Chemical Pump

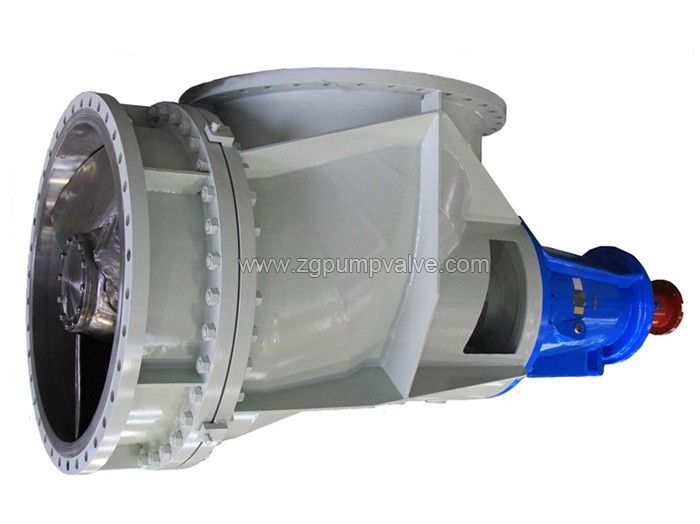

Horizontal chemical axial flow pump

The horizontal chemical axial flow pumps are also known as chemical propeller pumps and chemical elbow pumps, which are designed to handle both highly corrosive and clear liquid in high-flow and low-head applications. Pump discharge diameter from 200 to 1800 mm( 8 to 72 inches) In MVR water treatment, salt making, alumina, mirabilite, alkali industry, sugar making, seawater desalination and other industries as a transport or forced circulation evaporation pump . A wide range of high-quality materials deal with different medium: stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

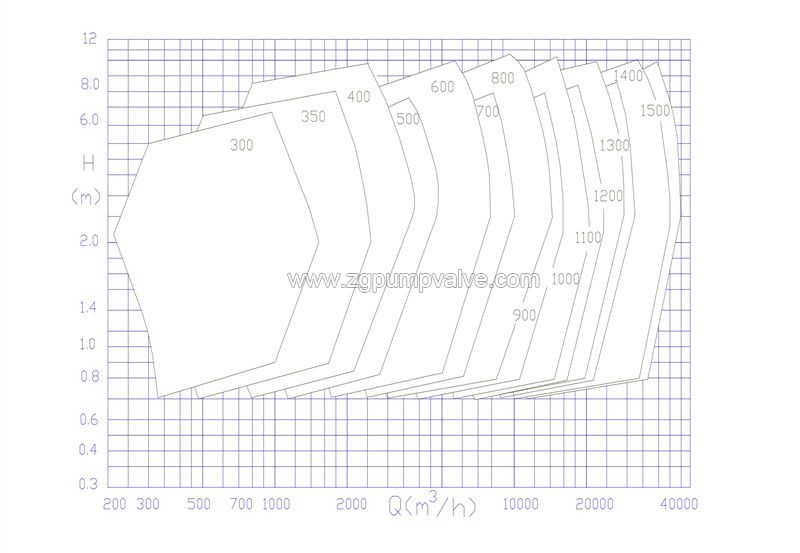

Performance

The axial flow pumps have wide performance range, and can be made from various materials including Titanium, Super Duplex Stainless Steels, Hastelloy...

■ Flow rate: Q=250~55000(m³/h)

■ Total head: H=8~1.5 (m)

■ Speed: n=180~1450rpm

■ Fluid s.g.: γ ≤1.5

■ Fluid temperature: T=0~180℃

■ Fluid viscosity: ν ≤600(mm2/s)

■ Pump diameter: Ф200mm~1800mm

Axial flow pumps are particularly designed and built for large volume flow rate and low discharge pressure applications, they are capable of conveying big flow rate of fluid with comparatively low pressure in a efficient way. Therefore, the axial flow pumps are the ideal pumping device for effective handling of large volume fluid with low power consumption.

■ Adjustable propeller blade for different working requirements,expand the application range and improve the versatility of pump.

■ Slow speed design,no damage to crystal medium,small NPSH,smooth operation.

