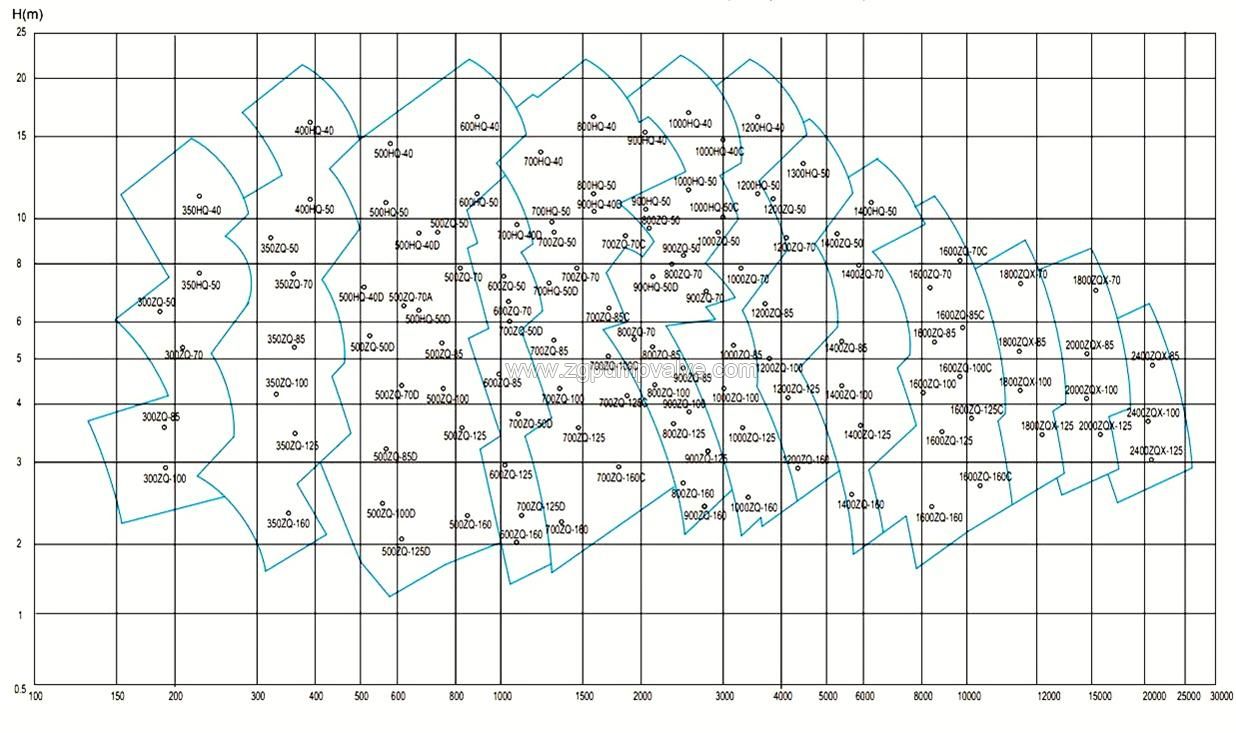

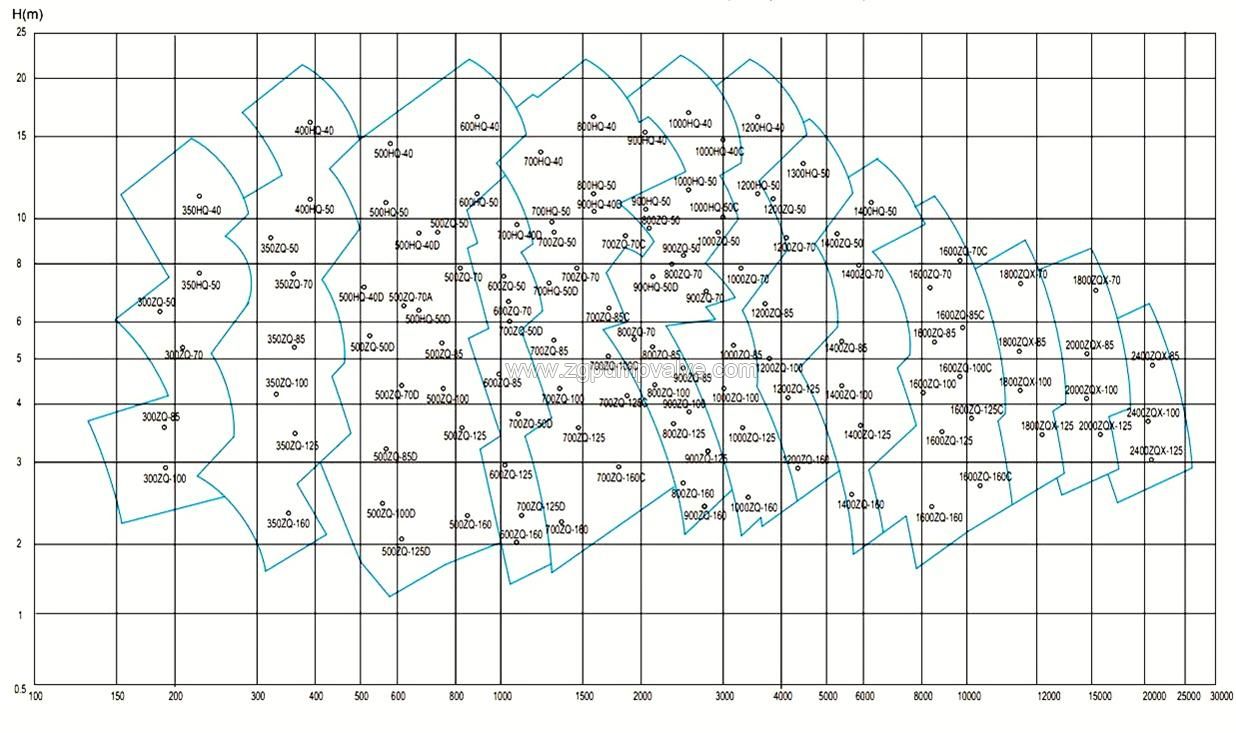

The submersible axial flow pumps have wide performance ranges which covers most of the applications where they can be used, below are the main parameters of those pumps.

■ Flow Rate:

The most important parameter of a those pumps is their flow rate, which features for large volume. Their flow rate typically ranges from 500 m3/hr to 38000 m3/hr.

■ Discharge Head:

Compared to large volume flow rate, the submersible axial flow pumps have distinguishing feature of low discharge head. The head value of those pumps often ranges from 1.5 to 20 meters

■ Motor Power:

Due to the feature of large volume capacity, those pumps are normally coupled with big power electric motors which range from 18.5 kW to 1120 kW.

■ Pump Speed:

Due to the wide performance range, their pump speed range covers 295 RPM to 1450 RPM with 50Hz motors.

■ Pump Efficiency:

Due to the optimized hydraulic designs, the submersible axial flow pumps have an advantage of high efficiency which ranges from 75% to 90%. It is recommended to operate those pumps at or near the best efficiency point to avoid the vibration or even cavitation.

■ Impeller Diameter:

The diameter of the propeller-like impeller is an important parameter of those pumps, as it directly affect the pump flow rate. The diameter of impellers ranges from DN350 to DN1600.

