Learn - Jun. 06, 2025

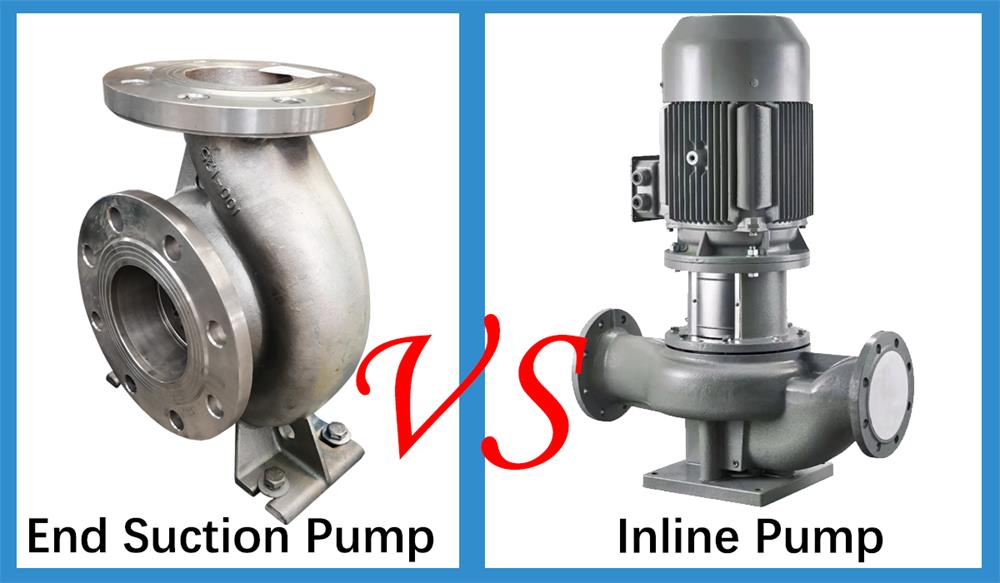

As one of the most common pumping devices, centrifugal pumps are suitable for conveying various fluids for farming, industries, chemicals, and city infrastructure. Out of all the different types of centrifugal pumps, end suction pumps and inline pumps are two of the most basic and widely used types—and each of them has its own advantages and features depending on what applications they are going to be used into. In this article, there are detailed breakdowns comparing the designs of these two pump types from every angle, giving mechanical engineers, maintenance managers, and buyers the essential knowledges they need before they make the right choice.

Here's the comparison list:

• How the end suction pumps and inline centrifugal pumps are designed and how they differently handle fluid flow

• The difference in mechanical setup and installation methods

• The difference of pump parameters in operation

• Maintenance notices and how long the pumps last

• Cost comparison over their entire lifespan

• The difference of applications between two pump types

• Pump efficiency

End Suction Pumps: Also called straight pumps, basically, they are single stage and single suction centrifugal pumps with cantilever impeller. What sets end suction pumps apart from other pump types is their unique L-shaped flow path. Its working principle: Firstly, the liquid flows in through a horizontal inlet at the end of the pump, that's why they're called "end suction" centrifugal pumps. Secondly, Inside the pump casing, the liquid takes a sharp 90° turn as it passes through the impeller. Finally, the liquid gets pushed out vertically through the discharge nozzle from the pump casing.

This unique design gives them some advantages as below:

• The sudden L-turn generates centrifugal force, boosting pumping power.

• They can fit larger impellers, making them more efficient.

• They work with different impeller styles (closed, open, semi-open, even recessed impellers).

• Multiple stacked impellers to gain high-pressure (multi-stage centrifugal pumps)

Inline Pumps: Vertical inline pumps have a straight flow path which enables the pump suction and discharge nozzles are to be in the same pipeline. Because of this unique design, they work a little differently than other pumps:

• They keep the flow smooth (laminar)

• Less energy lose since the fluid doesn't have to change direction much

• They usually have smaller impellers

• They're mostly single-stage (multi-stage type is available for special designs)

The way these pumps are built affects how they're installed and how they work. Let's find out what makes end suction pumps different:

End Suction Pump Design:

• The shaft arrangement is horizontal

• The impeller is overhung mounted (not between bearings)

• The pump and motor are separated and connected by the couplings

• It's foot-mounted, so it needs a solid base plate

• The pump is back pull-out design for convenient maintenance

Inline Pump Design:

• Most vertical inline pumps are monoblock structure, some special designs have couplings.