■ This pump type, is also known as elbow pump, its main body adopts elbow structure, adopts modular splicing assembly welding or integral forging molding, good hydraulic performance.

■ Suspension installation, no pump base plate, no expansion joint.

■ Pre-assembled bearing for easy assembly and maintenance.

■ Slight vibration, low noise, smooth operation, high efficiency and energy-saving.

1. Types of shaft seals available for axial flow pumps:

■ Soft packing

■ Single mechanical seal

■ Double mechanical seal

Mechanical seal and packing seal can be interchangeable

2. Center line mounted pump casing

3. The installation and transmission of axial flow pump has a variety of forms.

4. Pump and motor can be used triangle belt transmission, gear transmission, direct transmission.The big diameter large axial flow pumps should adopt the universal joint transmission.

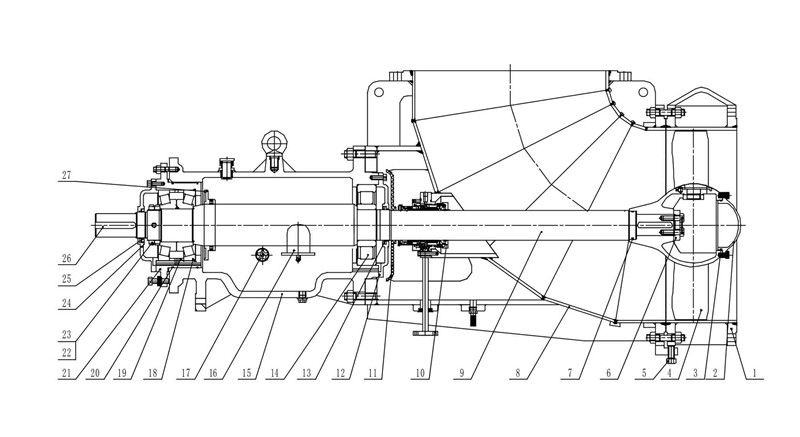

Structure drawing is as below

1. Casing 2. Impeller hub cover 3. O-ring 4. Impeller 5. Adjust bolt 6. Gland plate 7. O-ring 8. Elbow 9. Shaft | 10. Catridge mechanical seal 11. Water retaining ring 12. Front bearing cover 13. Skeleton oil seal 14. Front bearing 15. Bearing housing 16. Oil level gauge 17. Oil leveler 18. Rear bearing | 19. Bearing spacer 20. O-ring 21. Bearing box 22. Lock nut 23. Retaining gasket 24. Rear bearing cover 25. Skeleton oil seal 26. Key 27. Oil flinger |

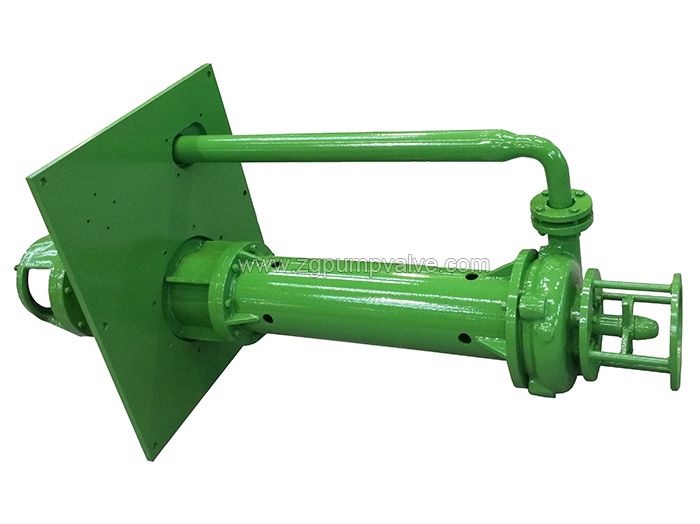

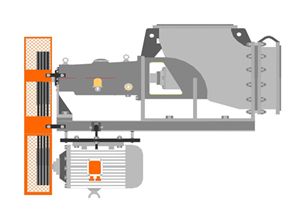

| K-pipe hung arrangement No baseplate for both pump and motor,no expansion joint on pipe. The Axial Flow Pump is driven by motor through V-belts.This arrangement is only applicable for the pump diameter from 300-500mm and motor capacity below 55Kw. |

