Learn - Jul. 12, 2023

In the production, sales and comprehensive services of pumps, we attach great importance to service, including the design of fluid transport, pump installation and start-up guidance, pump aftersales and repairment, pump replacement projects, pump routine maintenance. We love to collect feedback from end-users and enjoy listening to customers’ comments about our pumps.

This is a pump tour from a paper making factory.

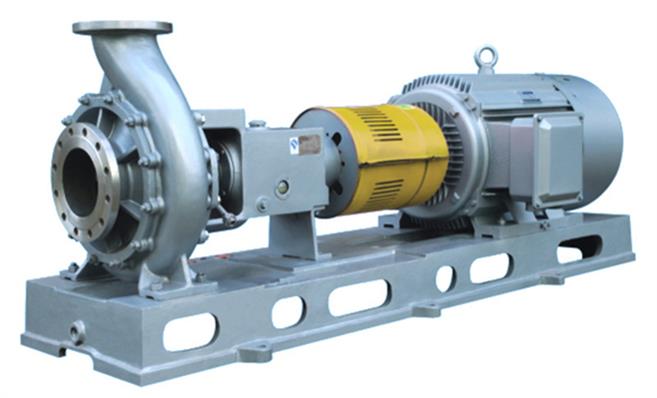

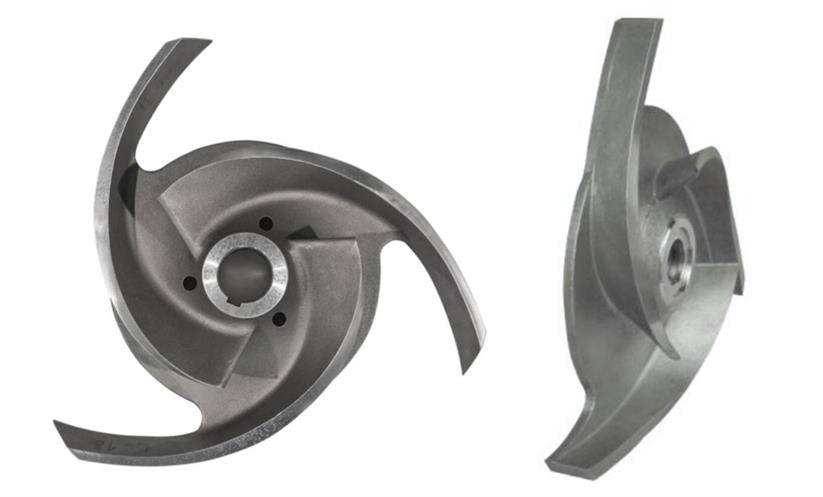

They are alkali pumps used in paper pulp making section, a total of forty titanium pumps, belong to open impeller centrifugal pulp pumps. Alkali pulp pumps made from titanium have a large flow path to allow the pulp to pass through, and have excellent corrosion resistance.

This batch of chemical centrifugal alkali pumps in the alkali making section has been running for more than ten years and still has been in good working condition. The end-user painted the pump (image 1 below) by himself, which was also conducive to preventing corrosion and rust on the surface of the pump, which is an anti-corrosion methods recognized by the chemical industry, so these titanium pumps look a little different than new ones (image 2 below). They don't look smooth and beautiful enough.

Pump engineers know that regular maintenance of chemical pumps can improve the efficiency and prolong the service life of pumps.

The first step is to change the lubricating oil.

Open the bottom of the tank of the alkali pump and drain the lubricating oil inside. Our chemical centrifugal process pumps are large space bearing boxes and oil pools. This is conducive to improving the overall rigidity of the pump, without the need for an external oil cup, reducing the temperature rise of the lubricating oil, and extending the life of the bearing.

Collect discharged waste oil.

All the waste oil is collected, then packed into waste oil drums, and finally disposed of centrally.

Add lubricating oil (hydraulic anti-wear oil ), just add to one-third of the tank level.

Wipe the oil and clean the pump outside, including cleaning the motor, baseplate and pump ground. Clean pump surrounding environment, is conducive to timely discovery of mechanical seal leakage, which is the chemical pump routine maintenance, is the simplest and most effective means. Keeping a clean environment around the pump is conducive to timely detection of whether the mechanical seal leaks, which is the simplest and most effective means of daily maintenance of chemical pumps.

Application of High-temperature Hot Water Circulation Pumps in Metallurgical Industry

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

How to extend the service life of chemical pumps - Maintenance of chemical pump properly

Application Of Mixed Flow Pump In Flue Gas Desulfurization (Part two)