Learn - May. 16, 2025

Generally, a vertical pump is a type of centrifugal pump with the vertical shaft arrangement, which is designed for the limited floor spaces where require a pump to intake liquid up from tanks or deep wells. These vertical pumps are in different kinds of shapes, sizes, materials and with particular functions, but they all have one thing in common: Vertical and upright design to pump the liquid straight up through the discharge pipe. The vertical pumps can be made from PFA, FEP, stainless steel, Titanium alloy, Monel, Hastelloy...Due to the customizable material of construction as well as the sealing plan, those vertical centrifugal pumps, they are suitable for conveying high temperature fluids, corrosive chemical solutions or flammable fluids. Therefore, the vertical pumps can be used as vertical chemical centrifugal pumps, wet-pit pumps, sump pumps, vertical submerged pumps...

The vertical pumps are mainly designed as vertical shaft arrangement (including the vertical motor and vertical pump shaft assembly) to reduce the required floor space while efficiently conveying the fluids. The essential pump parts are as follow:

-Electric Motor: Normally mounted on the top of a vertical centrifugal pump to dive the pump.

-Pump Base Plate: A steel plate from where the vertical pump is mounted onto the floor, the proper mounting is the precondition of smooth operation of pump.

-Pump Shaft: A vertical and long spindle connecting the impeller and motor by couplings, must be fixed and supported by intermediate bearings when its length exceeds a certain value.

-Pump Impeller(s): Can be single stage or multi-stage, and located at the bottom of the vertical pump, creating the centrifugal force towards the fluid by the rotating blades to push the fluid upward.

-Pump casing: In which the impeller(s) is installed, converting the kinetic energy (created by the impeller) into pressure.

-Column Pipe: In which the pump shaft and intermediate bearings are installed, guiding the fluid upward to the pump discharge nozzle.

-Bearings Bushings: To fix and support the rotating shaft to reduce the wear of shaft and reduce the pump vibration, especially for long shaft pumps.

-Shaft sealing: To prevent the leakage from the pump shaft, can be either packing seal or mechanical seal, totally depends on the characteristic of the pumping fluid.

Vertical Centrifugal Pump: This type of pump is manufactured to handle harsh, corrosive fluids in jobs like waste treatment, draining sumps, moving liquids between tanks, mixing, wet processes, and other industrial uses. It works by turning spinning energy (from an engine or electric motor) into fluid flow energy. Here's how it works: The fluid comes in along the center of a fast-spinning impeller. As the impeller is rotating, it flings the fluid outward using centrifugal force, speeding it up and creating pressure. Next step, the pump casing then helps to guide and control the fluid, slowing it down a bit before sending it out the discharge, in this way, everything is moving smoothly and efficiently in the pump.

Vertical Submersible Pump: Also known as submersible pump and deep well pump, is a vertical hermetically sealed centrifugal pump with its motor shaft and pump shaft are directly coupled. Such submersible pumps share the same working principle with other centrifugal pumps, however, the only difference is its capability of working in the water. Most people mainly use those pumps when they need to move liquid from way down deep, like in a deep well or in sewage systems. What makes it special? Instead of sucking water up, it pushes water to the surface from the bottom. Furthermore, since it is installed deep underground or underwater, people even can not notice its noise during the operation of such submersible pumps.

Vertical Turbine Pump: Also be famous as the vertical long shaft multistage pump, vertical spindle pump or vertical line shaft pump. Basically, it is a type of centrifugal pump widely used to intake water from wet pits or deep wells when the capacity or discharge head of submersible pumps can not mee the required values. Due to the feature of higher pressure and big capacity, the vertical turbine pumps are widely used as high-pressure pumps, big flow rate circulation pumps, dry dock pumps, wet pit pumps... The common structure of such pumps is the design of an electric motor on the top, a discharge elbow, pipe columns, a long shaft running down the middle, and a series of pump casings and impellers at the bottom to push the water up through the pump column.

