Axial Flow Pump

Horizontal Axial Flow Pump

The Horizontal Axial Flow Pump is designed for high-flow & low-head pumping needs where the space is sufficient and allows a horizontal piping system. Its axial flow structure enables the efficient transfer of large volume of fluids with minimal energy consumption, making it ideal for water circulation, irrigation, industrial cooling, and flood control. The pump's elbow flow path reduces hydraulic losses, meanwhile its accessible design simplifies maintenance jobs. The horizontal axial pump type offers reliable performance in continuous pumping applications and can be customized with various material options to suit the pumping fluids, providing a cost-effective solution for large-volume fluid transfer requirements.

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

The horizontal axial flow pumps are specially designed for vairous chemical plants where the big volume flow and low discharge pressure is required, such axial flow pumps have wide performance ranges that can cover the needs for most chemical manufacturers.

■ Flow rate: Q=300~18,000 (m³/h)

■ Total head: H= 1~6 (m)

■ Speed: n=180-1450rpm

■ Fluid temperature: T= 0~150℃

■ Fluid s.g.: γ≤1.4

The horizontal axial flow pump is the optimized pumping device which features high efficiency and reliable operation, below are some main features of those axial those axial flow pumps:

■ Propeller blades angle adjustable

■ Slow pump speed design to avoid cavitation

■ Low NPSHr value.

■ Pipe hung arrangment avaible

■ Propeller casing design, enables the quick dismantle of propeller.

■ Low vibration, high efficiency and energy-saving.

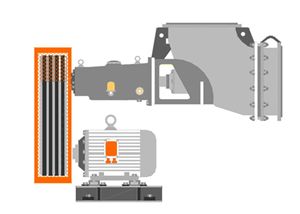

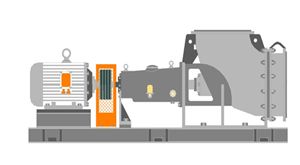

The horizontal axial flow pumps have a propeller-shape impeller installed in an elbow pump casing. The main pump parts including the suction casing, propeller, pump elbow, couplings, motor and base plate. With this compact design, making the horizontal axial flow pump ideal for big flow rate and low discharge applications like evaporation, irrigation, flood control, and large-scale water circulation.

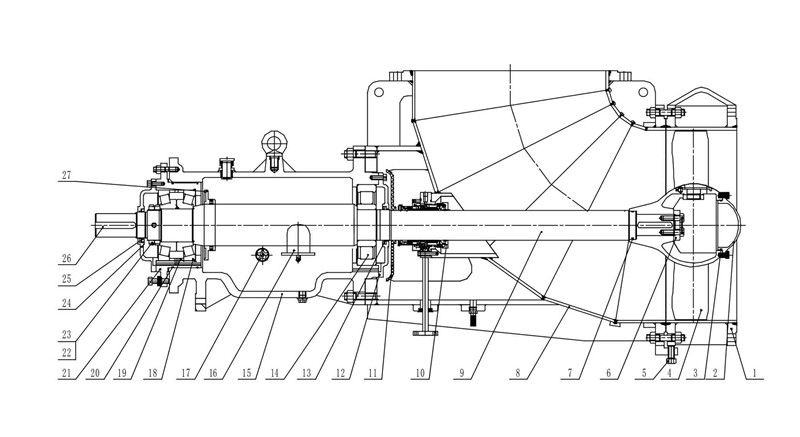

Structure drawing of horizontal axial flow pumps

1. Casing 2. Impeller hub cover 3. O-ring 4. Impeller 5. Adjust bolt 6. Gland plate 7. O-ring 8. Elbow 9. Shaft | 10. Catridge mechanical seal 11. Water retaining ring 12. Front bearing cover 13. Skeleton oil seal 14. Front bearing 15. Bearing housing 16. Oil level gauge 17. Oil leveler 18. Rear bearing | 19. Bearing spacer 20. O-ring 21. Bearing box 22. Lock nut 23. Retaining gasket 24. Rear bearing cover 25. Skeleton oil seal 26. Key 27. Oil flinger |

| K-pipe hung arrangement No baseplate for both pump and motor,no expansion joint on pipe. The Axial Flow Pump is driven by motor through V-belts.This arrangement is only applicable for the pump diameter from 300-500mm and motor capacity below 55Kw. |

| E-half pipe hung arrangement No baseplate for axial flow pump,pump is hung on the pipe,no expansion joint on pipe.For big axial pumps above 700mm diameter,there must be a fluctuating frame at the horizontal pipe connecting the pump.Only V-belts and universal joint are recommended as the transmission method for this arrangement. |