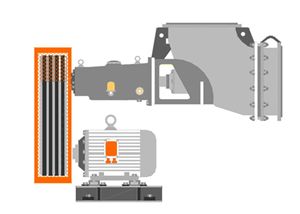

| E-half pipe hung arrangement No baseplate for axial flow pump,pump is hung on the pipe,no expansion joint on pipe.For big axial pumps above 700mm diameter,there must be a fluctuating frame at the horizontal pipe connecting the pump.Only V-belts and universal joint are recommended as the transmission method for this arrangement. |

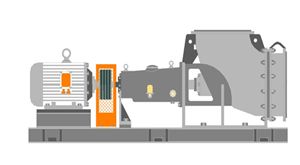

| F-horizontal arrangement Baseplate is required for both axial pump and electric motor. An expansion joint on the pipe is also required for high temperature applications.Transmission methods can be V-belts and direct coupled. |

| For easy maintenance purpose,the above mentioned arrangements require a casing between horizontal pipe and the aixal flow pump. | |

Chemical axial flow pumps are typically constructed from stainless steel (304/316/316L) or duplex steel for corrosion resistance. Some special applications may use nickel alloys, Monel, Hastelloy or polymer-coated components for highly corrosive chemical handling. For example, Titanium Axial Flow Pumps are widely used in salt making industries. Below are the detail material constructions of our axial flow pumps:

| The name of material | The code name of materials | The name of spare parts | |||

| International standard | American standard | Impeller | Impeller cover | Pump body (with casing) | |

Corrosion resistant cast iron | Aluminum cast iron gray cast-iron nodular cast iron Cr28 Cr30 | C.I D.I | ● ● ● ● | ● ● ● ● | |

| Carbon steel | Q235-A 23 25 | A A36 WCA WCB | ● ● | ||

Stainless steel | (ZG)00Cr18Ni10 | CF-3(SS304L) | ● | ● | ● |

| (ZG)0Cr18Ni9 | CF-8(SS304) | ● | ● | ● | |

| (ZG)0Cr18Ni12Mo2Ti | CF-8M(SS316) | ● | ● | ● | |

| (ZG)00Cr17Ni14Mo2 | CF-3M(SS316L) | ● | ● | ● | |

| (ZG)0Cr18Ni9Ti | CD-4MCu | ● | ● | ● | |

| (ZG)1Cr18Ni9Ti | Monel | ● | ● | ● | |

| (ZG)1Cr18Ni12Mo2Ti | ● | ● | ● | ||

| NO.20 alloy | ● | ● | ● | ||

| 1Cr13 | ● | ● | ● | ||

Duplex Stainless steel | 0Cr26Ni5Mo2 | (AlSi)329 | ● | ● | ● |

| 0Cr17Mn13Mo2N | ● | ● | ● | ||

| 00Cr18Ni5Mo3Si2 | ● | ● | ● | ||

| Anti-corrosion alloy | TA1、TA2、TA3 | Monel | ● | ● | ● |

| TA9、TA9-1 | H-B | ● | ● | ● | |

| TA10 | H-C | ● | ● | ● | |

| Ni-Resist1 | ● | ● | ● | ||

| Ni-Resist2 | ● | ● | ● | ||

| Ni-Resist3 | ● | ● | ● | ||

The chemical axial flow pumps are fully customized products which have quite different configurations from the pump materials, the structures and the outsourced parts like electric motors. Below are the options of the configurations for our axial flow pumps:

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Gear box |  | Reputed China brand | SEW, Shandong Chenghua, Zhengzhou machinery instituteSiemens, Flender |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

ZW chemical axial flow pumps are mainly applicable for the applications of big flow rate and low total head, like force circulation pump for falling film evaporator systems:

■ MVR water treatment evaporation concentration process

■ Single effect and multi effect forced evaporation circulating Titanium axial flow pump for vacuum salt making

■ Forced evaporation circulating pump for alumina industry

■ Single - effect and multi - effect forced evaporation circulating pump for mirabilite production

