Learn - Apr. 12, 2023

People often have some kind of perception based on the past experience, for example, the sort of large devices tend to be slow, like a slow clunky piece of old equipment obsolete from the last century. In some chemical plants, like salt-making plants, you'll see these large devices —— horizontal chemical axial flow pumps. They're really slow, but they're efficient. Seems paradoxically. Then, we'll explain to you how to achieve a high efficiency horizontal axial flow pump at a relatively slow speed.

The brine extracts from the mine to make salt. The main equipment of this kind of salt-making plant is the circulating pump, which is used as the evaporation cycle to get the crystal of pure salt. The horizontal axial flow pump has large diameter to convey large flow, is the key equipment of forced circulation evaporation system. Sometimes, a horizontal axial flow pump is also called the forced circulation pump. Forced circulation axial flow pumps must have low speed technology. The reasons for being slow and efficient are:

1. The evaporation process requires the use of a slow speed horizontal axial flow pump, which is the basis of forced circulation evaporation process. The circumference speed of the impeller of our horizontal axial flow pump is controlled within 20m/s.

Salt making plant in the purchase of an axial flow pump, the impeller is required to destroy the crystal as little as possible, reduce the wear of the impeller, improve the NPSHr of the pump. A horizontal axial flow pump procurement tends to low speed and large diameter impeller. We are a long-term partner of the salt making industry. From the work we do every day and communication with salt making plants, our engineers found that serious cavitation occurred in the large axial flow pumps used by these salt factories in the past, because of the excessively high values of impeller circumferential velocity v and nD.

2. The forced circulating pump with low speed and large impeller diameter meets the special requirements of evaporative crystallization process.

3. In water projects, the axial flow pump is often used to pump large flow of water, and this kind of water axial flow pump uses aviation power airfoil. The inlet section of this type of airfoil is very thick, and the maximum thickness of the blade is close to the inlet, which is easy to deflow and has poor anti-cavitation performance. Chemical horizontal axial flow pumps are completely different, the maximum thickness of the blade of a chemical axial flow pump is in the middle of the chord, which corrosion resistance is excellent.

4. From the analysis of the boundary conditions of hub and rim, the hub rotates with the blade and has the tendency to drive the liquid to rotate and increase the circumference velocity. The inner wall of the pump at the rim is fixed, which has the effect of weakening liquid rotation. The reflux generated at the outer edge clearance reduces the axial surface velocity. Therefore, the axial flow pump in the design, should increase the hub of the axial surface speed. The design idea of variable ring quantity is: in order to reduce the placing Angle at the hub, the axial plane velocity and the circumferential velocity should be reduced here; In order to increase the placement Angle at the rim, the axial surface velocity and the circumferential velocity should be increased here.

5. Compared with the traditional design, the blade density of the outer edge airfoil is reduced appropriately, and the blade density of the shell airfoil is increased, so as to reduce the difference between the length of the inner and outer blade airfoil, reduce the secondary reflux under non-BEP conditions, and help to expand the usually narrow high efficiency zone and operation stability of the axial flow pump. The length of the airfoil near the outer edge is shortened appropriately, and the efficiency can be improved because the friction area is reduced.

6. Hub ratio is selected according to specific revolutions. The hub ratio of traditional design is small, the blade distortion degree is large, the deviation from the BEP working condition is father, the secondary reflux is more serious. Eventually, the efficiency decreases and the high efficiency zone narrows.

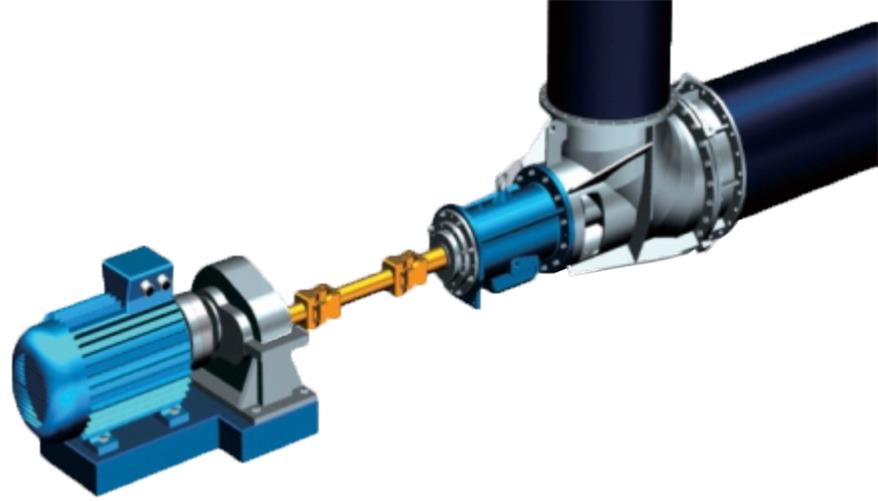

7. The large diameter horizontal axial flow pump is hanging in piping. Suspended pump avoids use of expansion joints. We recommend the cardan shaft with gearbox on separate baseplate required for motor with high dimensions and weight.