Submersible axial flow pumps have distinct features which make them outstanding compared to other type of pumps. This section shows the features and operational advantages that make those pumps ideal for various demanding applications in various industries.

■ Higher Pump Efficiency:

Compared to general centrifugal pumps, the submersible axial flow pumps always have higher pump efficiency due to the advanced hydraulic models.

■ Compact Structure:

Those submersible pumps have the pump part and motor part closely combined together, this design reduces the total pump length a lot to save the installation space.

■ Corrosion Resistant:

Those special designed and built pumps are for handling the corrosive fluids, as we have rich experience in selection of correct materials for those pumps.

■ Easy Installation:

Due to the column pipe which can guide the pump into its right position, the submersible axial flow pumps can be quickly installed.

■ Less Maintenance:

Due to the simple and robust structure design, they require less maintenance compared to other type of pumps.

■ Intelligent Monitoring:

To make sure the smooth operation, those pumps can be integrated with thermal sensors, moisture detection and vibration sensors.

■ Solids Handling Ability:

With special design to the flow passage and propeller of our submersible axial flow pumps, they have excellent ability to handle fluids with certain amount of solids or particles.

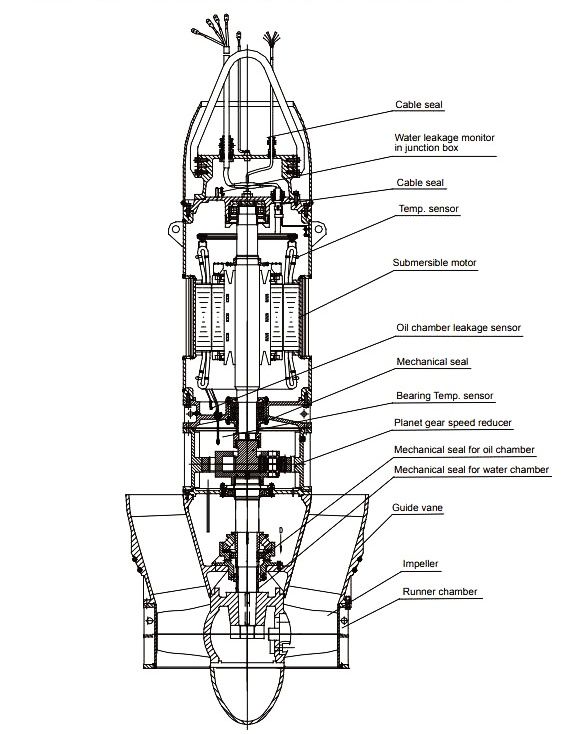

The unique design in structure of our submersible axial flow pumps is the precondition of the smooth operation in the water and long service life of those pumps.

