Learn - Sep. 05, 2022

An Axial flow pump, is a high flow rate and low head fluid pumping equipment, which is also known as the Horizontal Axial Flow Pump, Elbow Pump, Forced Evaporation Circulation Pump, it is designed to handle large flow and low head of clear liquids or liquids containing crystallization. The axial flow pumps are widely used in agricultural drainage and irrigation, urban water supply and drainage, water transfer engineering, salt making, desalination project... Strictly speaking, it is not a centrifugal pump, its shape is also different from the regular chemical centrifugal pumps, it has a huge inlet and outlet, like a huge horn, the maximum diameter of the outlet can reach 1800mm, the impeller like a giant electric fan propeller. We often see these giant pumps in salt production, water treatment centers, desalination, mirabilite, alkali production, etc.

Horizontal axial flow evaporation circulation pump, used for large capacity, low head working conditions, as a transport or forced circulation pump, this article introduces the caliber of 1000-1800mm (big diameter ) large evaporation circulation pump. With its heavy-duty construction and flexible design, these series pumps ensure maximum reliability and are perfectly suitable for all kinds of large capacity low head industrial processes.

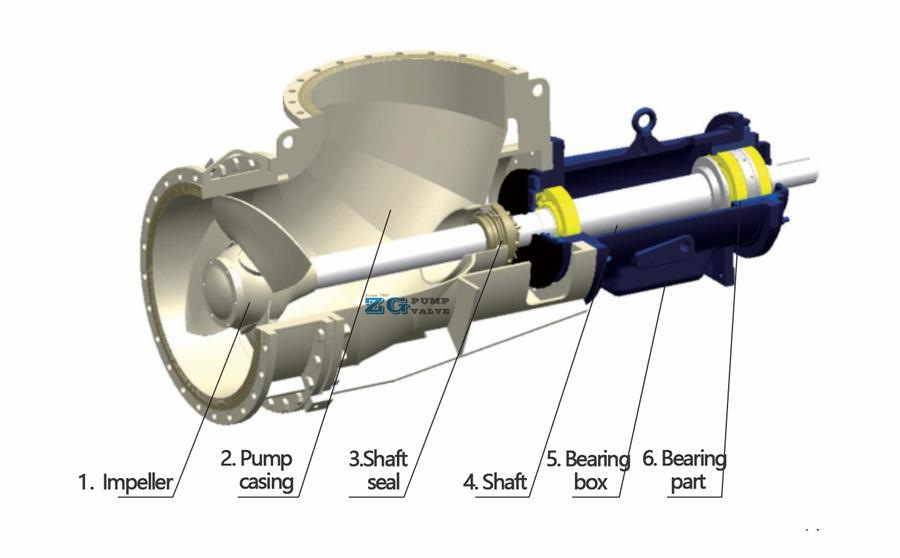

The horizontal axial flow pump is composed of the pump part and the transmission part. The pump is composed of the propeller, pump casing, shaft, bearing box and other components. Its typically structure is as below:

Propeller is cantilever supported type with spherical hub, blade can be adjusted, by adjusting the blade placed Angle,can achieve to broaden the range of pump performance parameters. The blade shape of horizontal axial flow pump is a three-dimensional twisted structure. By using the Clearance Flow Numerical Simulation Theory and based on the CFD platform, optimize hydraulics and promote propeller profile performance, provides high efficiency while reducing net positive suction head (NPSH). The propeller of axial flow pump is carried out unsteady numerical calculation of the whole flow field, and the theoretical 3D impeller model with the best hydraulic model is designed. The propeller is provided with a short tube, easy to adjust the clearance of the impeller outer edge.

performance parameters. The blade shape of horizontal axial flow pump is a three-dimensional twisted structure. By using the Clearance Flow Numerical Simulation Theory and based on the CFD platform, optimize hydraulics and promote propeller profile performance, provides high efficiency while reducing net positive suction head (NPSH). The propeller of axial flow pump is carried out unsteady numerical calculation of the whole flow field, and the theoretical 3D impeller model with the best hydraulic model is designed. The propeller is provided with a short tube, easy to adjust the clearance of the impeller outer edge.