Vertical Sump Pump: Also known as the vertical submerged pump or semi-submersible pump for wet pits, sumps or tanks, it is simply a vertical single stage and single suction centrifugal pump with a separate discharge pipe even if it has a column just like the vertical axial flow pumps and vertical turbine pumps. There are various materials available for such pumps, including stainless steel, Titanium alloy, Monel, Hastelloy...Due to its excellent high temperature resistant performance and sealing performance, such pump are suitable for corrosive chemical solutions, therefore can be used as vertical high temperature sulfuric acid pumps and vertical molten salt pumps.

Vertical Axial Flow Pump: A vertical axial flow pump is a pump device that uses a propeller type of impeller to create large flow rate at low pressure to lift the fluid upward in the pump column. The main parts of such vertical propeller pump including a vertical electric motor or a diesel engine, an elbow pipe as the discharge nozzle, a long pump shaft that connecting the propeller and motor, a pump column pipe in which the pump shaft and bearings are installed, a propeller that generate the flow rate and pressure, a pump casing that converting the kinetic energy to pressure. Due to the feature of large capacity and low head, the vertical axial flow pumps are widely used as irrigation pumps, flood control pumps, drainage pumps, cooling water pumps, seawater desalination pumps...

Vertical Mixed Flow Pump: A vertical mixed flow pump is a multi-functional pump device which is the combination of both centrifugal radial pumps and axial flow pumps. Compared to the axial flow pump, the vertical mixed flow pump is able to create higher discharge pressure while maintaining the large flow rate (due to the special design of its impeller). Therefore, the vertical mixed flow pumps are suitable for applications that requires large flow rate at moderate discharge head (from 8 to 30 meters), due to this feature, they are the ideal choice for industrial cooling water circulation systems, municipal water supply projects, flood control pump stations, large-scale farm irrigation projects…

Vertical Multistage Pump: A vertical multistage pump is a centrifugal pump with multi-stage impellers tandem working with the same pump shaft in one pump casing. Due to this special structure, the pump is able to create higher pressure by gradually increasing the fluid’s energy from each stage of impeller. Furthermore, the pump discharge pressure can be customized by adopting different stage of impellers. Therefore, the vertical multi-stage pumps are suitable for applications requires high pressure but with limited floor space, therefore they are widely used as high-pressure water pumps, vertical boiler feed pumps, building water supply pumps...

Vertical Inline Pump: A vertical inline pump is a compact centrifugal pump of vertical structure with suction and discharge in the same line, compared to end suction pumps, the vertical inline pumps don’t change the direction of the pipelines. This special feature enables them to be widely adopted as HVAC pumps, boosting water pumps, circulation water pumps...