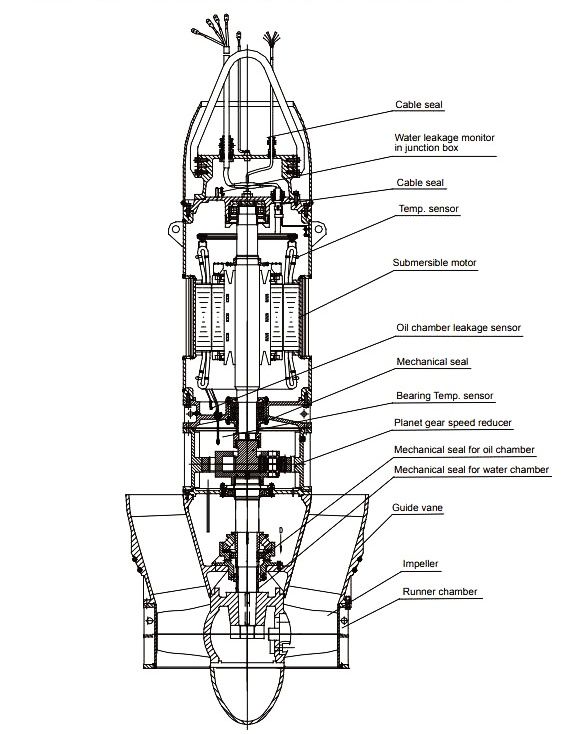

■ Motor Assembly:

With either water-filled or oil filled cooling system, higher insulation grade F or H and higher water-proof grade IP68, the motor of the submersible water pump is able to function well even if working underwater.

■ Pump Configuration:

With angle-adjustable blades design of the propeller, those pumps are able to work at various flow rate and discharge head based on the requirements of applications.

■ Sealing System:

Cartride double mechanical seals with suitable materials including silicon carbide or hardened alloys, along with the mositure detection chambers, are the essentail configurations of the sealing system of an submersible axial flow pump

■ Bearing Arrangement:

With the design of self-lubricating bearings, the pump can work stably with less vibration and noise.

■ Monitoring Integration:

With the integrated sensors of temperature monitoring, moisture detection and vibration inspection, our submersible axial flow pumps can avoid many potential issues before happening.

The correct material selection of submersible axial flow pumps are the essential precondition of long service life and optimal performance.

■ Motor Housing: Typically made from cast iron or ductile cast iron, but available with stainless steels or even higher grade materials.

■ Impeller & Guide Vane: For better anti-cavitation considerations, the impeller is recommended to be constructed from stainless steel SS304, SS316, SS316L, or super duplex stainless steels

■ Shaft Assembly: For consideration of rusting issues of rotation partof submersible axial flow pumps, at least SS420 is recommended as the shaft material.

■ Bearing Selection: Bearings with special design with self-lubricating function is the key factor to enable the smooth rotation of shaft.

■ Shaft sealing: Mechanical seals made from silicon carbide or tungsten carbide have excellent wear resistant performance.

■ Cable Construction: Electric cables integrated with EPR insulation, mechanical protection and water blocking, are the precondition of safe operation.

We offer flexible configurations, which means we can customize the submersible axial flow pumps to match your exact requirements.

■ Drive Options: 50 Hz or 60 Hz – depends on the local grid

■ Motor Brand: Reputable Chinese brands or Western brands- both are available

■ Bearings: Reputable Chinese brands or Western brands- both are available

■ Pump Arrangement: Horizontal or vertical installation – according to the design of site

■ Pump Wetted Parts MOC: Typically made from Cast Iron- but optional with stainless steels

■ Control Systems: From basic PLC to smart SCADA systems – depends on the budget of clients

■ Monitoring Package: Vibration sensors and temperature sensors– for predictive maintenance

Our Submersible Axial Flow Pumps can be found working in many industries, below are some typical applications where they are widely used.

■ Water Treatment Plants: Those submersible pumps are normally used as circulation pumps in the pits.

■ Cooling Systems: They are used for handling of large amount of water for the cooling towers in power plants.

■ Chemical Plants: They are also popular in various chemical plants where they are handling the corrosive fluids.

■ Irrigation & Farming: Those big capacity pumps are suitable for transfering large amount of water in a short period of time.

■ Municipal Projects: Widely used in the waterworks, the submersible axial flow pumps are an essential pumping device for water supply projects.

The spectrum of QZ/QH submersible axial flow pumps