The pump casing is also known as the pump body, the pump shell, which is a curved pipe flow channel design, is a very vivid Elbow Pump, the pump body is modular Mosaic welding. For special High Pressure conditions, the integral forging molding is adopted. The axial flow pump can be mounted by hanging on the pipe, with advanced thermal compensation technology. The installation of ZW horizontal axial flow pump can be done without the base plate, and there is no expansion joint on the entire pipeline, which can save a lot of procurement costs for the end user. Therefore, our horizontal axial flow pumps are often used with evaporator, crystallizer, reactor, cantilever installation structure is conducive to coordination and unity with the evaporation system.

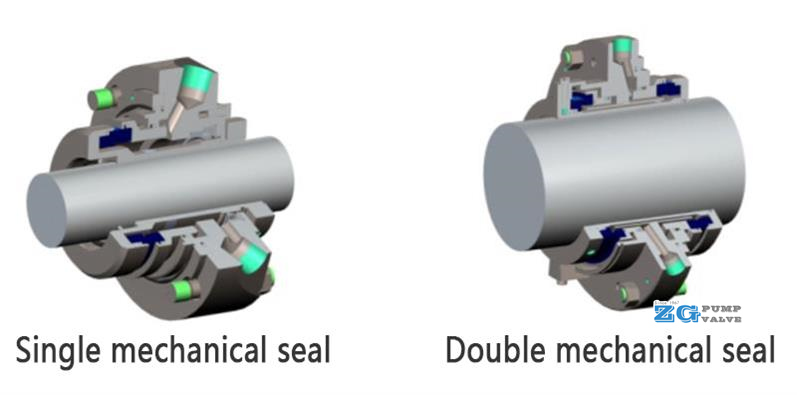

According to the working condition, there are different shaft sealing systems for axial flow pumps, but generally the most widely used are packing seal, single mechanical seal, or double mechanical seal.

■Packing seal, efficient and simple, packing seal for inner and outer sealing, replacing packing, no need to stop operation, so it is really fast and convenient.

■ Single mechanical seal, conforms to API682, flush Plan02 or Plan32 or Plan54. Choose the flushing water pressure according to the requirements of working conditions. The flow rate is usually 3-26L/min. Turn on the flush water 5 minutes before starting the axial flow pump, and then turn it off 5 minutes after stopping the axial flow evaporation forced circulation pump.

■ Double mechanical seal, conforms to API682, flush Plan54. The flushing water pressure is 1-2bar higher than the sealing chamber pressure, and the flow rate is usually 6-52L/min. Turn on the flush water 5 minutes before starting the propeller pump, and then turn it off 5 minutes after stopping the operation.

is 1-2bar higher than the sealing chamber pressure, and the flow rate is usually 6-52L/min. Turn on the flush water 5 minutes before starting the propeller pump, and then turn it off 5 minutes after stopping the operation.

Mechanical seal can achieve no leakage, no pollution to the environment, so that the service life of the horizontal axial flow pump is longer, ensuring the safety of the working environment, ECO-friendly. Most of the end users choose mechanical seal as the shaft sealing system for their axial flow pumps.

Last but not least, the packing seal and the mechanical seal can be interchanged with only a small number of replacement parts. That's pretty cool.

The shaft of an axial flow pump, according to the different user's budget, can be butt welding shaft, cladding shaft or complete shaft.

①Butt welding shaft, the full name is butt welding type hot cladding shaft, carbon steel shaft with excellent mechanical properties and corrosion resistance titanium shaft butt welding together, the outer surface of butt welding shaft is wrapped with a shaft sleeve, butt welding type hot cladding shaft can meet the requirements of corrosion resistance, high temperature resistance, wear resistance.

②Cladding shaft, a material with corrosion resistance is wrapped around a carbon steel shaft.

③Forging and forming one shaft. Heavy paired duty shaft provides maximum strength and stiffness in severe pumping conditions. The forging and forming shaft not only has corrosion resistance but also provides bearing capacity and operation stability.