■ Forced evaporation circulating axial flow pump for alkali industry

■ Forced evaporation circulating pump for sugar industry

■ Sea water desalination evaporation circulating pump

■ Chemical process industry

■ Water and wastewater treatment

1. How Does an Axial Flow Pump Work?

First of all, the fluid to be pumped enters through the pump's suction port and reaches the elbow of the pump, where it comes into contact with the impeller blades. The rotation of the impeller causes the fluid to move axially. Key parameters such as the impeller diameter, rotation direction, and blade angle jointly determine the pump's flow rate, fluid direction, and pressure output. As the blades rotate, they convert the fluid's kinetic energy into pressure energy, thereby increasing the fluid pressure proportionally with the increase in rotational speed. Once the fluid reaches the desired pressure level, it is discharged through the impeller outlet of the axial flow pump.

In summary, the axial flow pump accelerates the fluid from the suction end to the discharge end through the rotational movement of its impeller blades. Due to this working principle, the axial flow pump is an ideal choice for applications that require high flow rates while maintaining a relatively low discharge pressure.

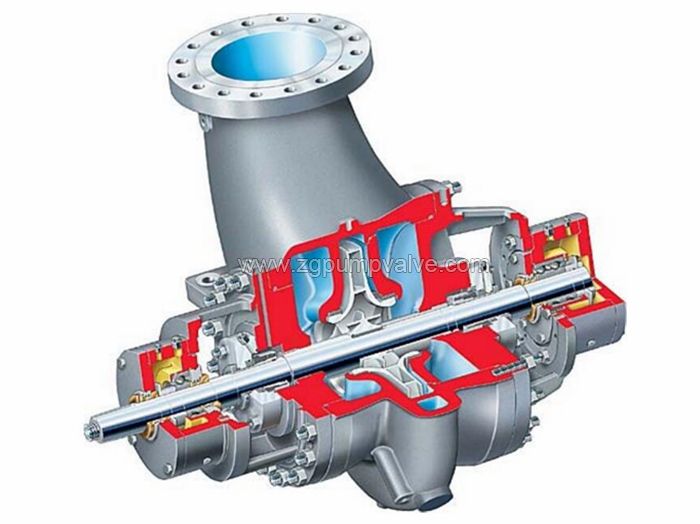

2. What Is the Structure of an Axial Flow Pump?

An axial flow pump primarily consists of a pump casing (or pump elbow), an impeller, a pump shaft, and a mechanical seal. The impeller is mounted at the pump inlet, while the pump elbow serves as the outer housing, enclosing all internal components. Together, these parts work to direct fluid flow and generate pressure within the pump.

2.1 Suction & Discharge

The suction and discharge directions of the axial flow pump can be customized according to customer requirements, and they can be interchanged. Usually, this pump adopts a structure of suction at the end and discharge at the top, but there are also other configurations available to meet specific application needs.

2.2 Impeller

The impeller is the core component of an axial flow pump. Its characteristic is that multiple inclined blades are installed on a central hub. When the pump shaft rotates, the design of the blades will interact with the fluid, thereby forming a directional flow along the axial path of the pump.

2.3 Pump Bearings

The pump shaft is the central component of the entire rotating system, supporting the impeller and mechanical seal. Its diameter and structural strength must be precisely designed to withstand the stresses generated during operation. The bearing system plays a dual critical role: maintaining the precise alignment of the rotating components (impeller and mechanical seal), and reducing rotational friction. The bearing configuration used for different pumps varies greatly, and each design is customized according to specific load and performance requirements of the axial flow pump.

2.4 Sealing System

The shaft seal is of vital importance at the connection point between the pump elbow pipe and the rotating shaft in an axial flow pump. Its function is to prevent liquid leakage. Currently, there are mainly two sealing methods: mechanical seal and packing seal. However, the packing seal no longer meets modern environmental protection standards, while the mechanical seal has become the preferred solution in the industry due to its outstanding sealing reliability (especially when dealing with chemical solutions).

2.5 Bearing Housing & Base Plate

The bearing housing of the axial flow pump serves as the installation structure for the pump bearings and the rotating shaft, and also provides a connection interface for the pump casing (often referred to as the pump elbow pipe). The base plate acts as the foundation support platform, integrating all the main pump components such as the pump casing, the bearing housing, and the prime mover (such as an electric motor or diesel engine) into a complete unit.

