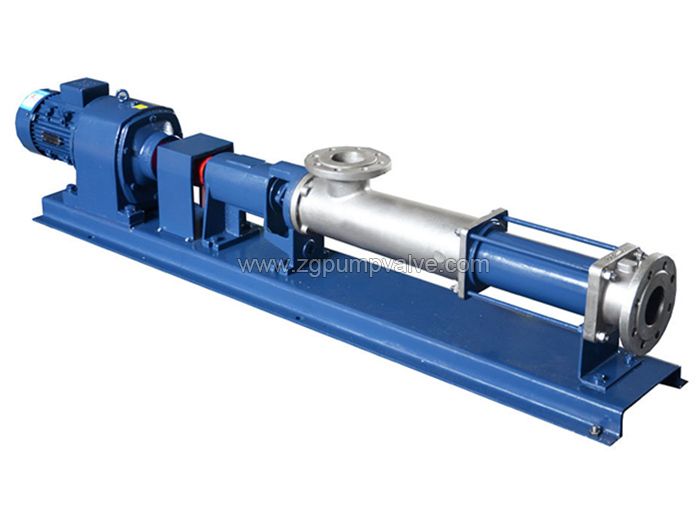

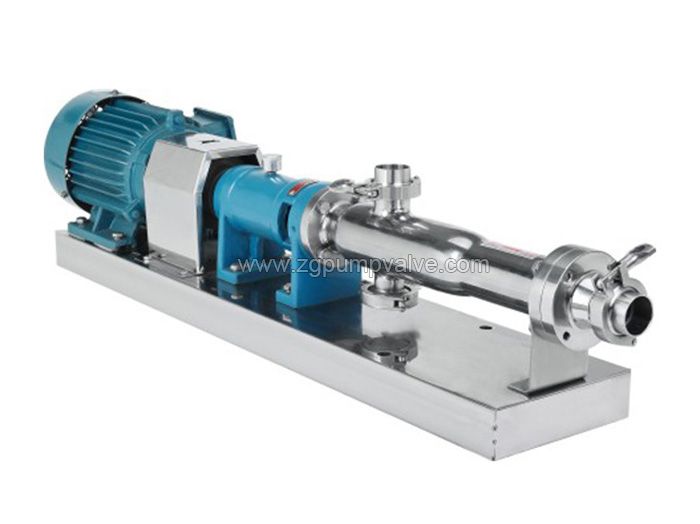

Screw Pump

Single screw pump

The biggest characteristic of single screw pumps(also known as progressive cavity pumps) is strong adaptability to medium, stable flow, small pressure pulsation, high self-priming capacity and pressure of 0.6~ 1.2MPa, which can meet the different needs of users for single screw pumps.There are various materials available for our single screw pump, including stainless steel SS304, SS316, SS316L, 904L, duplex stainless steel CD4MCu, 2205, 2507, Alloy 20, Hastelloy, Titanium, Monel, Nickel...

-

Parameters

-

Features

-

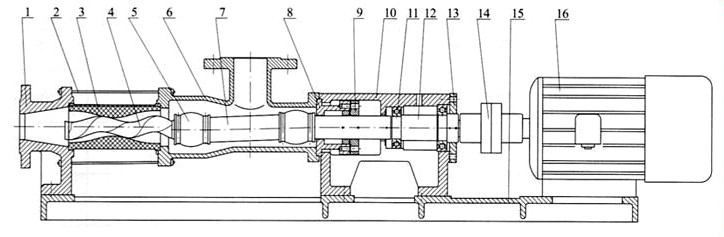

Structure

-

MOC

-

Configuration

-

Application

-

Performance

■Flow rate: Q=1~166m3/h

■Pressure: H=0.6/1.2 Mpa

■Speed: n=380rpm/720rpm/960rpm

■Temperature: T=-20~120℃

■The single-screw pump is a new type of pump that works on the principle of oscillating meshing volume. The main working parts are eccentric screw (rotor) and fixed bushing (stator).

■Due to the special geometry of the two components, a separate sealing cavity is formed, the medium is uniformly propelled by the axial direction, the internal flow velocity is low, the volume remains unchanged, and the pressure is stable, so that eddy current and agitation are not generated. The output pressure of each pump is 0.6MPa, the head is 60m (clear water), and the self-priming height is generally above 6m. The drive can be directly driven by a coupling or by a speed-regulating motor, a three-corner belt, a gearbox, etc. The pump has few parts, compact structure, small size and easy maintenance. The rotor and the stator are the wearing parts of the pump, and the structure is simple and easy to assemble and disassemble. Since the stator is made of a variety of elastic materials, the pump delivers high viscosity fluids and transports containing hard suspension particulate media or fiber media, which are not suitable for general pumping. The flow rate is proportional to the speed.

