Learn - Mar. 01, 2023

Part One :

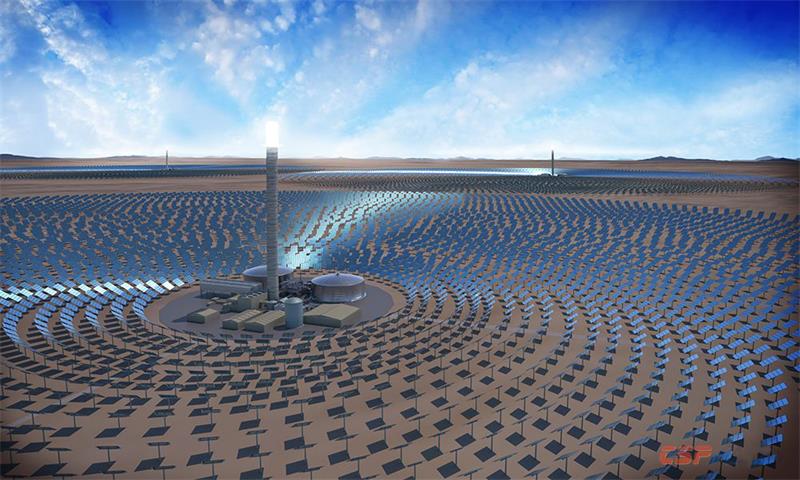

The healthy development of the global economy and human society is confronted with two major challenges: The first is the world energy crisis, and the second is the environmental problems caused by the burning of fossil fuels. The International Energy Agency (shorted as IEA) and many countries actively adjust the energy structure, and take renewable clean energy as the development objects, among the rest, solar energy is one of the most common new energy sources.

Nowadays, solar energy is mainly used in photovoltaic power generation and photothermal power generation. The latter one is also called concentrating solar power (shorted as CSP). The principle of CSP is to concentrate sunlight and convert the heat of high temperature fluid, and then through the way of thermal cycle to drive a generator to generate electricity. Compared with photovoltaic power generation technology, CSP avoids the expensive silicon photoelectric conversion process, could reduce the cost of solar power generation, could realize the power output "continuous, stable, controllable", is a green renewable energy technology with broad application prospects.

What can we do for clean renewable energy? What is our role in CSP?

Part Two :

In the heat transfer and storage system of CSP, the vertical high temperature molten salt pump, as the main circulating pump, is one of the most critical equipment in the heat island, which is responsible for the transmission of heat storage and heat transfer medium.

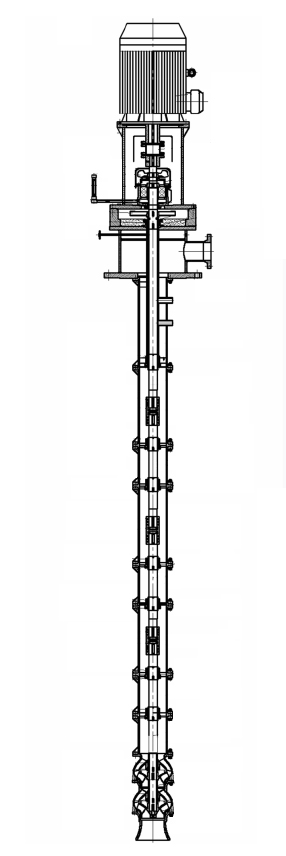

A high temperature molten salt pump for CSP is a kind of vertical long shaft pump, which is used for conveying molten salt at temperatures up to 400-700℃. As the main circulating pump in the CSP, its stability and reliability is one of the keys to ensure the safe operation of the heat transfer and storage system. The structure of this pump is vertical multistage.

Different from a hot salt pump used in the chemical industry, the high temperature molten salt pump used in CSP requires larger flow rate, higher head, and could withstand higher temperature. In some concentrating solar power plants, the liquid depth of a high temperature molten salt pump is even required to reach more than 16m. This means more efficient hydraulic design requirements, more slender pump shaft and more demanding stability requirements, more significant heat transfer, thermal expansion effect and reliability requirements of the upper bearing cooling system.

