Learn - Sep. 21, 2023

What efforts are being made to ensure providing premium pumps for pulp and paper industry?

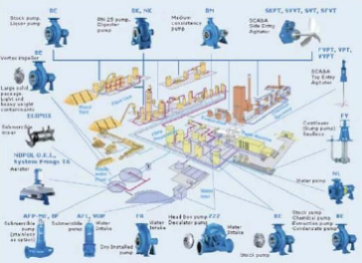

In modern pulp and paper plants, paper raw materials through cooking, washing, beating, sizing, manufacturing and other steps, a steady stream of paper products are produced. These fluid media, pulp fibers, black liquor, water, waste water, after pumping, evaporation, are distributed to different sections, pipelines, tanks, ponds. Different pumps play different functions in the papermaking process, which usually have water feed pumps, pulp pumps, vertical shaft line pumps, vacuum pumps, sewage sump pumps, etc. As the most critical dynamic equipment, pulp pumps are seemly tailored for the pulp and paper plant. They are widely used in all aspects of pulp transport and are crucial pumps in paper mills, which require the most quantities.

High efficiency open impeller pulp pumps ensure long-term steady operating, highly cost effective and long service time, and could meet requirements of papermaking enterprises to save procurement costs, save energy consumption, improve output, produce high quality paper and board products.

The manufacturing difficulty of pulp pump is to deal with the characteristics of pulp fiber. What efforts are being made for pulp pumps? We have carried out extensive research on the properties of pulp fibers and pulp suspensions in laboratories jointly established with the fluids department of the University.

Pulp suspension is a typical multiphase fluid of solid, liquid and gas, and its flow process is very complicated. Pulp suspension is a complex mixture of pulp fibers, air and water. The fiber particles in pulp are solid particles with a length much larger than the diameter. In the static phase of the suspension, the fiber particles will spontaneously tangle and coil to form the fiber network, and the pulp suspension has complex and diverse characteristics during the flow process. The fluid and fiber will affect each stage of the flow, and the fiber will also collide, intertwine and other phenomena. The irregular movement of the fiber leads to changes in the properties of the fluid, and the fiber will also be affected by the fluid and move constantly. Fiber suspension is a complex dynamic system. This needs to optimize the impeller and volute and other flow channels, pulp pump use open, semi-open centrifugal impeller, single and double flow channel impeller to achieve the purpose of anti-winding.

Pulp pump transport is a high corrosive solid liquid gas three-phase flow medium, the fluid has become a non-Newtonian fluid, the flow mechanism is complex, for the performance of the open impeller chemical process pump, including non-clog, no leakage, transport stability has higher requirements, in addition, but also the need for the flow parts of the pump has efficient hydraulic performance, corrosion resistance. In the processing of high-grade paper products, there are also strict requirements on the process parameters such as the uniformity of pulp, flow rate and pressure distribution. It is in response to these requirements that we manufacture high-performance pulp pumps, stainless steel open impeller large flow pulp pumps, or duplex stainless steel fully open impeller process pumps to meet the needs of the paper industry.

Our highly efficient pulp pumps benefit from a great amount of feedbacks from pulp and paper plants that have been long-term close co-operation. As a trusted pulp pump manufacturer, we stays close to customer with comprehensive services, professional material experts and competitive price.

As a full-line supplier, we also provide double suction split case water pumps for water and effluent treatment applications in pulp, paper and board industry. They are used as large flow water supply pumps in pulp and paper plants. Standard and customized large double suction split case pumps from us own low pulsation, high efficiency and long life cycle.

Wherever you are, you could get data sheets, technical support and professional services for the fluids transportation and chemical pumps from us as long as you have an Internet, a mobile phone, or WhatsApp. We make the procurement and configuration of chemical pumps conveniently.