Learn - Nov. 21, 2020

At present, the centrifugal pulp pump that transports low-concentration (mass fraction less than 7%) pulp is mostly used in China. The medium consistency pulp pump's pulp conveying concentration (an abbreviation of the mass fraction) can reach 16%-18%, which can greatly reduce the number of pulp pumps used, thereby simplifying the entire pulping process, reducing water consumption and wastewater discharge. Therefore, medium consistency conveying technology is bound to become the trend of my country's paper industry.

Medium-consistency pulp is a three-phase gas-liquid-solid non-Newtonian fluid with very complex physical properties. This paper uses the sonar flow test system to build a medium-consistency pulp pump test bench that can measure the air content of pulp, obtain the air content of the pulp under different conditions, and then obtain the performance curve of the medium-consistency pulp pump, revealing the concentration, vacuum, The influence of speed on the characteristics of medium consistency pulp pumps provides test data reference for the design theory and operation of medium consistency pulp pumps, which has important guiding significance and engineering value.

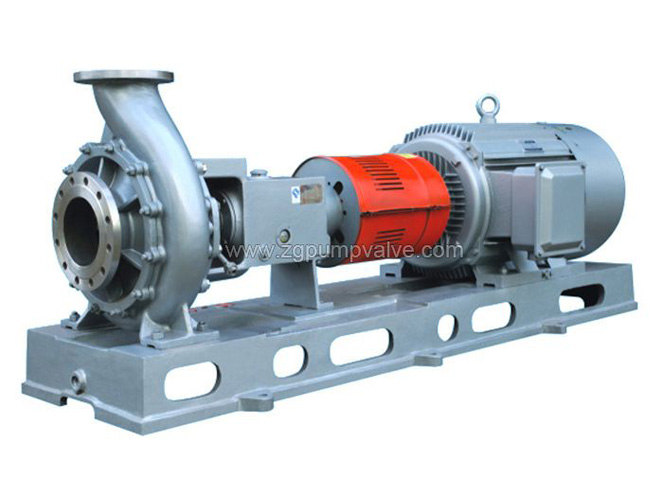

Compared with ordinary centrifugal pumps, it is equipped with a special device in front of the impeller to make the medium consistency pulp turbulent-a turbulence generator. Since the pulp contains a large amount of gas, if the gas in the pulp cannot be discharged in time, it will accumulate in the impeller, block the flow passage, and make the pump lose its conveying capacity. Therefore, the medium consistency pulp pump should also have the function of gas-liquid separation and corresponding discharge.气 structure. The gas in the pulp is separated for the first time after passing through the turbulence generator and gathered at the inlet of the impeller, and then passes through the exhaust hole on the impeller. Under the action of the back blade of the impeller, the gas moves to the vacuum chamber, and finally the gas is discharged through the exhaust hole.

When the concentration is 7.52%, the head has no obvious decreasing trend compared with clear water; however, the head drops significantly as the concentration continues to increase. The efficiency of the pump gradually decreases with the increase of the concentration; under the critical vacuum, the air content of the pulp in the outlet pipe of the pump is less than 1%; the air content of the pulp at the outlet of the pump increases with the increase of the flow rate.

When the pulp concentration reaches 12.1%, a large amount of gas will block the impeller flow path without vacuuming, causing the pump to quickly lose its conveying capacity; as the vacuum degree increases, the maximum flow that the pump can pump gradually increases.

The head increases with the increase of the pump speed, and the efficiency does not change significantly. As the rotation speed increases, the centrifugal force on the pulp increases, and the gas contained in the pulp is easier to separate. Therefore, the increase in rotation speed improves the gas-liquid separation capacity of the medium consistency pulp pump, thereby reducing the gas content of the pulp in the pump outlet.

As the flow rate increases, the required vacuum degree gradually increases, and the air content in the pulp increases but remains below 1%. Under the same pulp concentration, as the pump speed increases, the vacuum degree decreases, indicating that the increase of the pump speed is beneficial to the separation of gas and liquid in the pulp, thereby reducing the required suction vacuum.

In the test and measurement process, to ensure the normal operation of the pump, the vacuum level needs to be adjusted in real-time according to the change of the flow rate. The specific adjustment parameters are shown in Table 4. At the same rotation speed, the vacuum degree increases with the increase of the pulp concentration; as the rotation speed increases, the required vacuum degree decreases.

The above information is provided by the Tungsten pulp pump supplier.

The Difference between a Self-Priming Pump and a Centrifugal Pump

What Are the Water Filling Methods for Centrifugal Pumps(Part 2)?

Application of MVR in salt wastewater treatment, achieve ZLD

Guide To Selecting The Right Slurry Pump For Your Application

Why Choose Our Vertical High Temperature Liquid Sulfur Pumps?