Learn - Feb. 20, 2023

A liquid sulfur pump is a kind of vertical insulation pump specially for conveying molten sulfur (high temperature liquid sulfur), which is characterized by a long shaft, impeller and pump casing immersed in liquid sulfur. The temperature of liquid sulfur is between 135 and 145℃.

Liquid sulfur pumps are the key equipment widely used in the field of sulfur transportation. Vertical molten sulphur sum pumps are often used in chemical process. We are a professional manufacturer of liquid sulfur pump for the chemical industries, to meet requirements of the chemical plants for vertical submerged pumps, we produce high quality excellent performance molten sulfur pumps, which operate steadily, have long service life and competitive prices.

When the vertical molten sulphur pump starts at a lower level, it will not be difficult to start. The vertical liquid sulfur pumps from Zigong Pump & Valve at high temperature molten sulfur operate smoothly, and could ensure the lubrication of the bearings. As we all know, good lubrication could reduce sleeve and bushing wear, would have no strong vibration, could effectively extend the service life of pumps.

The repair process of a vertical submerged liquid sulfur pump is complicated and the maintenance cost is high. During the maintenance of a high temperature liquid sulfur pump, the pump must be lifted to the ground, remove the pipeline and components. After the maintenance, the pump must be immersed back into molten sulfur pit. This maintaining process takes a lot of time. An excellent design, high performance, stainless steel liquid sulfur pump could be operate smoothly, make sure the uninterrupted operation of the entire production line. That's very important for chemical plants.

Liquid sulfur is mixed with sulfur vapor, hydrogen sulfide, and sulfur dioxide, which are poisonous gases. In the maintenance process, the pump is lifted to the ground, and the liquid sulfur pit is in an open state. When the maintenance workers or engineers are working nearby, they could be harmed by these toxic gases.

We have over 60 years of experience in pump research and manufacturing; We have a Computational Fluid Dynamics Lab in partnership with Jiangsu University; We work on hydraulic optimization and materials application. At the same time we give everything to continuously improve our molten sulphur pumps by conducting ongoing research and using the cutting edge technologies. keep moving forward.

Liquid sulfur pumps are the structure of vertical long shaft centrifugal pumps, belong to the category of centrifugal pump. We perform hydraulic optimization on the flow parts (including impeller, volute, pump casing).

4.1.1 The number of impeller blades

The number of impeller blades has an effect on pump parameters, especially head, efficiency and cavitation performance. The choice of blade number, not only to consider as far as possible to reduce the blade extrusion coefficient and surface friction, but also to ensure that the length of the impeller flow channel is enough, so that the liquid in the flow channel by the full effect of the blade. The number of common blades is 5-7 pieces. The number of impeller pieces of the actual production of the liquid sulfur pumps should be determined according to the flow rate, head and working condition.

4.1.2 Blade outlet placement Angle ( β2) of the impeller

Blade outlet placement Angle (β2) is one of the important geometrical parameters of impeller, which affects the performance parameters, hydraulic efficiency and characteristic curve of pump. The commonly used blade outlet placement Angle ranges from 18° to 40°. In order to reduce the friction loss of the disc and improve the efficiency of the pump, the lower specific speed of the pump blade outlet placement Angle should be selected to be larger, in order to increase the head and reduce the impeller diameter. Thus, the disc friction loss is reduced and the pump efficiency is improved. But on the other hand, in order to obtain the descending characteristic curve, it is not appropriate to choose too large blade outlet Angle. In chemical plants, the most common vertical liquid sulfur pump impeller blade outlet placement Angle is 30°.

The rotor system of a molten sulfur pump consists of rotor ontology, bearings, bearing pedestal and couplings.

Based on the Workbench platform of ANSYS software system, the modal analysis of the rotor structure was carried out, through which the natural frequency and critical speed of the rotor structure were obtained, and the design was optimized to avoid the phenomenon of pump shaft resonance.

In the design and production process of a vertical submerged liquid sulfur pump, the shaft is particularly critical. According to the parameters of the working condition, design the pump shaft. Sometimes, If the depth of the pump is longer than 3 m, the coupling joint shafts design can be adopted to. The quality of the connection between two shafts is very important, which would directly affect the safety and reliability of the operation of the pump unit. Adopt rigid connection, stable and strengthen, and avoid large vibration.

