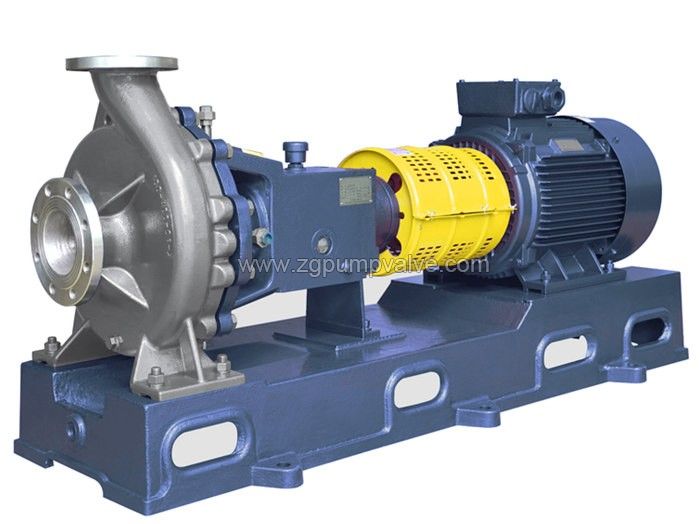

Chemical Pump

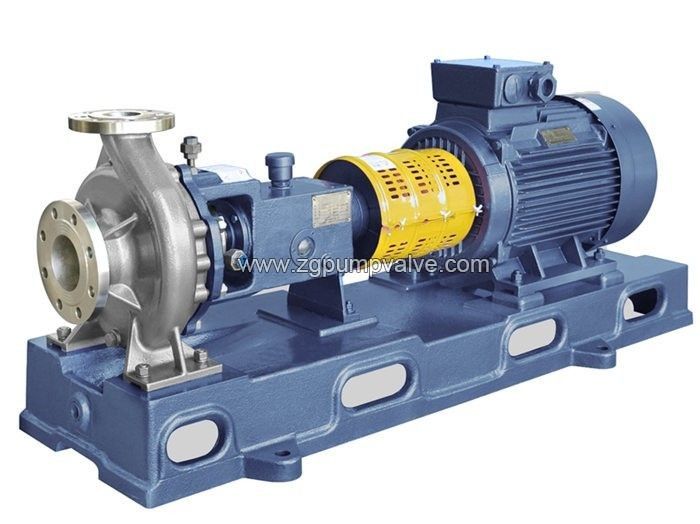

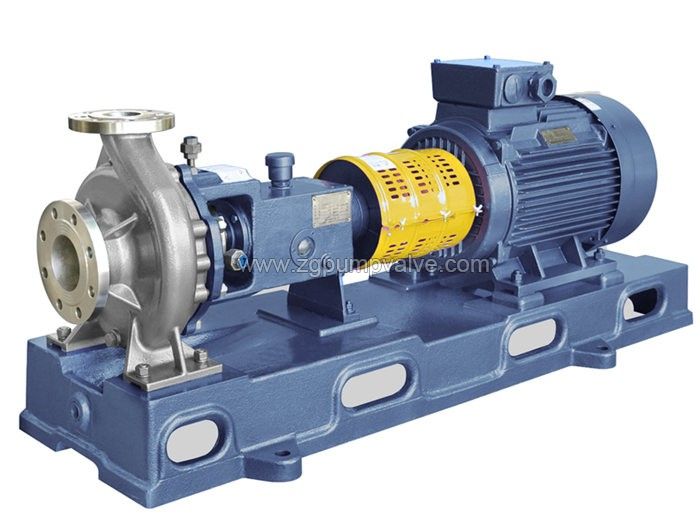

Titanium Centrifugal Pump

The Titanium centrifugal pumps are end suction centrifugal pumps which wetted parts material is entirely made from Titanium or Titanium alloys. Due to the excellent performance of corrosion resistance, the Titanium centrifugal pumps are widely used to handle harsh mediums including high temperature caustic soda, brine, seawater process...With features of light-weighted and high strength material, those titanium pumps are able to work for long service life with low maintenance. Therefore, the titanium centrifugal pumps become the essential pumping devices in demanding industries including chemical process, marine and offshore platforms.

