Our multistage centrifugal pumps are especially designed and built for high-pressure applications, with a flow rate ranging from 3 to 846 m³/h and a head of 50 to 1450 meters. Those high pressure multi-stage pumps typically operates at 1450 or 2900 RPM, with power consumption between 0.5 and 500 kW and an efficiency of 60–85%.

■Flow rate: Q=3~846 m3/h

■Total head: H=50~1450 m

■Speed: n=1450rpm/2950rpm

■S.g.: γ ≤1.15

■Temperature: T=--20~160℃

■Pump diameter: 40~350mm

As a professional pump manufacturer, our multistage pumps have the features as below:

■Advanced hydraulic models with high efficiency and wide performance range.

■Smooth operation and low noise.

■Both packing seal and mechanical seal are available.

■Completely sealed shaft which is non-contact with fluid.

■The pump material can be changed to pump corrosive fluids. D(F) stands for a pump which is suitable for corrosive fluids, but its performance and is totally the same to D series.

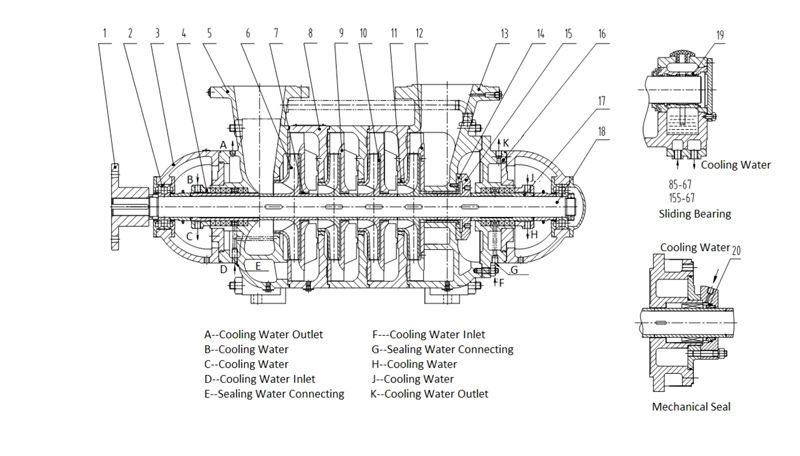

Thanks to the decades of experience on high pressure multistage pumps manufacturing, we optimized the structure of our centrifugal multistage pumps to achieve a better performance:

■The pump set mainly consists of bearing housing,inlet and out section,middle section,guide vanes.

■The pump inlet is horizontal and outlet is vertical;The balance hose on the inlet is connected back to the water inlet side.

■Between bearings structure.The rotary part consists of shaft,impellers and a balance disk.

■The gaps between pump inlet section,middle section and outlet section are smeared by molybdenum disulfide compound calcium-based lubricating grease as the sealings. The gaps of rotary part and static part are sealed seal rings,guide vane sleeve and packing.

■Standard shaft sealing is packing,can be customized as mechanical seal.