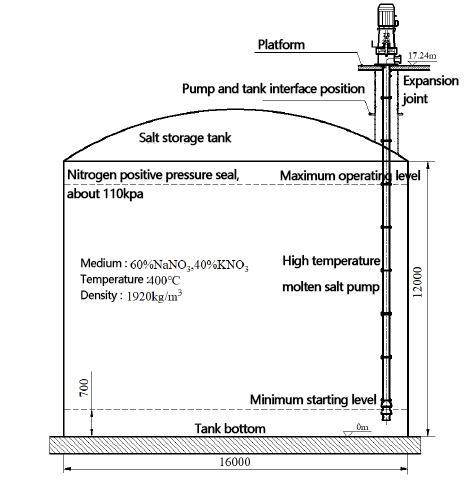

Sichuan Zigong Pump & Valve provided vertical high temperature molten salt pumps for a 100MW CSP in 2018. The parameters of the high temperature molten salt pump are: flow rate:790m3/h, head:48m, speed:1450r/min, the temperature of conveying molten salt is 400℃. In high temperature, large flow, high head conditions to meet the long-term, stable and efficient operation requirements. The optimal efficiency point of the pump is close to the operating point. The pump shaft is equipped with a sufficient number of radial bearings to provide near-rigid rotor construction. The first order critical speed of the pump and motor is 25% higher than the rated speed of the pump. The highest temperature of the upper bearing of the pump shall not exceed 80℃.

The molten salt pump is installed on a platform at the upper end of the salt storage tank, which is separate from the heat storage tank. The molten salt pump draws fluid from the bottom of the tank. The length of pump shaft is highly correlated with salt storage tank. The height of the salt storage tank is about 16m, the height below the pump bottom plate is about 17m, and the height of the whole pump is close to 19m(considering the height of the motor).

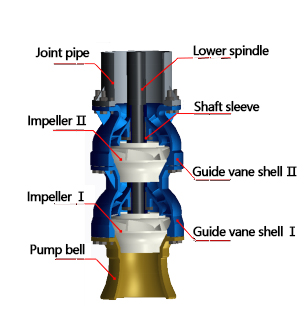

The high temperature molten salt pump adopts the VS1 structure conformed to API610-2010 standard. The discharge is located above the bottom plate and the motor is supported by the motor seat at the upper end of the pump. Because the whole pump is long, in order to ensure that there is no large transverse vibration, the design of the multistage nozzle and multistage pump shaft structure, the nozzle through the guide bearing body and the bolt connection, the pump shaft through the rigid clamp shell coupling connection. The lower end of the pump is the suction end, and the vertical pump usually has a bell shape to minimize the inlet loss. On the basis of hydraulic design, the structure of impeller and guide vane is optimized.

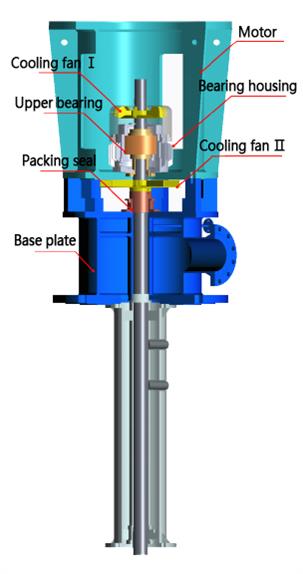

Shaft fans and efficient thermal barrier

Different from the high-temperature molten salt pump used in the general industry, a molten salt pump used in the concentrated solar power plant can reach a height of 16 meters under the liquid, and the ultra-long pump shaft is easy to cause rotor instability and vibration. On the basis of the bearing axial thrust, the upper bearing of a molten salt pump is also threatened by temperature rise caused by heat transfer of high temperature medium and high-speed friction, which makes the bearing heated expansion and lock in extreme cases, causing the failure of the whole system. Therefore, the design of the cooling system of the upper bearing is very important. Effective upper bearing cooling system reduces temperature, protect and increase lifetime of the pump bearings.

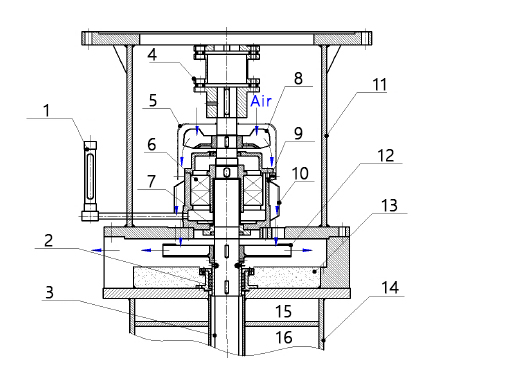

When a molten salt circulation pump is running, the temperature of the bearing box can not exceed 80℃, and the most effective method to control high temperature is forced convection heat transfer. For a vertical high temperature molten salt pump, there are three ways of bearing cooling: (1) traditional bearing water cooling system, (2) grease lubrication air cooling system, (3) double fans drive air to strengthen cooling of the upper bearings. The cooling system consists of: Front fan、Covering cylinder、Bearing box rib、Suction hole、Centrifugal fan、Thermal barrier、Nitrogen cooling system.