The pump shaft is a three-support structure. The pump body is cast by wood grinding mold, and the impeller parts are cast by silica sol precision. Thus, make sure the inner surface of the impeller is smooth.

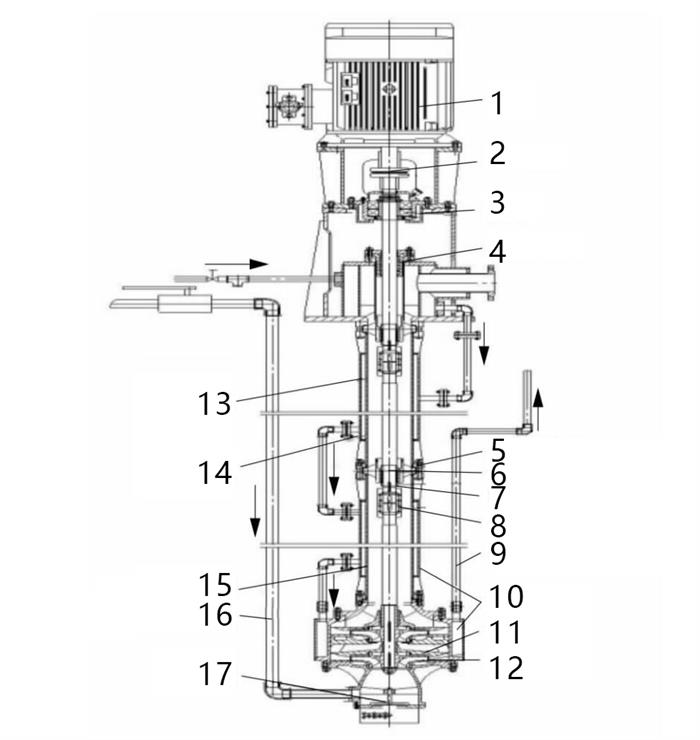

| 1.Motor | 2.Coupling | 3.Bearing | 4.Packing seal |

| 5.Guide bearing seat | 6.Guide bearing | 7.Shaft sleeve | 8.Coupling joint |

| 9.Heat conduction oil circulation pipeline | 10.Insulation jacket(steam jacket) | 11.Guide vane | 12.Impeller |

| 13.Upper support pipe | 14.Middle support pipe | 15.Lower support pipe | 16.Compressed air pipe |

| 17.Check valve |

This is a liquid sulfur pump, vertical suspension type centrifugal pump, two-stage impeller type, and impellers are immersed in the medium. The medium flows from the secondary impeller to the radial guide vane, and then discharges along the axial outlet. The upper part of the pump is provided with a diagonal contact ball bearing, and the part of immersing liquid is provided with 4 pairs of guide bearings. The pump shaft and outer shaft bushing are composed of multiple sections, and the intermediate drive shaft is connected by threaded couplings. This pump specification: flow rate: Q=100m3/h, Head: H=44m, Speed: n=1480r/min, Temperature: T: 135~145℃,Density: ρ=1960kg/m3.

Our customers demand maximum reliability, through raw material testing, flow parts, impeller, pump casing, shaft, inspection, make sure reliability. After casting, the main components of liquid sulfur pumps are subjected to non-destructive materials testing (such as liquid penetrant and ultrasonic testing). Surface crack, radiographic and ultrasonic testing ensure that the cast components are free from cracks and shrinkage cavities.

From the communicate with customers we do every day and end users feedback to our material experts, we know how materials behave under a wide variety of conditions and how to select them accordingly.

Highly wear-resistant white cast iron

Wear- and corrosion-resistant CrMo-alloyed white cast iron

Wear-resistant bainitic nickel-alloyed cast iron

Austenitic stainless steel

Corrosion and wear-resistant triplex stainless steel

Wear-resistant duplex stainless steel

Super duplex stainless steel

By finish-reading this article, readers may have some basical understanding of vertical molten sulfur pumps, which are the core pumping products for various chemical plants. With rich experiences in R&D of those equipment, we are able to manufacture high quality liquid sulphur pumps for our customers all over the world, we are always ready to provide tailored made pumping solutions for you.

Contact us now: sales@zgpumpvalve.com or wa.me(Whatsapp: +8613738006567)

Visit our workshops by VR Tour