Learn - Jul. 06, 2023

We know that chemical plants always exist those horrible and essential liquids, like hydrochloric acid, nitric acid, sulfuric acid, sodium hypochlorite, hydrogen peroxide, they are highly corrosive, if the material selection of device is not appropriate, that would corrode the equipment, resulting in the stop of the production line, equipment damage, and even the most serious personnel injury.

In chemical industry, when it is necessary to use axial flow pumps to transport strong acid or alkali corrosive liquid, the PFA lined axial flow pump is the ideal delivery equipment.

The common horizontal axial flow pump body is made of metal, if the transport is a strong acidic medium at ambient temperature, the metal material should at least choose titanium. Quite right, titanium has excellent corrosion resistance, but its price is too high. We select PFA lined axial flow pumps, can achieve the same effect, and the purchase price is very cheap. After a long-term use of PFA fluorine-lined axial flow pumps, feedback from chemical plant customers is very good.

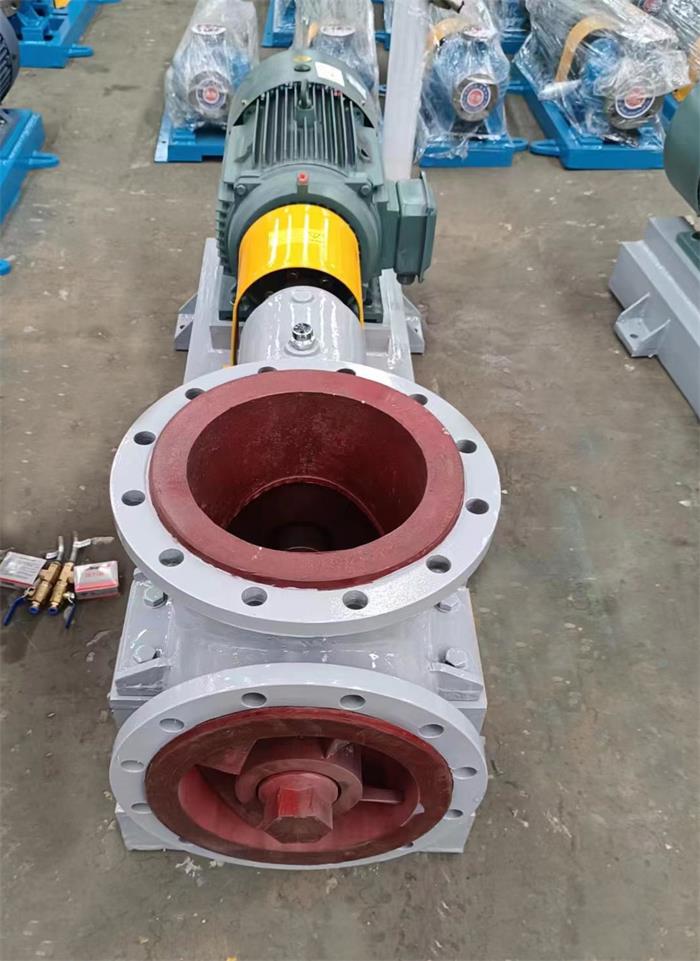

The fluorine plastic axial flow pump is the flow parts of the horizontal elbow axial flow pump lined with PFA to achieve the purpose of corrosion prevention, which is specially used for conveying strong corrosive medium such as strong acid and alkali at large capacity and low head.

For fluorine plastic lined axial flow pump, PFA, PTFE, FEP, PVDF, F46 can be selected as the lining material for hydrochloric acid, nitric acid, sulfuric acid, sodium hypochlorite, hydrogen peroxide and other highly corrosive liquid transportation. PFA stands for Polyfluoroalkoxy / perfluoroalkoxy / soluble polytetrafluoroethylene. PFA is a copolymer of a small amount of perfluoropropyl total vinyl ether and polytetrafluoroethylene. The fusion bond of PFA is strong, and it can withstand almost all solvents, and also can withstand high and low temperature environments. The lining material of the PFA protects the metal framework of the axial flow pump from corrosion.

PFA has the strongest corrosion resistance and can resist almost all the corrosion of strong acids, strong bases, strong oxidants, reducing agents and various organic solvents, and is the most used lining material.

PTFE lining metal mesh forming technology. The PTFE lined axial flow pump is composed of PTFE, metal mesh, fluorine plastic welding film, glass fiber, binder and metal skeleton, which has the characteristics of pressure resistance, high temperature resistance and strong alkali resistance.

PTFE lining composite molding technology. PTFE lining is tightly lined with metal components, which not only solves the problem of deformation and delamination of thermal expansion and cold contraction lining, but also withstands negative pressure. The use of heating cooling, charging, high temperature plasticizing technology, improve the density of PTFE, eliminate stress, lining performance is stable, under high temperature and high pressure negative pressure, can achieve the composite lining and metal skeleton. PTFE lined axial flow pump has good acid and alkali resistance, and is widely used in chemical, petrochemical, acid making, pharmaceutical and other industries.

We know that the horizontal axial flow pump is used for large flow rate, low head working conditions, usually its shape is a huge caliber, suspended hung on the pipeline, but this axial flow pump for highly corrosive liquids, its flow is relatively small, sometimes known as a small axial flow pump. The PFA lined axial flow pump is horizontal installation, pump and motor mounted on the same baseplate, direct transmission. Easy to install, good stability during operation.

PFA lining axial flow pumps could cope with severe working conditions of high temperature and high pressure, low temperature and negative pressure, chemical process temperature sudden change, and resist strong corrosive medium. We offer a comprehensive range of fluid transfer services to help you choose the most suitable pump for your condition. Our goal is smooth operation, no leakage and a long service life for chemical pumps.