• No need for a foundation - the pipes hold it in place

• Super space-saving on floor because of the vertical installation

• No rear pull-out design for most of the pumps due to monoblock design.

End Suction Pumps: The end suction pumps usually take up 20-60% more floor space compared to the inline pumps of the similar capacities. This is because of how the motor is horizontally assembled into the pump, therefore it needs for a solid foundation, extra room for pipe bends and valves to make sure there’s enough space for maintenance.

This design has some benefits—like easier alignment of shafts during installation, average weight distribution, and more flexibility when setting up the piping.

Inline Pumps: These compact vertical inline pumps are good choices when space is tight - like when you're upgrading equipment in packed plant rooms, using skid-mounted systems, working in tight HVAC mechanical rooms, or setting up mobile equipment.

Just keep in mind: Installation requires pipe stress analysis since the pump handles the piping load. So, the proper support hangers are required, and remember there's not much wiggle room for changing the piping layout in the future.

Flow Rates Comparison:

• End suction centrifugal pumps work from 1 to 6,000 m³/h

• Inline pumps are more modest, managing between 0.5 and 500 m³/h

Pressure Comparison:

• End suction models are really powerful -Even single stage pumps can manage up to 25 bar, and over 350 bar for multi-stage pumps.

• Inline pumps max. handle around less than 20 bar typically

Efficiency Comparison:

• End suction pumps usually have approximately 10% higher efficiency at peak performance point.

• But inline pumps actually do better when operating at lower flow rates (below 20% of their best efficiency point)

When it comes to NPSHr (Net Positive Suction Head required), end suction pumps have some clear advantages. They relatively have lower NPSHr values, handle suction better, and they even handle negative suction pressure well.

On the other hand, inline pumps need extra attention on this regard. Please double-check those NPSHa margins, might need special inducer impellers to reduce the NPSHr value, and they have strict requirements about how the suction piping is set up.

End suction pumps offer significant maintenance advantages:

• Full disassembly can be done without dismantle piping (due to back-pull out design).

• Convenient replacement of bearing and seal.

• Impeller inspection requires minimal effort

• Shaft alignment is easy and accessible

Inline pumps present certain maintenance challenges:

• Motor disassembly typically necessitates pipe disconnection

• Mechanical seal access is restricted due to limited space

• Bearing replacement procedures are more involved

• Shaft alignment proves more difficult

End suction centrifugal pumps typically last between 20,000 to 60,000 operating hours, while inline pumps usually run for 10,000 to 20,000 hours before maintenance is required.

A few key factors affect reliability: bearing life (end suction pumps tend to have longer life due to the increased quantity and better arrangement of bearings), seal life (which depends on the pumping liquid features), and shaft deflection characteristics.

Water & Wastewater Applications: These pumps work well for raw water intake, booster stations, filter backwash, and moving sludge.

Industrial Applications: They're a good fit for cooling tower circulation, transferring process chemicals, boiler feed systems, and pumping high temperature fluids.

Other Applications: They also handle tough jobs like mine dewatering, pumping paper stock, moving abrasive slurries, and dealing with high-temperature fluids.

HVAC Applications: Great for moving chilled water, condenser water, and heating system fluids. They're also an ideal choice for district energy networks.

Building Applications: Perfect for boosting water pressure in homes, running fire sprinkler systems, and keeping water features circulating smoothly.

Industrial Jobs: Ideal for jobs like neutral chemical transferring, water supply and cooling water circulation.

End suction pumps have some clear advantages in the aspect of efficiency. Those pumps can accommodate high-efficiency motors more easily, run at lower temperature during operation, and offer more flexibility with VFD control systems.

