Learn - Apr. 06, 2023

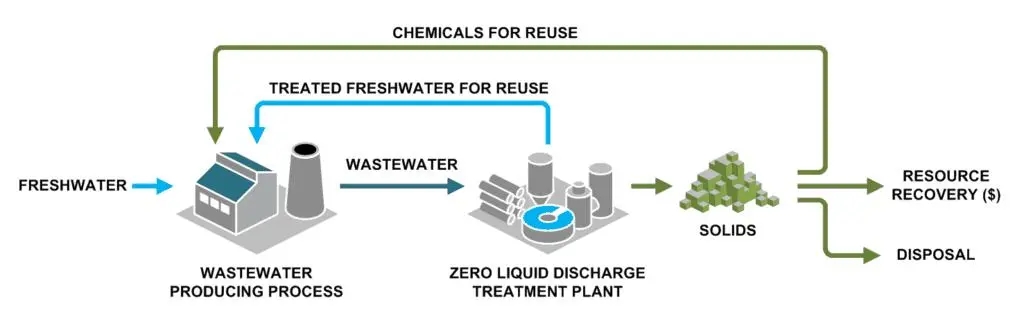

Nowadays we pay more and more attention to the protection of the environment, chemical plants are keeping progress and innovation. They become more Eco-friendly. The waste water produced by the chemical plant absolutely cannot be directly discharged into the nearby waters. It is required to achieve ZLD (Zero Liquid Discharge). The realization of ZLD can eliminate the problem of waste water discharge in chemical plants, recycle and reuse resources, and achieve environmental friendliness, green ecology and sustainable development. Achieving ZLD demonstrates good economics, corporate responsibility and environmental regulations. By operating an in-house ZLD plant, disposal costs can be reduced, more water is re-used, and fewer greenhouse gases are produced.

Nowadays we pay more and more attention to the protection of the environment, chemical plants are keeping progress and innovation. They become more Eco-friendly. The waste water produced by the chemical plant absolutely cannot be directly discharged into the nearby waters. It is required to achieve ZLD (Zero Liquid Discharge). The realization of ZLD can eliminate the problem of waste water discharge in chemical plants, recycle and reuse resources, and achieve environmental friendliness, green ecology and sustainable development. Achieving ZLD demonstrates good economics, corporate responsibility and environmental regulations. By operating an in-house ZLD plant, disposal costs can be reduced, more water is re-used, and fewer greenhouse gases are produced.

In the process of ZLD, there is an important step, is MVR technology. This article introduces the application of MVR technology in the field of salt wastewater treatment, which is very useful and simple.

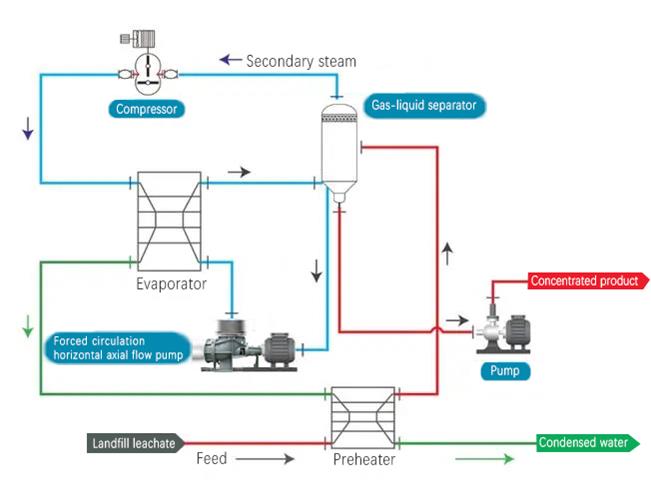

MVR is shorted for Mechanical Vapor Recompression. The core of MVR wastewater treatment technology is to use the latent heat of secondary steam generated by the system for heating, evaporation and recovery of water resources, to realize the recycling of heat.

It is a big challenge to treat salt wastewater ideally. There are many kinds of salt wastewater, its sources are extremely wide, the ingredients are also complex, a single treatment method can not get good results. The technology is difficult. In salt wastewater, the concentration of inorganic salts is very high, including sodium ions, chloride ions, calcium ions, potassium ions and sulfate ions, etc., the salt content is more than 1%.

