Learn - Jun. 16, 2025

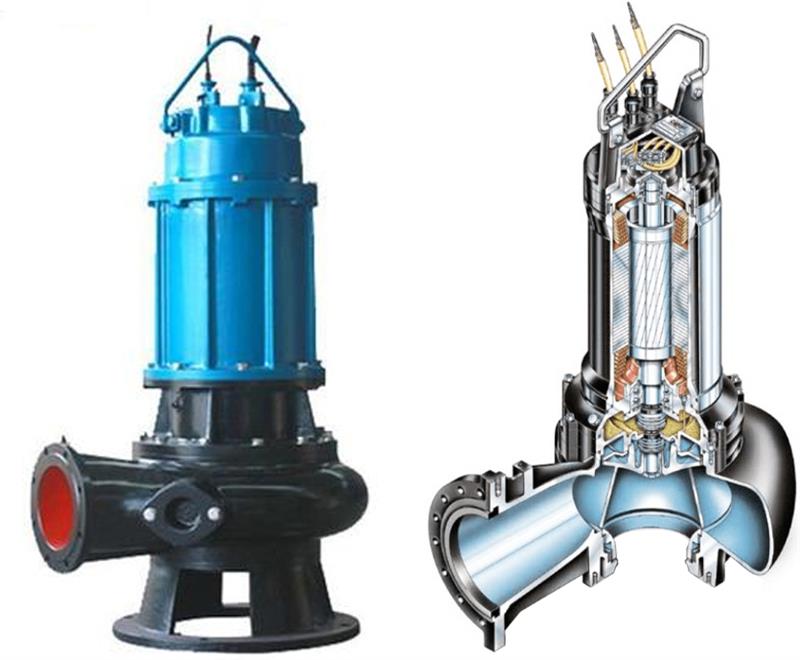

Submersible Water Pump is the pumping device that are working under water to convey wastewater that contains solids, particles, wastes, chemical solutions and all sorts of debris. What makes them special is that they work while completely immersed into the flood water, sewage, waste water tank or septic tank. This design enables them to pump wastewater effectively to either a sewer system or water treatment plants. Therefore, the submersible water pumps are more powerful than standard self-priming pumps, which is why they're the first choice for sewage removal and flood drainage jobs.

Submersible sewage pumps are absolutely the essential and ideal device to convey the waste water from various places including industrial and municipal facilities. They work hard continuously to move sewage where it needs to go. But just like any other equipment that gets heavy use, small problems would happen after long time operation. In this guide, we're going to go through the most common issues these pumps face, show you how to spot trouble earlier, and give you practical solutions to keep your submersible septic tank pumps working smoothly and so extend their lifespan.

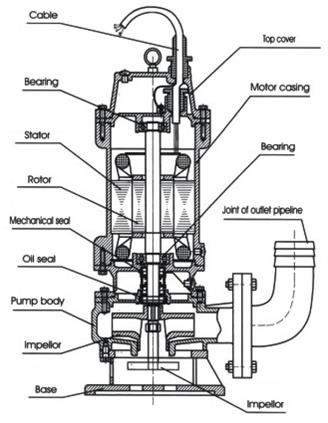

Clogging and Jamming: Obviously, this is the biggest headache for these sewage pumps. When solids, particles, debris, or random objects get stuck in the impeller passage, pump casing or even the discharge pipe, it's bad news that the pump's flow rate and pressure will go down, or worse - it stops working entirely.

Electric Motor Trouble: The motor is the power source of the pump, and when it fails, you're in some real troubles. Electrical issues, overheating, or just plain old wear and tear can make a motor out of good condition.

Float Switch Failures: This small device is designed to turn the submersible slurry pump on when sewage levels get too high. But when it stops working properly, you might get sewage overflowing or the pump working nonstop - neither of which is good.

Motor Overheating Issues: These pumps rely on being submerged in water for reducing the motor temperature. If the water level drops too low to immerse the pump, then the motor temperature gets higher than usual, and the overheating motor might shut down unexpectedly or just not work as well as it should.

Mechanical Seal Failure: Whether it's from seal failure or damage to the pump housing, leakages are bad news. They don't just make the pump less effective - they can create electrical hazards and contaminate the area around the pump.

Start Failure: Nothing's more frustrating than a pump that won't turn on. This could be due to electrical problems, motor issues, or control system failures. Figuring out the root cause is key to getting things working again.

Abnormal Noises: If your submersible slurry pump starts making weird sounds - grinding, screeching, or anything out of the ordinary – then it must be shut down for maintenance. These noises often mean there's debris stuck somewhere, parts have come loose, or the motor's in trouble.

Insufficient Water Flow: When the submersible well water pump isn't moving as much water as it should, something's definitely wrong. This could be due to clogs, wear and tear, or problems with the impeller.

Power Problems: Voltage fluctuations, electrical surges, or bad wiring can all affect your pump's performance. Inconsistent power might damage the motor or keep the pump from running at full capacity.

Maintenance Issues: Putting off routine maintenance would endanger the pumps. Without proper cleaning and inspections, troubles are following-clogs, motor issues, and a shorter lifespan for your pump.

