (m3/h)

● Pump head: 50 meters

● Pumping fluid composition: 50% Caustic soda

● Pumping fluid temperature: 95 °C

● Pumping fluid specific gravity: 1400 kg/m³

Recommendation: A titanium made chemical centrifugal end suction pump would be the best solution for this corrosive fluid at high temperature, other type of pumps may not withstand both the corrosion and the high temperature from this harsh fluid. Furthermore, the cartridge double mechanical seal with flush plan 54 is the lowest requirement for shaft sealing against this demanding pumping application.

As the beating hearts to push the fluids through the process of pipelines, the correct model selection of end suction pumps is precondition of well-functioning of your plant. Before starting to do the selection, it requires the comprehensive understanding to your pumping requirements including flow rate, head, fluid characteristics, pump materials, shaft sealing and motor power calculation...Only with the well consideration of the above-mentioned specifications, can make sure the reliable and durable operation of your pumping equipment.

Working with reputable manufacturers of centrifugal end suction pumps may free you from a lot of troubles, as they always can select the right pump models that require less maintenance and with longer service life.

Contact us now: sales@zgpumpvalve.com wa.me(Whatsapp: +8613738006567)

Visit our workshops by VR Tour