There are several technologies for treating salt wastewater: biological treatment technology, membrane separation treatment technology, incineration treatment technology, cooling crystallization treatment technology and heating evaporation crystallization treatment technology. Specific analysis:

① Biological treatment, used to treat non-toxic salt wastewater, but if the wastewater contains salt-tolerant bacteria, the difficulty of treatment will increase;

② Incineration treatment, suitable for wastewater containing more organic matter, through incineration can also obtain salt solid;

③ Membrane desalination treatment, salt wastewater after treatment into fresh water, but the membrane has high requirements for the environment, water quality also has requirements, membrane needs to be replaced regularly, the amount of investment is large;

④Cooling crystallization technology is suitable for wastewater where the solubility of salt is affected by temperature, and the application field of this technology is too narrow;

⑤ Heating and evaporation technology, which can deal with any kind of salt, can deal with any concentration of salt, can separate salt substances, to achieve "zero emission" of salt substances.

Heating evaporation treatment is divided into multi-effect evaporation technology and MVR technology. The application of multi-effect evaporation technology requires a large amount of steam consumption and the use of cooling water, and the heat energy can not be recycled. Compared with multi-effect evaporation technology, MVR technology needn’t to consume a lot of energy, achieve "zero discharge" of salt wastewater, and recover resources, is an ideal industrial wastewater treatment technology.

Mechanical Vapor Recompression (MVR) is an energy-saving evaporative concentration technology that could reduce evaporation energy consumption by more than 90%. The whole MVR system only need equip a heating room, no condenser, and no cooling water. MVR technology has a wide range of application, and the cost of equipment is small, as well as the subsequent operation is stable.

The MVR system is mainly composed of heating room, crystallization part (separation part), forced circulation pump and compressor. Their profiles are as follows:

1. Heating room The heating room is a tubular heat exchanger, the tube is the material, the shell is steam, in the shell of the baffle will increase the heat transfer function with continuous disturbance, at this time the operation of the forced circulation axial flow pump, under the action of the material evaporation and circulation operation, the speed of the material flow increases, so as to avoid the problem of dirt condensation in the heat exchange tube.

2. Crystallization part (separation part) The crystallizing part is a vertical device. After the material enters into the device and evaporates, the steam and liquid are separated, the material is settled, and the crystal is precipitated.

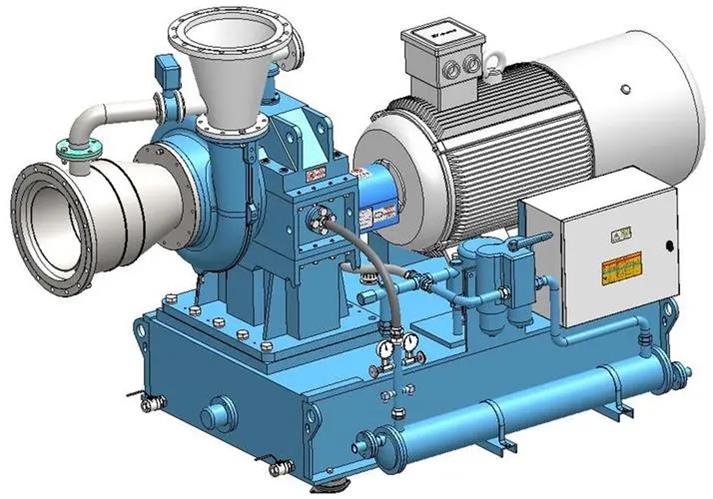

3. Forced circulation pump This circulation pump mainly adopts horizontal axial flow pump, which is suitable for large flow and low head condition. Horizontal axial flow elbow pump is very good. The large diameter horizontal axial flow forced circulation pump promotes the material flow rate in the evaporator to increase and prevents scaling in the tube. Because the flow rate is very large, it could effectively reduce the average supersaturation of the solution and promote the crystal growth. The forced circulation axial flow pump is the heart of the whole MVR system.

4. Compressor Compressors include the centrifugal compressor and Roots compressor. The centrifugal compressor is suitable for large evaporation operation, boiling point is not greatly increased. Roots compressor does not have a large amount of evaporation, the range of boiling point rise is relatively large. The compressor is selected according to the characteristics of the material liquid to be configured.

Saline wastewater is generated in almost all chemical production processes. When ZLD is come true, it recover inorganic salts in wastewater, produce economic benefits by by-products, and most importantly it is friendly to the environment and does not pollute the waters. We are committed to promoting the construction of MVR projects, and manufacture high performance horizontal axial flow pumps, which save energy and reduce cost. Our material experts use the right materials to ensure against corrosion and build a long-lasting MVR system.

The Difference between a Self-Priming Pump and a Centrifugal Pump

Correct Use and Maintenance Method of Acid and Alkali Resistant Magnetic Pump

Zigong Pump & Valve Co., Limited organize special training on equipment management and maintenance

What Are the Water Filling Methods for Centrifugal Pumps(Part 4)?