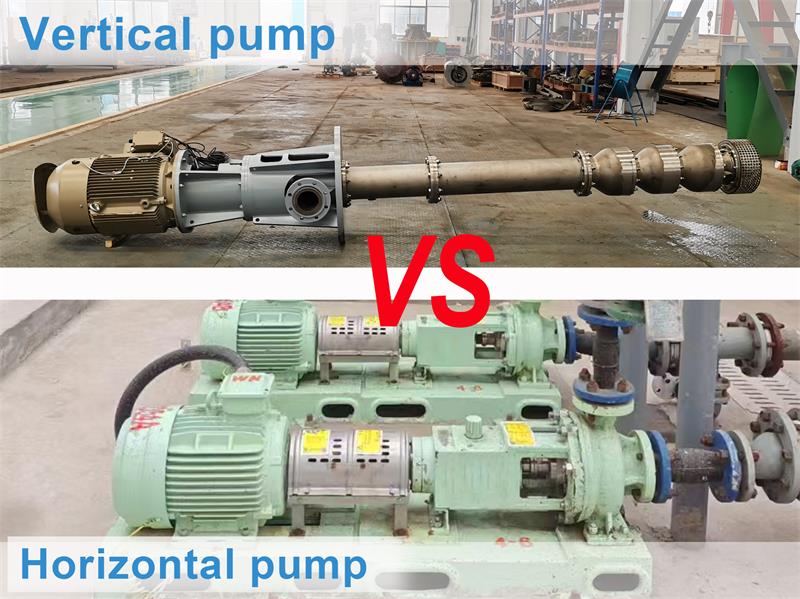

Structural differences: The essential difference between vertical pumps and horizontal pumps is the arrangement of the pump shaft. Most horizontal centrifugal pumps have a shaft that runs horizontally, and the common design for those horizontal pumps is the fixed shaft between bearings or as a cantilever design. On the other hand, vertical centrifugal pumps have a shaft that works straight up and down (vertically), typically designed as an overhung or radially split configuration. Which pump should you choose? Selecting the right pump depends on a few key things—like how easy the operation and maintenances will be, how much space you have at site, and what you need the pumps to do. So let's break down the advantages and disadvantages of those pumps for further analysis.

| No. | Item | Horizontal Centrifugal Pump | Vertical Centrifugal Pump |

| 1 | Shaft arrangement | Horizontal pump shaft | Vertical pump shaft |

| 2 | Space occupation | Takes more ground space, but requires less vertical space. | Takes more vertical space, but requires less ground space. (Suitable for limited floor space) |

| 3 | Flow rate & Working pressure | Large flow rate and moderate working pressure | Relatively smaller flow rate and lower working pressure |

| 4 | Working temperature | Can be high by working with suitable flush plans | Can be high for special vertical pumps like molten salt pumps and high temperature H2SO4 pumps |

| 5 | Pump efficiency & Power consumption | Lower power consumption due to high efficiency | Relatively higher power consumption due to lower efficiency |

| 6 | Priming before start | Required (except self-priming pumps) | Not required (Due to the pumps are working underwater) |

| 7 | Purchasing cost | Relatively low due to smaller size | Relatively high |

| 8 | Maintenance & its cost | Easy and cost low | Relatively difficult and cost high |

Working Principle: Both the vertical centrifugal pumps and horizontal centrifugal pumps share the same working principle - they use centrifugal force to accelerate liquid by an impeller and push the liquid out through its discharge pipe. Whether you choose the centrifugal pumps as horizontal or vertical, you'll find they can take good care of similar fluids like water, slurry, oil and various chemical solutions without issues.

Medium handling compatibility: Both the vertical and horizontal pumps are designed and manufactured for the purpose of conveying same characteristics mediums including water, sewage, slurry, oil, chemical solutions...

Material & Performance Options:

● Both type of pumps can be made from similar materials including cast iron, stainless steel, Titanium, Hastelloy...simply according to the medium characteristics.

● Based on the medium composition (e.g. corrosion or abrasion), both type of pumps can be adopted with different types of impellers including, closed impeller, semi-open impeller, open impeller, back open impeller…

● Both the vertical pump and horizontal pump share the similar shaft sealing methods and flush plans including packing seal, single mechanical seal, double mechanical seal

Hydraulic model compatibility: The fact is most horizontal and vertical centrifugal pumps share the similar hydraulic models, the differential performance is caused by the limitation of the pump structures.

Driving methods: Both type of pumps can be driven by electric motor or diesel engine

Industrial application similarity: Due to the similar performance, both the vertical centrifugal pump and horizontal centrifugal pump can be used as chemical centrifugal pumps, centrifugal water pumps, booster pumps, circulation pumps, sewage pumps...

Contact us now: sales@zgpumpvalve.com or wa.me(Whatsapp: +8613738006567)

Visit our workshops by VR Tour

What Are the Water Filling Methods for Centrifugal Pumps(Part 4)?

What Is A Single Screw Pump? What Is A Progressing Cavity Pump?

Application of MVR in salt wastewater treatment, achieve ZLD

Guide To Selecting The Right Slurry Pump For Your Application

Application of Diagonal Flow Pumps in Water Conservancy Project