-

Parameters

-

Features

-

Structure

-

MOC

-

Configuration

-

Application

-

Performance

Titanium centrifugal pumps are the important pumping devices for salt plants, marine process, seawater desalination plants and other chemical processes, where those titanium pumps are widely used to handle high temperature and highly corrosive fluids.

Flow rate:Q=0.8~2500 (m³/h)

Total head:H=3~300 (m)

Speed:n=1450/2900rpm

Temperature:T=-80~425℃

S.g.:γ≤1.85

Pump diameter:50~350mm

Max. pressure:7.5Mpa

In chemical plants, Titanium centrifugal pumps are ideal for efficiently moving the corrosive mediums. Their light-weighted but robust feature ensures the trouble free operation and extends their service life. Some key features of our Titanium centrifugal pumps:

■ High efficiency.

■ Light-weighted pump body.

■ Back pull out design, easy maintenance.

■ Self-locking impeller nut.

■ Thickened heavy duty shaft

■ Enlarged bearing housing

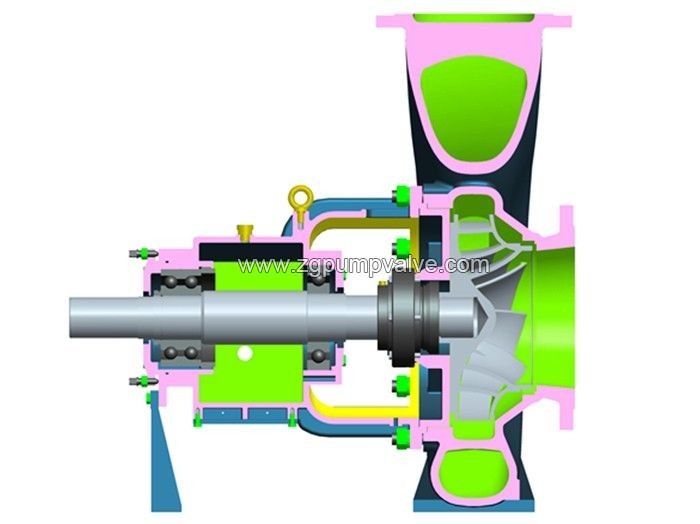

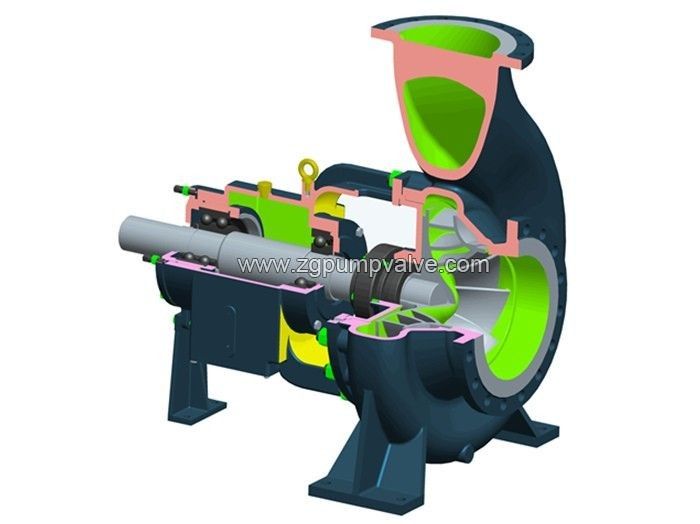

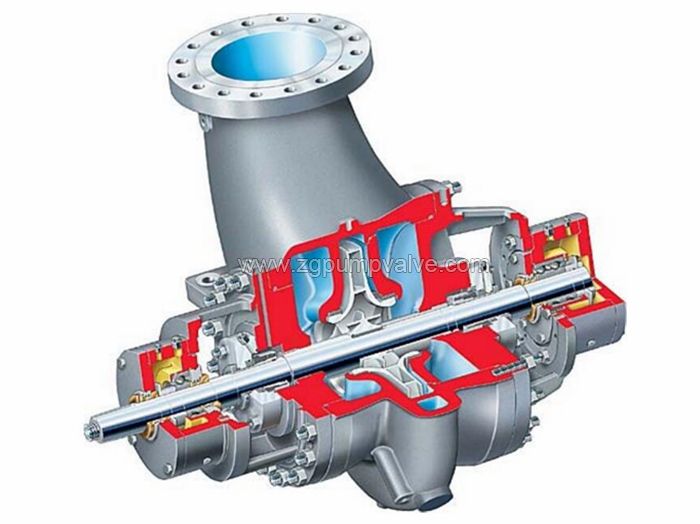

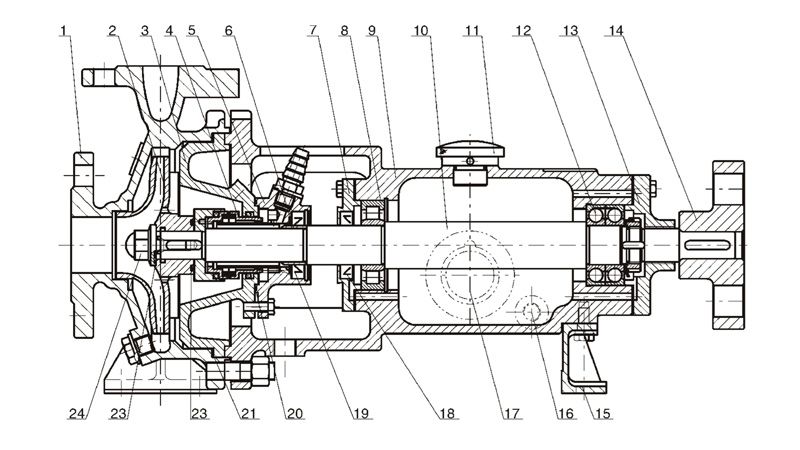

The essential components of centrifugal titanium pumps including pump casing, impeller, mechanical seal and shaft. Below are some basic introduction of the main parts of our titanium pumps:

■ Pump Casing: A titanium made pump body that converts fluid velocity into pressure.

■ Impeller: The rotating titanium impeller component that passes energy to the fluid.

■ Shaft: The part connects the impeller and motor, can be made from Titanium.

■ Bearing & Seal System: Fixes the shaft and mechanical seals to prevent potential leakage.

■ Back Cover: Allows the inspection of the internal parts in the pump casing

The pump structure of a centrifugal titanium pump is as follows:

1.Pump casing 2.Impeller 3.Pump cover 4.Mechanical seal 5.Seal end gland 6.Wear sleeve 7.Front bearing gland8.Front bearing | 9. Bearing housing 10. Shaft 11. Air vent cover 12. Back bearing 13. Back bearing gland 14. Pump coupling 15. Bracket 16.Pipe plug | 17. Oil-analysis standard 18. Skeleton oil seal 19. Skeleton oil seal 20. O ring of seal end gland 21. Pump cover washer/O ring 22. O ring of impeller 23. O ring of impeller nut 24. Impeller nut |

The Titanium Centrifugal Pump is specially made from titanium or titanium alloys in various grades, however as a chemical centrifugal pump, its wetted parts material also can be customized as other materials including austenitic stainless steels, duplex stainless steels, Monel, Alloy 20...