On the other hand, inline pumps have some limitations though. The compact and space-saving design sometimes leads to restrictions of motor selection, and they tend to run at higher temperature due to cooling design of bearings, and that is a reason why they often require specially designed motors.

End suction pump setups provide several efficiency benefits. You get more flexibility in impeller selection, better matching curves with your needs, and more control strategy options like VFD, V-belts driven, gear box driven...

Inline pumps bring their own advantages to pump package efficiency. They typically create less pipe friction loss due to non-changing direction of the pipe; therefore, they may require lower discharge head pressure, and generally operate closer to their best efficiency point (BEP).

When looking at the initial price cost of each type of pumps, end suction pumps typically cost 10-20% more than inline models at the procurement stage. However, inline pumps might seem cheaper initially, but they often need special fittings that can be needed during pump operation.

Installation of each pump type tells a similar story. End suction units require more cost on the foundations, driving up setup and labor. Inline pumps install more easily and cheaply, though you might need to budget for extra backup pipe fittings.

Maintenance cost: Lower maintenance cost is one of the advantages of end suction pumps – they require very few maintenances due to the smooth operation, saving you on labor costs in the future days. Inline pumps on the other hand, often requiring more frequent repairs, as there is no bearing housing for most of the inline models.

Energy cost: End suction pumps are more efficient due to optimized hydraulic models, but they usually are coupled with bigger size motors, therefore, they are in fact more energy consuming. Meanwhile, the inline pumps have lower efficiency because of restricted arrangement of the pump casings, however, the motor power of inline models can not be as big as the end suction pumps, in this way, they always consume less energy.

Intelligent Technologies: Both types of pumps—whether end suction centrifugal pumps or inline pumps—are getting a high-tech upgrade. Nowadays, they are equipped with built-in sensors that monitor on vibration and temperature during the pump operation, IoT connectivity to forecast potential maintenance needs before the failures happen, and advanced motor controls that fine-tune efficiency. Basically, they're getting smarter and easier to control, and therefore become more reliable.

Material Upgrades: Innovations in materials is another reason that makes pumps last longer and operate better. We’re talking corrosion-resistant materials (including Titanium, Nickel, Monel, Hastelloy and even silicon carbide) that can handle harsh chemical solutions or abrasive fluids, well designed mechanical seal that enable leakage free operation, and even 3D-printed hydraulic parts that push the limits of design and performance. The future of pumping technology isn't just about fluid transportation—it's about doing it smarter, stronger, and with less downtime.

During the selection of pumps (both end suction type and inline type) for your applications, there are four essential notices to consider:

Firstly, think about what the pump needs to handle - the required flow rate, necessary pressure levels, and whether there is enough net positive suction head available (NPSHa). Kindly note the pump net positive suction head required (NPSHr) must be at least 0.5 m lower than NPSHa, otherwise cavitation would happen, causing abnormal vibration and noise, and therefore reduce the lifespan of pumps.

Secondly, consider where the pump will be installed - make sure there is enough space for the pump installation (get the pump GA drawing from your pump suppliers), matches your existing piping setup, and leaves enough room for the maintenance purpose.

Thirdly, check how the pump will be operated- will it run continuously or just intermittently? What kind of liquid is it handling? And how easy will it be to maintain? (depends on the characteristics of the pumping liquid)

Finally, don't forget the cost side - your initial budget (pump cost and motor cost), estimated operating costs (spare parts cost and power consuming cost), and the total cost over the pump's entire lifespan.

By fully understanding the above points, you are able to select the suitable pumps that match the requirements for your needs, and therefore avoid the unexpected failures.

Four Common Cooling Methods for Deep Well Submersible Pump(Part 1)

Application Of Evaporation Circulation Pump In Chlor-alkali Industry

What Are the Water Filling Methods for Centrifugal Pumps(Part 2)?

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

Application Of Mixed Flow Pump In Flue Gas Desulfurization (Part two)