2.6 Seal Flushing System & Bearing Lubrication

To prevent the axial flow pump from being damaged due to high temperature, a reasonable flushing plan must be formulated to cool the mechanical seal chamber and dissipate the accumulated heat. Moreover, for the bearings that support the shaft, adequate lubrication is crucial because they generate a large amount of friction heat during operation - the bearing housing must be filled with lubricating oil up to the specified level to ensure that both bearings and the shaft components are adequately lubricated, thereby achieving optimal performance.

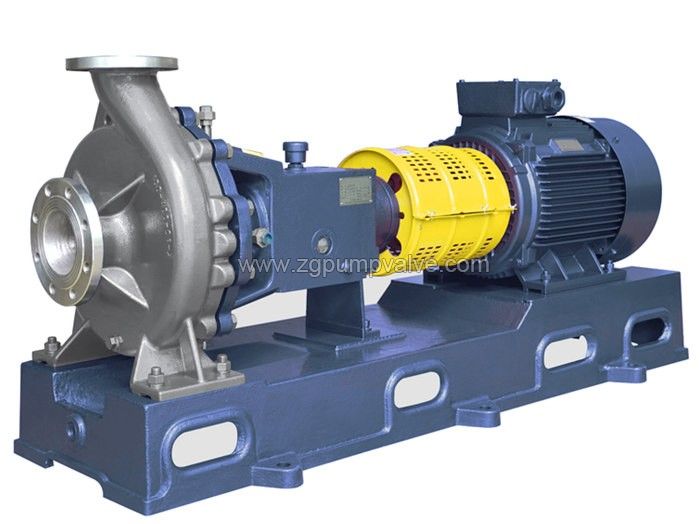

2.7 Driving Unit

The rotation of the impeller is powered by the drive unit, which transmits torque through a coupling that connects the drive shaft and the pump shaft. Axial flow pumps can be connected to various drive devices, including electric motors, diesel engines or turbines, to meet the specific needs and application requirements of different customers.

3. Characteristics & Advantages of Axial Flow Pumps

Axial flow pumps are specifically designed for high-capacity and low-head applications, and can efficiently convey large volumes of fluid with relatively low discharge pressure. Their optimized design enables effective handling of large flow rates while maintaining energy-efficient operation.

3.1 Higher Efficiency

3.11 Less Dynamic Loss. The axial flow pump's impeller features shorter blades that minimize fluid rotation, thereby reducing dynamic losses and improving hydraulic efficiency.

3.12 Specialized Design. The axial flow pump adopts advanced dynamic design principles. The configuration of the impeller and guide vanes has been optimized to minimize the turbulence and impact losses within the pump casing (pump elbow). This meticulously designed approach ensures that the fluid flow throughout the entire pump chamber is extremely smooth.

3.13 Higher Energy Conversion. During operation, the axial-flow pump uniformly sucks the liquid into the rotating impeller through its suction port. Here, the mechanical energy of the driving device is converted into pressure energy and kinetic energy through centrifugal force. Subsequently, the guide vanes efficiently direct this energy-rich fluid through the pump casing (elbow) and reduce energy loss, thereby achieving the usually high efficiency of this system.

3.14 Excellent Sealing & Lubrication Systems. The mechanical seals in the axial flow pump play a crucial barrier role, preventing contaminants from entering the pump casing. At the same time, the lubricating oil in the bearing box can maintain the stability of the shaft, reduce friction during operation, and improve energy efficiency throughout the pumping process.

3.2 Multi-purpose Applications. Axial flow pumps have extensive applications in various industries, including flood control systems, water conservancy projects, environmental protection projects, and chemical production processes, etc.

3.3 Low-Maintenance Design: Axial flow pumps feature a simplified construction with fewer core components, significantly reducing maintenance requirements compared to centrifugal pump systems.

3.4 Performance Adjustability Some axial-flow pumps are equipped with propeller blades driven by hydraulic power. These blades can be dynamically adjusted during operation to meet different flow requirements. This real-time control of blade angles can achieve optimal performance under various operating conditions and maintain the pump's efficiency.