| 1.Oil level observation window | 2.Packing seal | 3.Upper pump shaft | 4.Coupling |

| 5.Cover | 6.Bearing | 7.Grease jacket | 8.Fan Ⅰ |

| 9.Bearing box | 10.Rib | 11.Motor seat | 12.Fan Ⅱ |

| 13.Thermal barrier | 14.Pump base | 15.Nitrogen cooling | 16.Liquid salt |

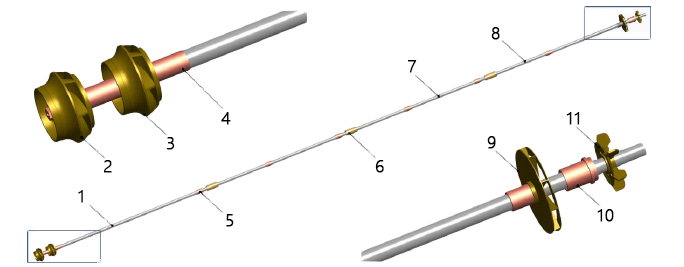

In order to easy dismantling and maintenance of a high temperature molten salt pump, the design of the pump shaft adopts a multi-stage core-pulling structure, equipped with replaceable shaft sleeves, which are fixed on the shaft through the keys. Every two joint shafts are connected to the sleeve by a clamp housing coupling, which shall be designed and fixed to ensure that the pump unit will not become loose when reversed. Considering the expansion of the pump shaft under thermal stress, the pump shaft is equipped with a sufficient number of radial guide bearings to improve the rigidity of the slender rotor structure. The rotor system consists of: main shaft、shaft sleeves、impellers、couplings、fans and so on.

| 1.Lower pump shaft | 2.Impeller Ⅰ | 3.Impeller Ⅱ | 4.Lower shaft sleeve | 5.Intermediate shaft sleeve | 6.Ribbed coupling |

7.Intermediate pump shaft | 8.Upper pump shaft | 9.Fan Ⅰ | 10.Bearing sleeve | 11.Fan Ⅱ |

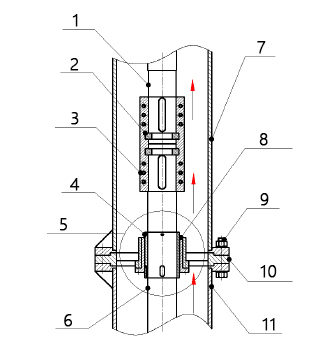

| 1.Upper pump shaft | 2.Cutting sleeve | 3.Ribbed coupling | 4.Shaft sleeve | 5.Guide bearing | 6.Lower pump shaft |

| 7.Joint pipe | 8.Throttle bush | 9.Bolt | 10.Guide bearing body | 11.Joint pipe |

The larger scale of an industrial equipment, the higher the demand for stability and reliability. The internal flow of a high temperature molten salt pump is complex, involving unsteady pressure pulsation and hydraulic excitation force, which requires high capacity of a pump manufacturer. We never stop exploring and optimizing the details and components of vertical high temperature molten salt pumps.

Impellers directly determine the transmission capacity of a molten salt circulation pump to the medium, and are the most core hydraulic components of a vertical pump. The guide vane collects the fluid from the first stage impeller outlet and transfers it to the entrance of the next stage impeller.

Hydraulic design of a guide vane: Space guide vane is one of the main parts of flow, which has important influence on the stability of flow. The structure of a guide vane is characterized by long axial direction and short radial direction. In the design, ①The wet circumference of the flow passage section is as small as possible, round or square; ② The shape of the flow passage changes smoothly, and the velocity of each section changes evenly.

Effective upper bearing cooling system, reliable rotor system and excellent hydraulic design make sure the vertical molten salt pumps have characteristics of high efficiency, low vibration, long lifetime and reliability as required for concentrating solar power plant.

To promote renewable energy, we always do our best. Solar power has great potential as a renewable and clean source of energy. We provide performance-critical vertical high temperature molten salt pumps for the operation of Concentrated Solar Power Plants.