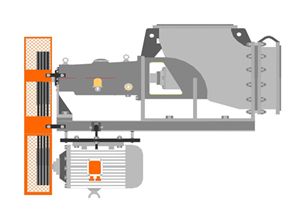

| F-horizontal arrangement Baseplate is required for both axial pump and electric motor. An expansion joint on the pipe is also required for high temperature applications.Transmission methods can be V-belts and direct coupled. |

For easy maintenance purpose,the above mentioned arrangements require a casing between horizontal pipe and the aixal flow pump. | |

Most of the axial flow pumps are made from stainless steels or duplex steel for corrosion resistance, as they are mainly installed in various chemical plants. Some special applications may use nickel alloys, Monel, Hastelloy or polymer-coated components for highly corrosive chemical handling. For example, Titanium Axial Flow Pumps are widely used in salt making industries. Below are the detail material constructions of our axial flow pumps:

| The name of material | The code name of materials | The name of spare parts | |||

| International standard | American standard | Impeller | Impeller cover | Pump body (with casing) | |

Corrosion resistant cast iron | Aluminum cast iron gray cast-iron nodular cast iron Cr28 Cr30 | C.I D.I | ● ● ● ● | ● ● ● ● | |

| Carbon steel | Q235-A 23 25 | A A36 WCA WCB | ● ● | ||

Stainless steel | (ZG)00Cr18Ni10 | CF-3(SS304L) | ● | ● | ● |

| (ZG)0Cr18Ni9 | CF-8(SS304) | ● | ● | ● | |

| (ZG)0Cr18Ni12Mo2Ti | CF-8M(SS316) | ● | ● | ● | |

| (ZG)00Cr17Ni14Mo2 | CF-3M(SS316L) | ● | ● | ● | |

| (ZG)0Cr18Ni9Ti | CD-4MCu | ● | ● | ● | |

| (ZG)1Cr18Ni9Ti | Monel | ● | ● | ● | |

| (ZG)1Cr18Ni12Mo2Ti | ● | ● | ● | ||

| NO.20 alloy | ● | ● | ● | ||

| 1Cr13 | ● | ● | ● | ||

Duplex Stainless steel | 0Cr26Ni5Mo2 | (AlSi)329 | ● | ● | ● |

| 0Cr17Mn13Mo2N | ● | ● | ● | ||

| 00Cr18Ni5Mo3Si2 | ● | ● | ● | ||

| Anti-corrosion alloy | TA1、TA2、TA3 | Monel | ● | ● | ● |

| TA9、TA9-1 | H-B | ● | ● | ● | |

| TA10 | H-C | ● | ● | ● | |

| Ni-Resist1 | ● | ● | ● | ||

| Ni-Resist2 | ● | ● | ● | ||

| Ni-Resist3 | ● | ● | ● | ||

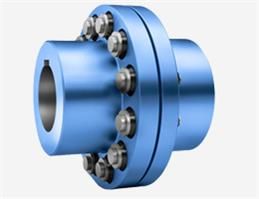

The horizointal axial flow pumps can be tailored produced according to the different requirements from our customers, some basic options of our axial pumps are listed as follow:

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Gear box |  | Reputed China brand | SEW, Shandong Chenghua, Zhengzhou machinery instituteSiemens, Flender |

| Flanges & counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

Agricultural Irrigation:

The feature of big flow rate and low head of axial flow pump makes those pumps suitable for transferring massive amount of water for farm irrigation purposes.

Flood Control:

Due to the capability of moving large volume of water in a short period of time, the axial flow pumps are widely used as flood water evacuation.

Cooling Water Circulation:

The big flow axial flow pumps are widely required as cooling water circulation pumps in many industries including chemical plants, power plants, oil refineries to circulate big amount of cooling water into the cooling water towers or heat exchangers.

Forced circulation Systems:

Due to the features of high efficiency and and flow rate, the axial flow pumps are suitable to work as forced circulation pumps in many industries where the forced circulation systems are required.

Wastewater Treatment:

The chemical axial flow pumps are ideal for wasterwater evaporation(MVR) due to their excellent capability of forced circulation in the evapoerating systems.

Aquaculture: The axial flow water pumps are the good choice for exchanging water in fish or shrimp farms effectively.

Company video

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

+86 28 8218 1182

-

+86 28 8218 1182