3.5 Structural Customizability: The axial flow pump offers fully customizable installation configurations to meet the specific requirements of each project. It includes various drive options (direct coupling, gearbox drive, V-belt drive or pipe installation) as well as adjustable vertical column lengths designed according to the specific requirements of the customers. This flexible design approach ensures optimal integration with existing systems while meeting unique space needs.

4. Where the Axial Flow Pumps Can be Used?

4.1 Chlor-alkali Application: Chemical axial flow pumps meticulously manufactured using titanium alloys or super duplex stainless steels possess outstanding corrosion resistance when handling corrosive media such as caustic soda, chlorine alkali, and brine solutions. They can maintain stable performance even at temperatures as high as 130°C. These robust materials ensure reliable operation in the most demanding chlor-alkali processing environments.

4.2 Lithium Battery Application: The rapid growth demand in the electric vehicle industry has made high-flow axial flow pumps extremely important in the processing of lithium, as their outstanding flow capacity can effectively promote the crystallization of lithium carbonate. These specialized pumps perform exceptionally well in lithium-rich brine concentration and solvent recovery systems, providing reliable forced circulation performance, which is crucial for efficient production of battery materials.

4.3 Fertilizer Production Application: The high-efficiency axial flow pump is the preferred solution for the ammonium nitrate and urea evaporation system. In multi-effect evaporators, its large flow design significantly improves the heat transfer efficiency. By optimizing the forced circulation performance, these pumps can reduce energy consumption compared to traditional pumps, thereby directly enhancing the operational efficiency of the fertilizer production process.

4.4 MVR & ZLD Application: Axial flow pumps are highly efficient circulation pumps suitable for demanding industrial applications. These applications include MVR/ZLD multi-effect evaporators for treating high-salinity wastewater and large-scale heat exchange systems that require a large capacity for cooling water circulation. Their robust design ensures reliable operation when handling liquids with high total dissolved solids (TDS), and they can also save energy while maintaining high efficiency.

4.5 Evaporation Crystallization: Axial flow pumps are Specifically designed for precision evaporation systems, the low-speed chemical axial flow pump provides an ideal circulation system for applications sensitive to crystals (such as salt-water concentration and pharmaceutical production). Its gentle pumping action (operating range of 50 - 70 revolutions per minute) can maintain fluid flow while not damaging the integrity of the crystal structure, and its corrosion-resistant construction ensures reliable performance even when in contact with strong acidic chemical solutions.

4.6 Irrigation and Flood Management Solutions: Vertical and horizontal axial flow pumps are widely used in agricultural and flood control applications due to their strong water transportation capacity, which enables them to quickly convey large volumes of water under high-efficiency requirements.

4.7 Wastewater Treatment Application: Axial flow pumps are key components in wastewater treatment plants. With their high flow capacity and anti-clogging design, they can achieve efficient transportation of wastewater between treatment stages. These chemical axial flow pumps can reliably handle raw sewage containing up to 5% solids, while maintaining 20% to 30% higher energy efficiency compared to traditional solutions. Therefore, they are highly suitable for continuous operation processes such as primary treatment, aeration, and final discharge.

4.8 Application in Shipyards and Terminals: Vertical axial flow pumps are indispensable drainage equipment in shipyards and terminals. With their powerful drainage capacity, they can efficiently remove accumulated water during the start-up and maintenance operations of ships.

4.9 Application in Shrimp Farming: Axial flow pumps are highly suitable for shrimp farming operations. Due to their high pumping capacity, they can meet the urgent need for rapid water exchange in both saltwater and freshwater farming systems.

Company video

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

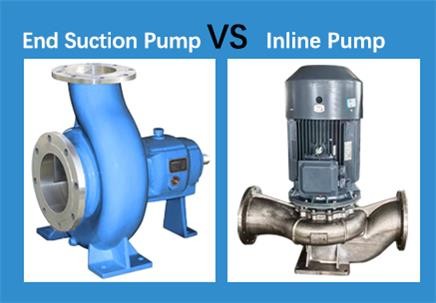

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

+86 28 8218 1182

-

+86 28 8218 1182