Pre-loaded bearings for easy assembly and maintenance. The bearing box is designed for large space oil storage. There is oil level observation port, so that the bearing can be fully lubricated and cooled to ensure the long-term normal operation of the bearing.

Transmission part, the axial flow pump in the whole chemical process is to provide circulating power when the feed liquid is concentrated and crystallized, promote the circulation of the feed liquid, improve the heat transfer coefficient of the feed liquid evaporation process, avoid the damage to the crystal, often running at low speed. ZW Horizontal Axial Flow Pump is slow type axial flow pump technology, will not destroy the crystal, small cavitation margin, stable operation. It could be chosen belt pulley, reducer, connected electric motor. When the motor power is ≥200kw, it is recommended to choose universal joint drive and reduction gears.

Connected to the pump elbow, the bearing housing of an axial flow pump is used to install the bearings and shaft of the pump. In order to cool the bearings, the certain amount of lubricant oil must be filled into the bearing housing before starting the pump, otherwise the life of bearings can be sharply reduced.

The base plate of an axial flow pump is a plate which all the pump parts are assembled onto, however, sometimes, the pump and motor can be installed onto separate base plate according to the requirements from clients.

● High efficiency: Those pumps are designed to decrease the fluid dynamic losses through shorter impeller blades, which reduce fluid rotation effects in the same time, while their optimized propeller and guide vane configurations decrease turbulence and impact losses within the pump casing (also called the elbow), ensuring smooth internal flow. Therefore, the pump efficiency of axial flow pumps is normally higher than regular centrifugal pumps.

● Wide applied range: Not only in chemical industries, but also in many other applications can find the axial flow pumps, such as irrigation, flood control and municipal projects...

● Less maintenance: Compared to centrifugal pumps, one axial flow pump mainly consists of only a few piece of pump parts, which means it requires less maintenances than other type of pumps, thus can reduce the cost of operation a lot.

● Performance adjustable: Not like other type of pumps, the axial flow pump has a propeller which blades can be adjusted to various angles to meet the different flow rate and head to fit the multiple requirements in client's applications.

There are various materials available for the wetted parts of the axial flow pumps, the correct selection of pump materials is crucial to the long lasting and smooth running of pumps. From the below table, you may have a basic understanding to the material selection of such pumps against different applications. Should you have any further doubts of the pump material selection for your specific application, as a professional manufacturer of axial flow pumps, we offer tailored solutions to help you out.

| Application | Pump Type & Structure | Material of Construction |

| Waste Water Treatment | Vertical & Submersible | Cast Iron, Carbon Steel |

| Municipal Projects | Vertical & Submersible | Cast Iron, Carbon Steel |

| Chemical Plants | Horizontal & Vertical | Stainless Steels, Titanium, Monel... |

| Seawater Desalination | Horizontal & Vertical | Duplex Stainless Steels |

Axial flow pump is suitable for high flow, low head conditions, conveying clear liquid or solution containing a small amount of crystallization.

■ Salt making requires the axial flow pumps as the evaporative forced circulation pumps

■ phosphoric acid making process requires evaporation forced circulation pump

■ Mirabilite industry requires evaporative forced circulation pump

■ Alumina industry requires evaporation forced circulation pump

■ Sugar industry requires evaporation forced circulation pump

■ Water and wastewater treatment processes MVR project

■ Desalination projects circulating pump

■ Ammonium phosphate plant requires evaporation forced circulation pump

■ Combined alkali and ammonium ammoniate plant pump

■ Cold precipitation axial pump

■ Salt precipitation axial flow pump

■ Scrubber axial flow pump

■ The cooling axial-flow pump used in caustic soda plant evaporators

Axial flow pumps, as the leading and typical pumping devices for large flow rate and low discharge head, play an essential role in various industires due to their reliability and operational cost-effective features. However, due to the highly customized features of such products, the selection of right models of axial flow pumps requires professional background to make sure the long time and smooth operation of those pumps. As a designer and manufacturer of those pumps, we offer tailored made axial flow pumps based on the specific requirements from our clients from all over the world.

Contact us now: sales@zgpumpvalve.com or wa.me(Whatsapp: +8613738006567)

Visit our workshops by VR Tour