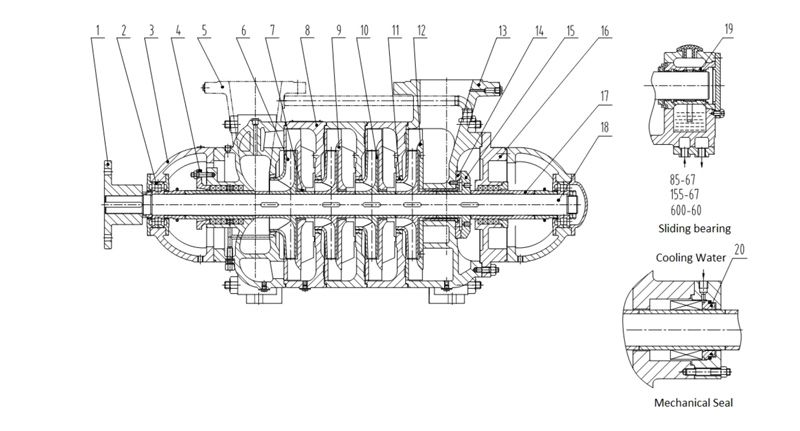

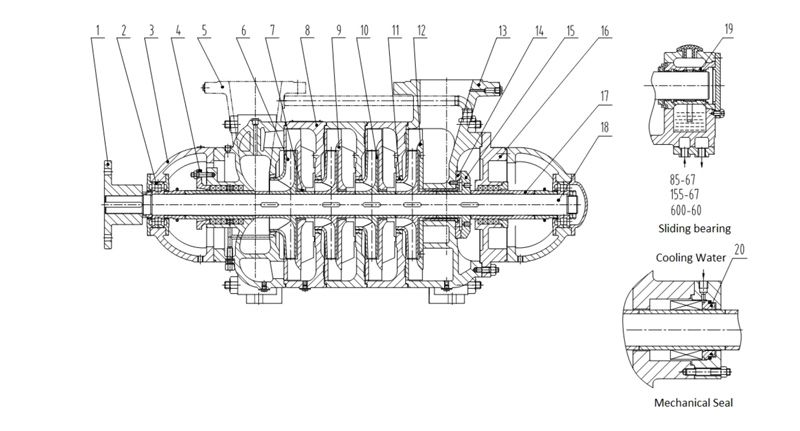

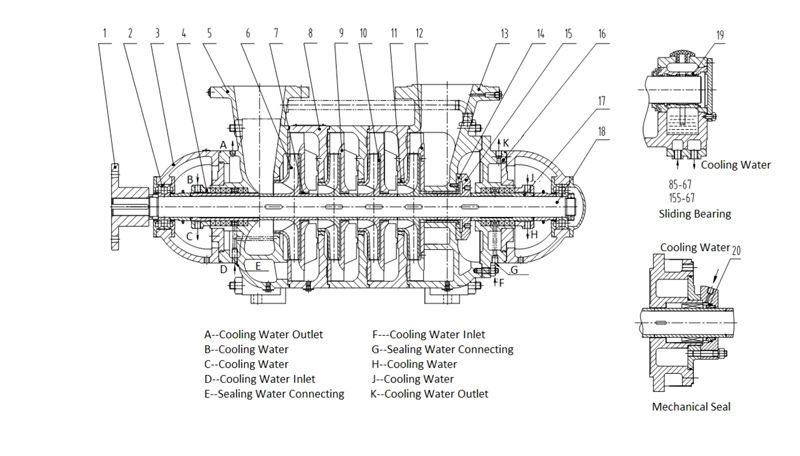

Structure drawing is as below

1. Coupling 2. Bearing 3. Bearing housing 4. Packing gland cover 5. Suction casing 6. First stage impeller 7. Diffuser sleeve

| 8. Stage casing 9. Diffuser 10. Impeller 11. Wear ring 12. Rear diffuser 13. Discharge casing 14. Balance ring | 15. Balance disk 16. Rear cover 17. Shaft sleeve 18. Shaft 19. Sliding bearing 20. Mechanical seal/Packing seal |

1. Coupling 2. Bearing 3. Bearing housing 4. Packing gland cover 5. Suction casing 6. First stage impeller 7. Diffuser sleeve | 8. Stage casing 9. Diffuser 10. Impeller 11. Wear ring 12. Rear diffuser 13. Discharge casing 14. Balance ring | 15. Balance disk 16. Rear cover 17. Shaft sleeve 18. Shaft 19. Sliding bearing 20. Mechanical seal/Packing seal |

To meet the various requirements from clients all over the world, we have different materials for our horizontal multistage centrifugal pumps as below, even Titanium multistage pumps are available:

| No. | Description | Material |

| Anti-corrosion alloy | Cast steel | Stainless steel |

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard |

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel

| Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205

|

| 2 | Sealing ring |

| 3 | Impeller |

| 4 | Pump cover |

| 5 | Impeller nut |

| 6 | Cartridge seal |

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 |

| 8 | Bearing Housing | Cast iron |

| Item | Factory standard | Optional configurations |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

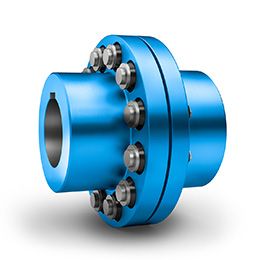

| Couplings |  | Pin type | Flexible diaphragm coupling |

■Widely used in mining, factories and city water supply and drainage.

■Suitable to pump clean water and fluids have close physical and chemical characters of water, or fluids like hot water, oils, corrosive material and particles.

■Widly used as the boiler feed water pumps for boiler systems