1. Discharge casing 2. Connection rod 3. Stator 4. Screw shaft 5. Universal joint | 6. Suction chamber 7. Intermediate shaft 8. Seal cover 9. Axial seal components 10. Bearing housing | 11. Bearing 12. Transmission shaft 13. Bearing cover 14. Couplings 15. Bracket 16. Motor |

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(304L) CF-8(304) CF-8M(316) CF-3M(316L) CN-7M(320) CD-4MCu |

| 2 | Stator | ||||||

| 3 | Rotor | ||||||

| 4 | Suction chambe | ||||||

| 5 | Intermediate shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 6 | Bearing housing | Cast iron | |||||

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

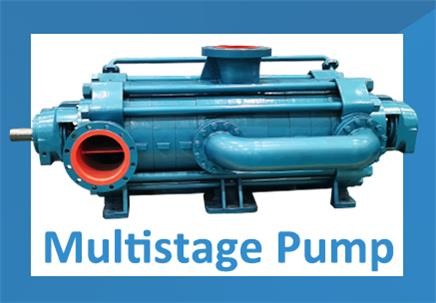

Generally, the single-screw pump can be used as a multi-purpose pump. The running speed of the pump can be high or low. The rated pressure of the outlet of the pump can be increased with the number of stages of the pump. For each additional stage, the pressure is increased by 0.6MPa. , so the scope of use is extremely wide.

■Environmental protection: the transportation of industrial sewage, domestic sewage, muddy water containing solid particles and short fibers. It is especially suitable for equipment such as oil-water separators and plate and frame filter presses.

■Shipbuilding industry: transportation of medium such as wheel bottom cleaning, oil water, oil residue, oil sewage, etc.

■Petroleum industry: transporting crude oil, in later oil fields, using a screw pump to inject polymer into the formation to increase oil recovery.

■Medicine, daily: a variety of thick paste, emulsion, a variety of ointment cosmetics and other transport.

■Food canning industry: a variety of viscous starch, cooking oil, honey, syrup, fruit pulp, butter, fish gizzard and its scraps.

■Brewing industry: all kinds of fermented viscous liquid, distiller's grains, grain products, slag, various sauces, pulp and the transportation of mucilage containing massive solids

■Construction industry: spraying and conveying of cement mortar, lime slurry, paint and other pastes.

■Mining industry: sewage, muddy water, etc. containing solid particles in the mine are discharged to the ground.

■Chemical industry: transportation of various suspensions, greases, various colloidal pulps, and various adhesives.

■Printing and paper industry: high viscosity ink, PVC polymer paste for wallpaper, pulp of various concentrations, short fiber slurry, etc.

The Versatility and Efficiency of Single Screw Pumps

When it comes to moving fluids efficiently, few technologies match the reliability of screw pumps. These ingenious devices have been around for decades, yet they remain indispensable in industries ranging from oil and gas to food processing. What makes them so special? Let's break it down in simple terms.

How Screw Pumps Work?

At their core, screw pumps use rotating helical screws to transfer liquids or semi-solids. Imagine a corkscrew moving through a bottle—this same principle applies, but on a larger, more precise scale. Typically, one or more rotating screws mesh with a fixed cavity, creating sealed chambers that push fluid from the inlet to the outlet. This design ensures smooth, pulsation-free flow, which is crucial for sensitive applications.

Why Industries Love Them?

1. Handling Thick Fluids with Ease

Unlike centrifugal pumps that struggle with viscous liquids, screw pumps excel at moving heavy oils, slurries, or even chocolate in food production. Their gradual displacement prevents shear damage, making them ideal for delicate or non-Newtonian fluids.

2. Energy Efficiency

Screw pumps maintain high efficiency even under varying pressures, reducing energy waste. In wastewater treatment or chemical plants, this translates to lower operational costs.

3. Low Maintenance, Long Life

With fewer moving parts and minimal vibration, screw pumps wear down slower than alternatives. Properly maintained, they can run trouble-free for years—a big win for industries prioritizing uptime.

Common Applications

Oil & Gas: Transporting crude oil or drilling mud.

- Marine: Fuel transfer and ballast water handling.

- Food/Beverage: Pumping syrups, dough, or dairy without contamination.

- Wastewater: Moving sludge with minimal clogging.

A Few Considerations

While screw pumps are robust, they aren't universal. Initial costs can be higher than centrifugal pumps, and abrasive fluids may accelerate wear. However, for high-viscosity or precision flow tasks, their benefits far outweigh the drawbacks.

Summary

Screw pumps are the essential part of fluid dynamics—quiet, dependable, and remarkably adaptable. As technology advances, their designs continue to improve, ensuring they'll remain a cornerstone of industrial operations for years to come. Whether you're pumping molasses or motor oil, there's a good chance a single screw pump is doing the heavy lifting behind the scenes.

Company video

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

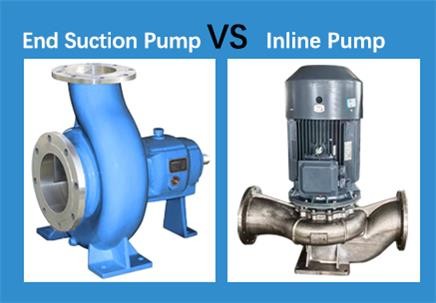

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

+86 28 8218 1182

-

+86 28 8218 1182