| No. | Description | Material | |||||

| Anti-corrosion alloy | Cast steel | Stainless steel | |||||

China standard | ASTM standard | China standard | ASTM standard | China standard | ASTM standard | ||

| 1 | Pump casing | 20# Alloy Titanium Nickel 904L Ti/Pd Alloy Monel | Hastelloy Monel Ⅱ-B Ⅱ-C Ni-Resist1 Ni-Resist2 Ni-Resist3 | 25# 35# | WCA WCB | ZG1Cr13 ZG2Cr13 ZG00Cr18Ni10 ZG0Cr18Ni9 ZG0Cr18Ni12Mo2Ti ZG0Cr17Ni4CuNb ZG1Cr18Ni9 ZG1Cr18Ni9Ti ZG00Cr17Ni14Mo2 0Cr26Ni5Mo2 0Cr17Mn13Mo2N 00Cr18Ni5Mo3Si2 | CA-15 CA-15M CF-3(SS304L) CF-8(SS304) CF-8M(SS316) CF-3M(SS316L) CN-7M(SS320) CD-4MCu 2205 |

| 2 | Sealing ring | ||||||

| 3 | Impeller | ||||||

| 4 | Pump cover | ||||||

| 5 | Impeller nut | ||||||

| 6 | Cartridge seal | ||||||

| 7 | Shaft | Carbon steel SS420 2205 SS304 SS316 | |||||

| 8 | Bearing Housing | Cast iron | |||||

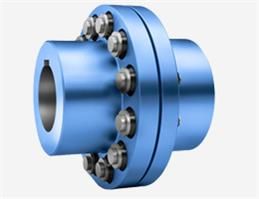

Titanium centrifugal chemical pumps are typically end suction pump with back pull out design, below are some configurations available for our titanium pumps:

| Item | Factory standard | Optional configurations | |

| Motor |  | Reputed China brands | ABB, Siemens, Nanyany, Jiamusi or designated brands |

| Bearing |  | Reputed China brand | SKF, NSF, FAG or designated brands |

| Mechanical seal |  | Zigong brand | Burgmann, Sihuan Riji, Chengdu Yitong |

| Flanges&counter flanges |  | China standard | European std, German std, American std, Japanese std |

| Couplings |  | Pin type | Flexible diaphragm coupling |

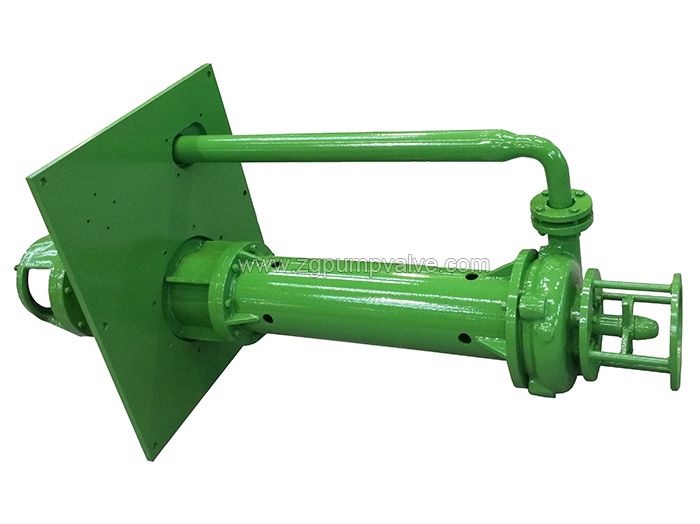

Due to the excellent performance of corrosion resistance, our Titanium Centrifugal Pumps are widely used in various industries.

■ Chemical Processing: Transferring highly corrosive chemical solutions in tanks, reactors, evaporators...

■ Marine & Offshore: Ideal for seawater transferring, desalination process and firefighting systems.

■ Power Plants: Seawater cooling circulation systems of FGD.

■ Oil & Gas: Transferring corrosive fluid including high content of chloride ions.

■ Pharmaceutical & Food: Suitable for corrosion resistant applications

Company video

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

End Suction Pump Selection: An Ultimate Guide 2025-ZGPV Presents

-

What Is A Self-Priming Pump? An Ultimate Guide-ZGPV Presents

-

Solución de Problemas en Bombas Sumergibles: Guía Definitiva 2025

-

End Suction Pump vs. Inline Pump: What Are The Differences?

-

Vertical Seawater Pumps Run At Optimal Hydraulic Efficiency Steadily

-

+86 28 8218 1182

-

+86 28 8218 1182