Learn - Oct. 19, 2022

A vertical rotary jet pump is a new type of low flow high head high pressure, high efficiency and operation smoothly pump, which is different from the traditional centrifugal pumps. Compared with other pumps, roto jet pump has a unique rotating chamber, collecting pipe structure, its flow rate could be small, but can reach a high head. The vertical roto jet pump has many good features, which is why it is so popular with customers.

Each kind of pump has its own features, the structure of the pump determines its features, meanwhile the features of the pump determines its application field. Simply learn the features of roto-jet pump, could be good for selection pump, matching conditions better. These could maximize the advantages of roto jet pumps, to achieve smooth operation, to get high efficiency and low energy consumption, to extend long service life, to reduce maintenance.

Here we just list the seven main features of the roto jet pumps. Easy to read, and very useful.

1. Small flow, high head

The flow of rotary jet pump is small, but it can reach a very high head, its flow is generally a few cubic meters to dozens of cubic meters per hour, the corresponding head is dozens to thousands of meters. Now, the highest lift roto jet pump is RO type roto jet pump, lifting range up to 1858m, maximum flow rate up to 90m3/h, speed up to 6320r/min.

2. High efficiency

The pump internal energy loss is divided into three kinds: mechanical loss, hydraulic loss and volume loss. Mechanical losses are caused by seal, bearing and disc friction. For most low specific speed pumps, their disc friction loss accounts for about 25% of the pump input power. The key to improve the efficiency of low specific speed pump is to reduce the friction loss of the disc. However, in the roto jet pump, because of its special flow component structure - rotor cavity and impeller rotate with the pump shaft, only the small surface area of the collector is rubbed against the liquid, and this surface can be polished into a mirror. So the roto jet pump almost does not exist disk friction loss, mechanical loss is very small. The hydraulic loss of roto jet pump occurs in the flow parts from the inlet to the outlet, boundary layer separation and local resistance loss in the bend. The hydraulic loss of roto jet pump mainly comes from the collector tube. When the roto jet pump is used for low specific speed of small flow rate, high head working conditions, the efficiency is significantly higher than multistage centrifugal pump and other types of low specific revolution pump.

3. Smooth Q-H curve

In the roto jet pump chamber, liquid from the impeller into the rotating body flow smoothly, and no disc friction loss, so it can effectively avoid low specific speed centrifugal pump Q-H curve hump phenomenon. Roto jet pump flow smoothly, no pulsate when conveying liquid, conveying medium is stable.

4. Wide range of performance

The capacity and head of a roto jet pump can be easily adjusted. The flow rate of the roto jet pump is directly related to the diameter of the suction, and the head is directly related to the rotation speed of the pump shaft and the rotating body. Therefore, it is easy to change part of the structure or operating parameters of the pump, such as the size of the inlet of the collecting tube or the speed of the pump, in order to obtain different flow rate and head performance curves of the roto jet pump, to achieve a variety of different working conditions.

5. Full characteristics operation

The axial and radial loads of a roto jet pump are completely independent of the pump flow rate, which allows the pump to operate at any point along its operating curve without damage to bearings or shafts. Therefore, the roto jet pump from fully open to fully closed can run without damage.

6. Excellent sealing performance

The roto jet pump is only equipped with mechanical seal at the low pressure entrance, and the pressure at the entrance of a pump is generally not high, which is easy to seal. The high pressure outlet component is a static collector tube, so it can be static sealed without leakage. At the same time, because the roto jet pump speed is low, there is almost no axial force and unbalanced radial force, when the seal is damaged, the medium will not enter the bearing box.

7. Simple and reliable structure

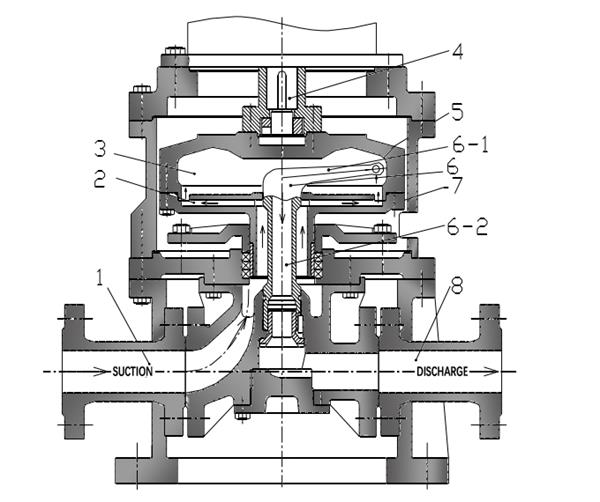

1.Suction tube 2.Impeller

3.Rotating chamber 4.Shaft

5.Upper pump cover 6.Collector

7.Lower pump cover 8.Discharge tube

6-1.Inlet section 6-2.Outlet section

According to the structure diagram of the roto jet pump, it can be seen that compared with the multistage pumps and high-speed pumps, the structure is simpler and the volume is smaller. The roto jet pump has very few rotating parts, and the sealing device is located in the low pressure area, so the roto jet pump is easy to maintain, has long service life.