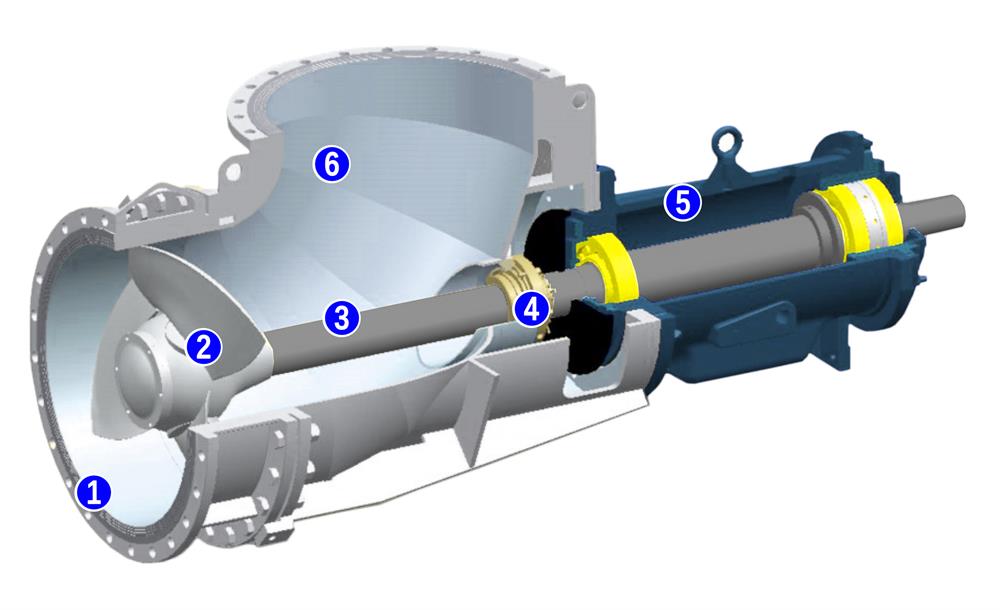

The pump body is an elbow type, and the main body is welded; The impeller is composed of a spherical hub and an adjustable blade. The seal adopts the static double - end mechanical seal. The front bearing of the pump is a centripetal short cylindrical roller bearing, and the rear bearing is a centripetal thrust roller bearing, which are lubricated by lubricating oil.

1. The pipe hung arrangement of axial flow pumps eliminate the problem of thermal expansion stress compensation of the system. The pump has no baseplate and no expansion joint, which saves the procurement and maintenance cost of the whole liquid equipment.

2. Precision casting, number milling processing and fine grinding ensure the blade profile is accurate. Pump material is dense and uniform. Optimized hydraulics with innovative impeller provides high efficiency, and make sure horizontal axial flow pump unit operates with low vibration, low noise and reliability.

3. The chemical horizontal axial flow pump equips with adjustable impeller to meet the requirements of evaporation system working conditions change in salt making industry.

4. The pre-assembled double-end static mechanical seal is standard and guarantees non-leakage and easy assembly.

5. Strong shaft and large bearing frame. The oil chamber of the bearing frame is large, and the bearing is lubricated well. All of this make sure the the service life of the axial flow pump is greatly extended.

6. Chemical horizontal axial flow pump is adopted slow speed technology. The damage to the crystal is small. And also has high efficiency and low NPSH.

7. The flow parts of the axial flow pump could be selected from a wide range of materials to meet the requirements of a variety of severe working conditions. Most of the forced circulation axial flow pumps used in salt making industry are made of stainless steel or duplex stainless steel. Titanium axial flow pumps are used in chlor-alkali industry for resisting corrosion. CD4MCu axial flow pumps are used in phosphoric acid industry, Monel axial flow pumps are used for evaporation circulation in calcium chloride. We have a materials testing lab. We understand how materials behave under a wide variety of conditions and how to apply them accordingly. We are continuously improving our materials’ corrosion resistance.