Submersible pool pump troubleshooting is important, to prevent the pumps from potential failures, some necessary inspections must be done from time to time, and here's the check list:

Give It a Visual Check

Take a good look at the pump and the area around it. Check for obvious damage, leaks, or piles of debris. Look for cracks, rust spots, or anything that seems loose.

Intensive Check on Performance

Pay attention to pump working condition regularly. Notice the flow rate, watch the water levels, and focus on any odd sounds when the pump is working. If something seems wrong, then you need to shut down the submersible water pump for maintenance check.

Electric Motor Check

Focus on any signal of overheating from the motor- like a burning smell or an abnormal high temperature of pump casing. Make sure all the electrical connections are tight and free from corrosion.

Test the Float Switch

Move the float switch up and down manually to make sure it's triggering the pump correctly. It should move freely without any obstructions.

Check for Leaks

Examine the pump casing, mechanical seals, and connections carefully to avoid any potential leakages. Watch for water pooling where it shouldn't be or damp spots that suggest leaks.

Now that you have clear understanding to the potential and possible failures and issues with the submersible water pumps, then manage the removal of faults will be much easier than imagined. Below list is all about how to solve these issues:

5.1 Removal of Clogs

● First things first - cut the power for safety.

● Carefully pull the pump out of the water pool, sewage or septic tank.

● Check the impeller, pump casing and discharge pipe for blockages.

● Remove any blockages like debris, clogs or accumulations by a hard brush.

● For tough remaining clogs, try a plumber's snake or even a high-pressure plunger pump.

● Assemble the pump parts back together for the test run of your submersible slurry pump.

5.2 Dealing with Motor Failure

● Cut the power off and lift the sewage pump up from the septic tank or sewage

● Look for obvious motor damage like burnt wires or locked-up shaft.

● If it seems repairable, check the pump manual or a contact our after sales engineers.

● If motor not repairable, please contact us for replacement.

● Couple the repaired or the new motor onto the submersible sewage pump and start the test run, watch out for any abnormal conditions.

5.3 Fixing Float Switch Issues

● Safety first – cut off the power before starting anything

● Find the float switch and check for any damage.

● Make sure it's aligned properly and moves up and down freely.

● Test it by moving it up and down manually.

● If it's broken, please contact the submersible pond pump manufacturer for replacement.

● Connect the power, and check if the new float switch is working all right.

5.4 Fix Pump Overheating

● Turn it off and remove the vertical submersible pump out of the tank.

● Check the sewage level - add more if it's too low.

● Clear any clog blocking the pump casing, impeller or discharge pipe.

● Clean the motor vents thoroughly if it is necessary.

● If it still overheats after the above steps have been done, contact your submersible untility pump supplier for solutions.

5.5 Solving Leakages

● Power off and lift the pump out of sewage.

● Check pump casing, mechanical seals, and flange connections.

● Contact submersible wastewater pump supplier for replacement of damaged seals or gaskets.

● Tighten up any loose pipe fittings.

● For broken pump casing, contact your immersion pump supplier.

● Re-assemble the pump and test for leaks after all steps have been done.

5.6 When the Pump Won't Start

You may try the below steps and tips if your submersible sump pump can not be started:

● First, check that power is reaching the pump.

● Make sure the control panel is set to "on."

● Check the power cables to avoid any damage or loose connections.

● Inspect the circuit breaker or fuse if the power is free from anything wrong.

● If all else fails, contact the after sales engineers of your submersible pumps.

5.7 Eliminating Abnormal Noises

It is always suggesting some potential conditions of your submersible water pump if there are abnormal noises from the pump itself, try to follow the below steps to solve the problems:

● Power down and lift the pump from the tank, deep well or sewage.

● Clean up the debris or accumulated particles in the impeller area if any

● Clean up the foreign stuffs in the pump casing if any

● Inspect the bearing condition and lubricate them if needed.

● Contact your pump supplier for professional help if the noises continue existing.

5.8 Improving Water Flow

● Try the below steps if your submersible pumps insufficient flow rate:

● Switch off the and remove the sewage pump from where it is installed.

● Check impeller, pump casing and discharge pipe to avoid any clogging.

● Replace worn out impeller by a new one from the spare kit.

● Restart the pump and check the flow rate by the flowmeter.

5.9 Solving Power Supply Issues

Consider the below steps if there are some unusual conditions with the power supply of your submersible sewer pump:

● Thoroughly inspect all electrical connections to avoid any disconnections or corrosions.

● Look for damaged power cables like worn condition

● Check voltage with a multimeter.

● Consider using surge protectors or stabilizers.

● For issues beyond your capabilities, please contact an electrician for help.

It is wise to set up a routine maintenance schedule of the submersible pumps to avoid the potential and regular issues, please consider the below suggestions:

● Regularly clean the pump including the impeller, casing and discharge pipe.

● Check impeller and seals to find out the worn conditions earlier.

● In time lubrication to bearings.

● Test the float switch from time to time

● Intensive observation to pump performance including flow rate, head, noise and vibration.

● Follow the pump manufacturer's maintenance manual for other issues.