Fluorine Plastic Centrifugal Pump

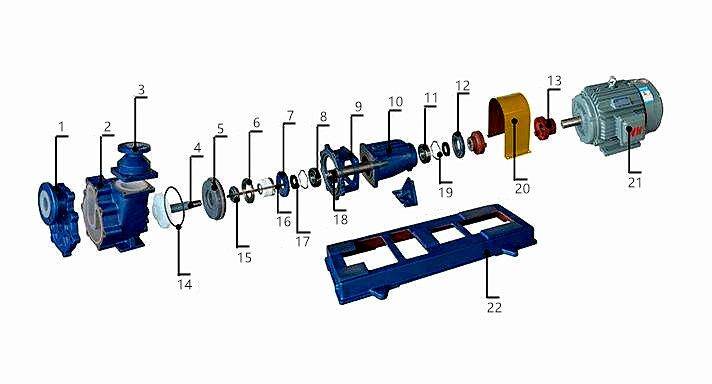

PTFE/PFA lined self-priming pump

The FZB series FFA/PTFE/FEP plastic self-priming pump is designed according to international standards and China National Standard. All flow components are lined with FFA/PTFE/FEP, and the load bearing part of the pump is made of metal. Can be equipped with external single-face mechanical seals, external container-type mechanical seals with flushing water, and can customize API682 standard flushing schemes. They are corrosion- and wear-resistant and can handle corrosive acids, aggressive liquids including hydrochloric acid(HCl), sulfuric acid(H2SO4), chromic acid, phosphoric acid, caustic soda (sodium hydroxide,NaOH), nitric acid...

■Flow rate: Q=3.6~100(m³/h)

■Total head: H=18~45 (m)

■Speed: n=2900rpm

■Self-priming height: 1~3 m

■Self-priming time: 150~250 s

■Temperature: T=-0~95℃