With a suspension frame, there is no need for a cooling case when transfer high temperature medium.

Its operating performance is improved by hydraulic model, Hastelloy isolation cover, and polished Impeller passage.

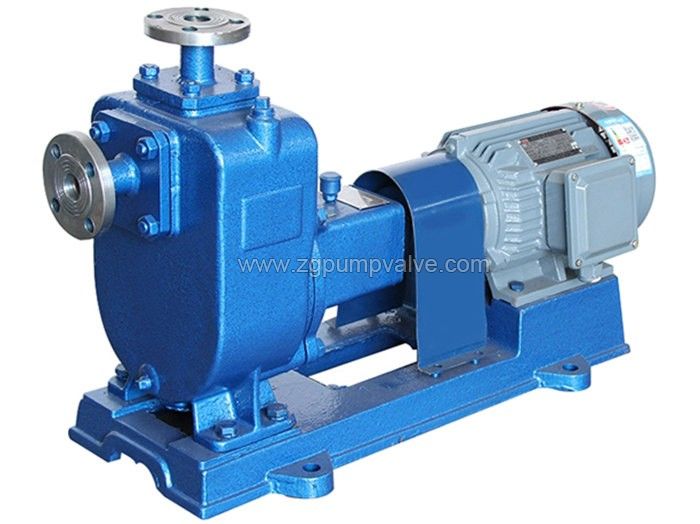

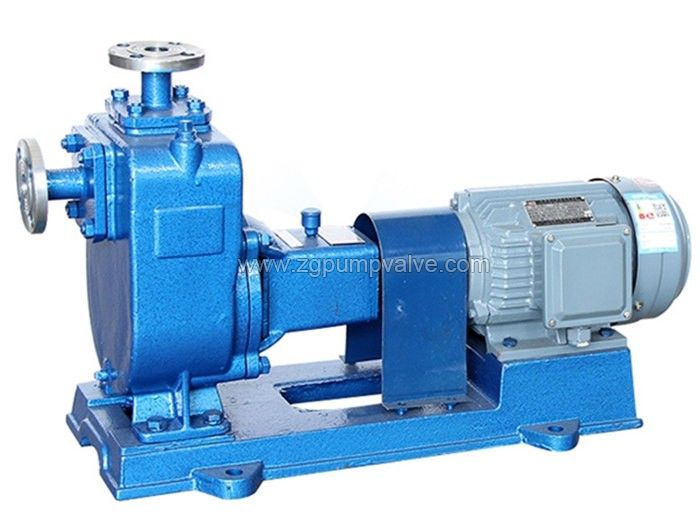

■Single stage,single suction,horizontal centrifugal pump. Bracket structure for bearing parts, the bearing housing is supported by the bracket. The axial displacement of pump rotor part can be adjusted by a special bolt. Closed impeller(ZBG type),semi-open impeller(ZBK type) and fully opened impeller(ZBQ type) are available.

■The impeller is connected with shaft by screw thread, an anti-vortex plate is adopted at the pump inlet to increase the reliability of pump.

■The impeller with rear blades is adopted to balance the axial force at the pump suction. And the gap between the rear blades of impeller and pump cover can be adjusted by a bolt.

■The pump structure is back pull type,the rotor part(impeller,shaft,shaft sealing and bearings) can be removed without dismantling the pipes during maintenance.

The shaft sealing is cartridge mechanical seal, and can be customized as single mechanical seal, packing sealing and secondary impeller+packing sealing.

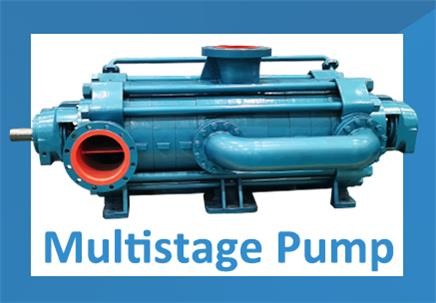

■Multiple evaporation and MVR evaporation process

■Refinery, petrochemical industries, coal chemical industries and low temperature projects

■Chemical industry, paper making industry, pulp industry, sugar making and other general process industries.

■Water plant, seawater desalinization

■Power plant

■Environment protection

■Vessel and at sea industries.